Machining technology of piston on CNC machine tool

A processing technology and machine tool technology, which is applied in the processing technology field of pistons on CNC machine tools, can solve the problems of large opening and inability to process the profile surface of the wedge, and achieve the effects of reducing scrap, high processing accuracy, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

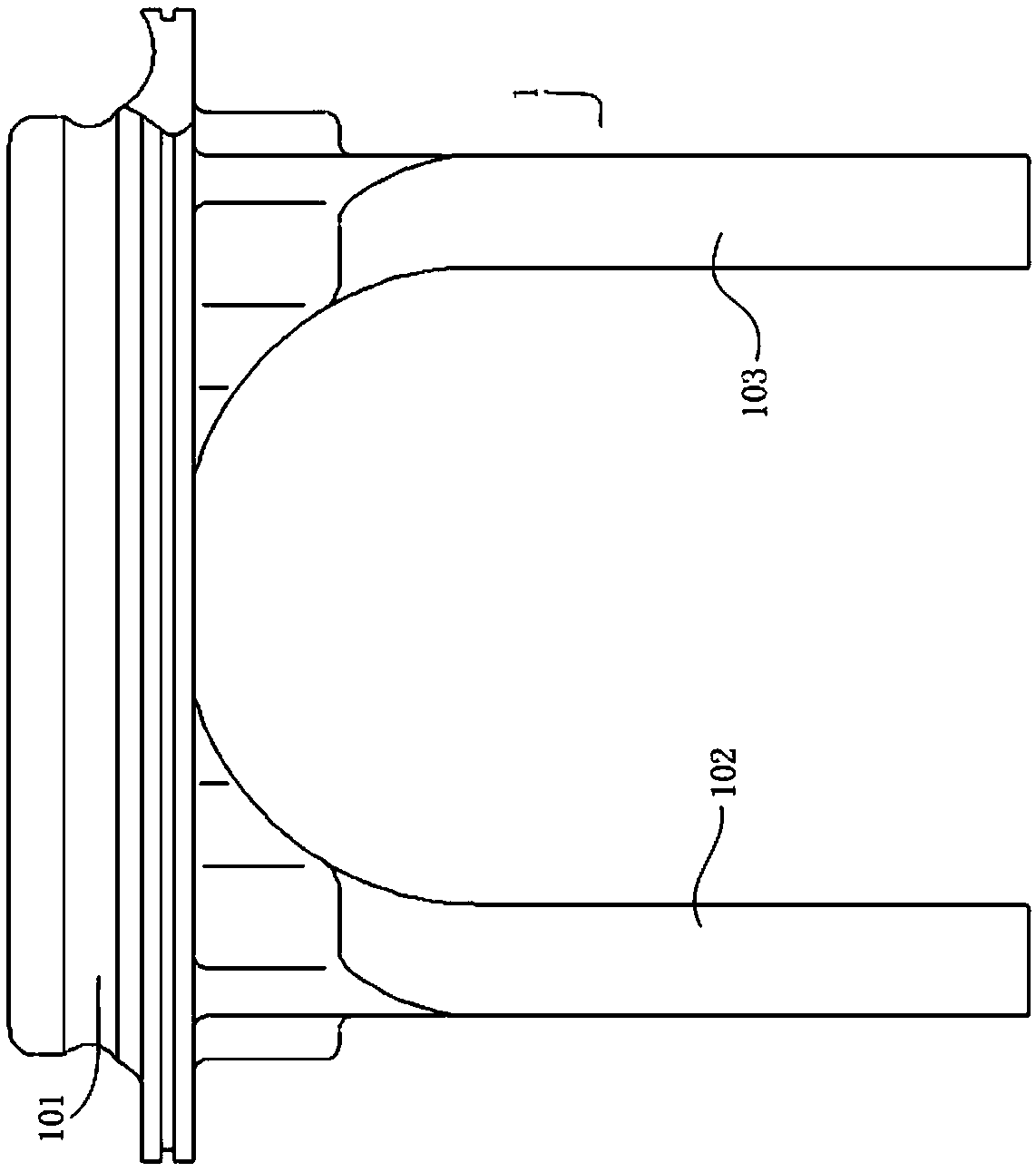

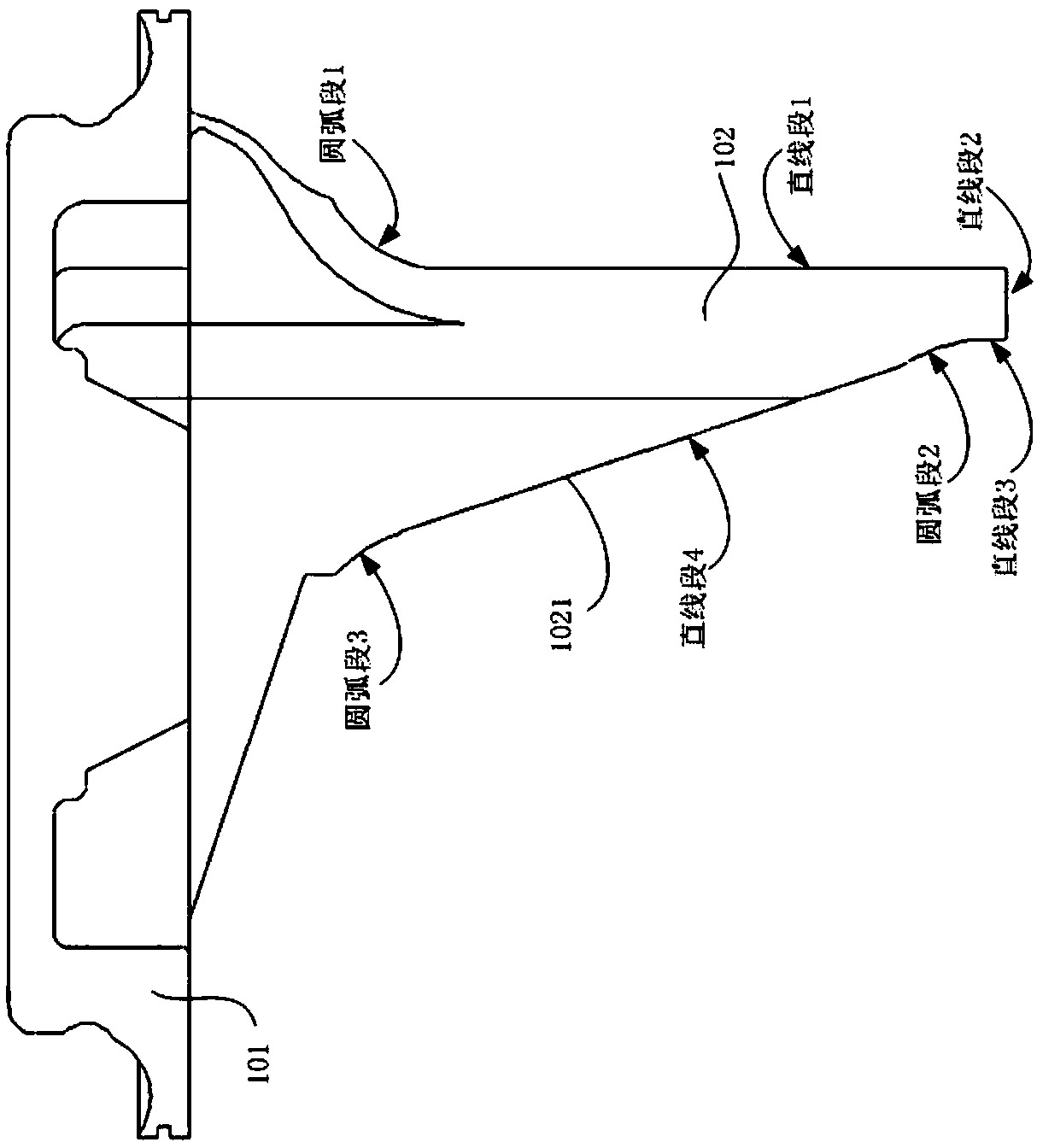

