Mold spraying frame

A technology of spraying racks and molds, applied in the direction of spraying devices, etc., can solve the problems of untimely opening and closing, complex equipment, uneven atomization, etc., and achieve the effects of preventing paint waste, ensuring sealing performance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

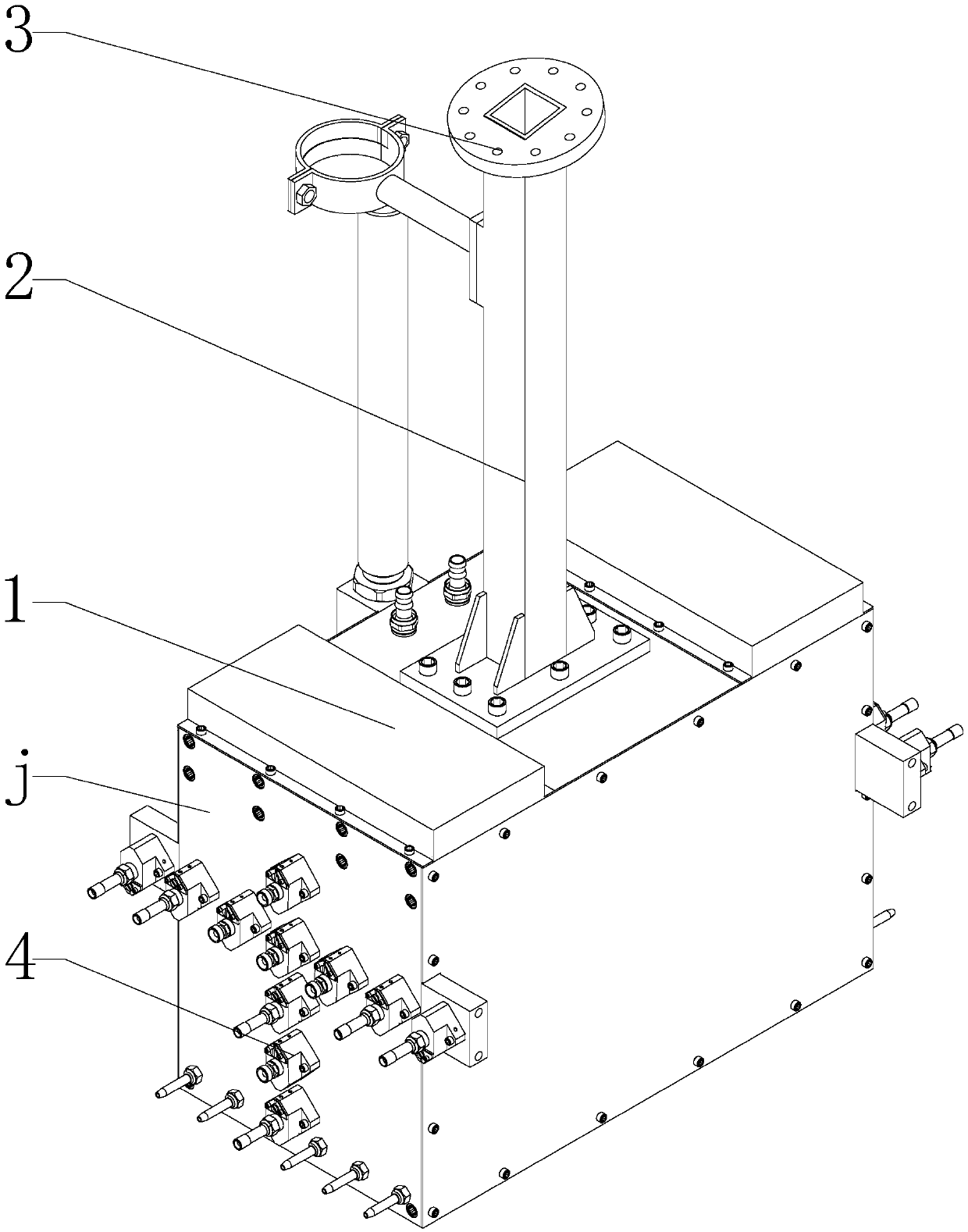

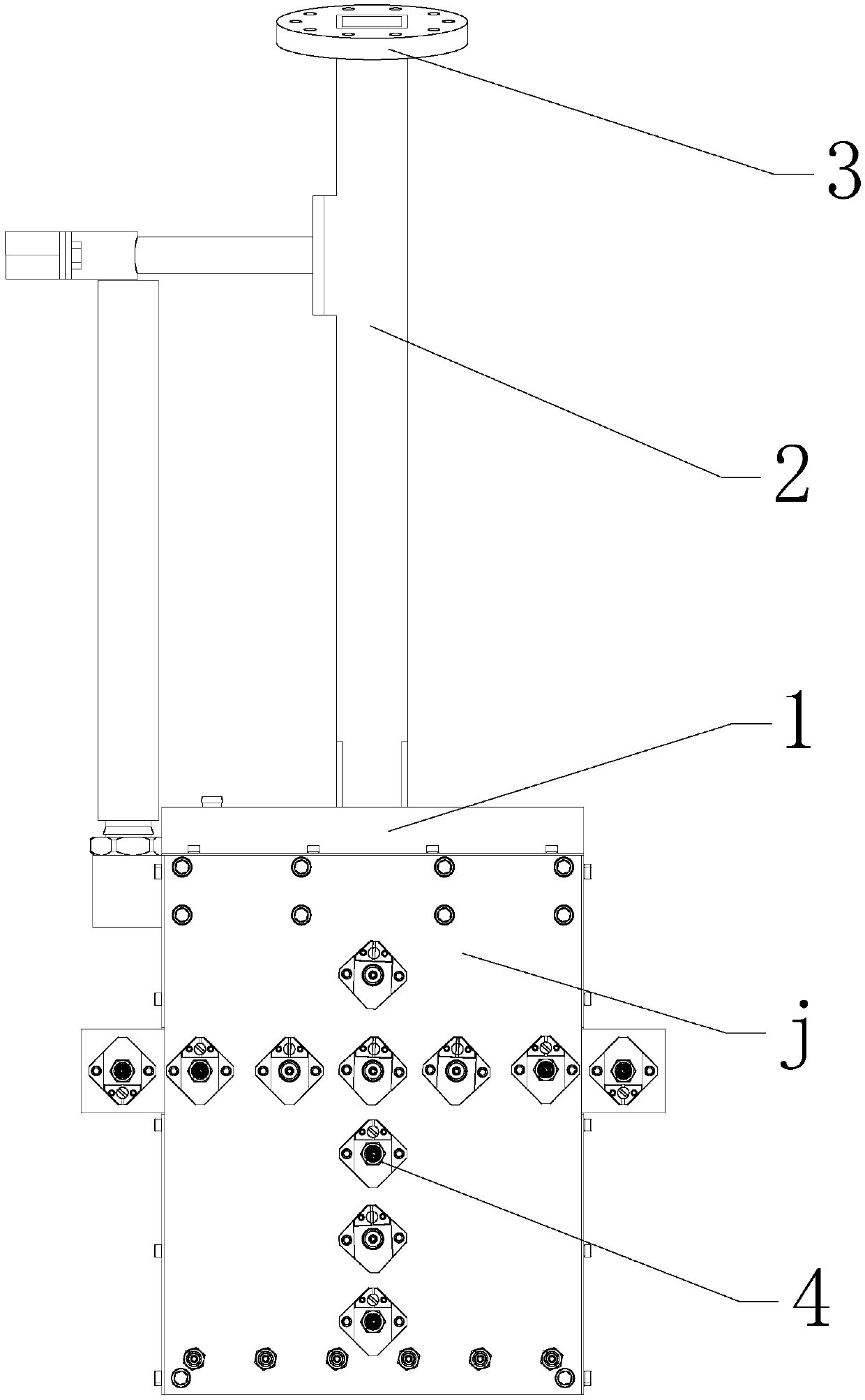

[0063] Such as Figure 1-12 As shown, a kind of mold spraying stand, its key is: comprise spraying base 1, spraying base 1 is connected with cantilever 2, cantilever 2 one end is connected with spraying base 1, and the other end end is provided with connecting plate 3, and connecting plate 3 is provided with There are screw holes, and the spraying seat 1 is provided with at least one spraying facade j, and the spraying facade j is provided with a horizontal nozzle group and a vertical nozzle group, and the horizontal nozzle group is composed of a plurality of horizontally arranged nozzles 4, and the vertical nozzle group It consists of multiple nozzles 4 arranged vertically.

[0064] The spraying seat 1 includes a cubic box, and two opposite vertical sides of the box form a spraying facade j, on which the horizontal nozzle group and the vertical nozzle group are arranged in a "cross" shape.