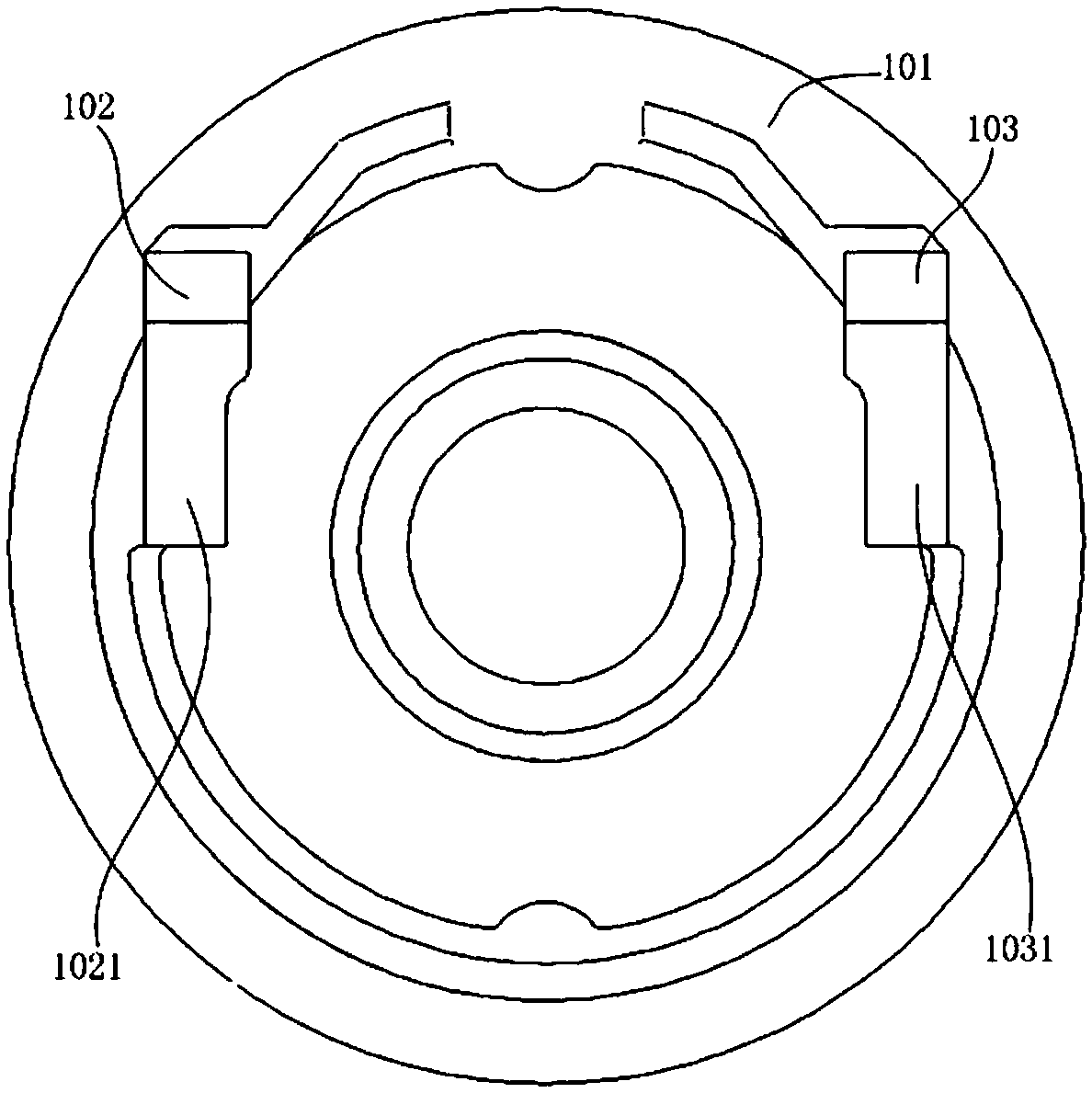

[0028] Please refer to Figure 1 to Figure 4 In the embodiment of the present invention, the piston 1 includes a head seat 101 and a first wedge angle 102 and a second wedge angle 103 symmetrically formed on the head seat 101 . The machining process of the piston in the embodiment of the present invention on the CNC machine tool is used to process the wedge profile surface 1021 of the first wedge angle 102 and the wedge profile surface 1031 of the second wedge angle 103 on the piston 1, and the wedge profile surface 1031 of the first wedge angle The contour surface 1021 and the oblique wedge contour surface 1031 of the second wedge angle are arranged symmetrically and have the same shape.

[0029] Please refer to Figure 1 to Figure 8 , the process step of the present invention is:

[0030] Step a), in the automatic programming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com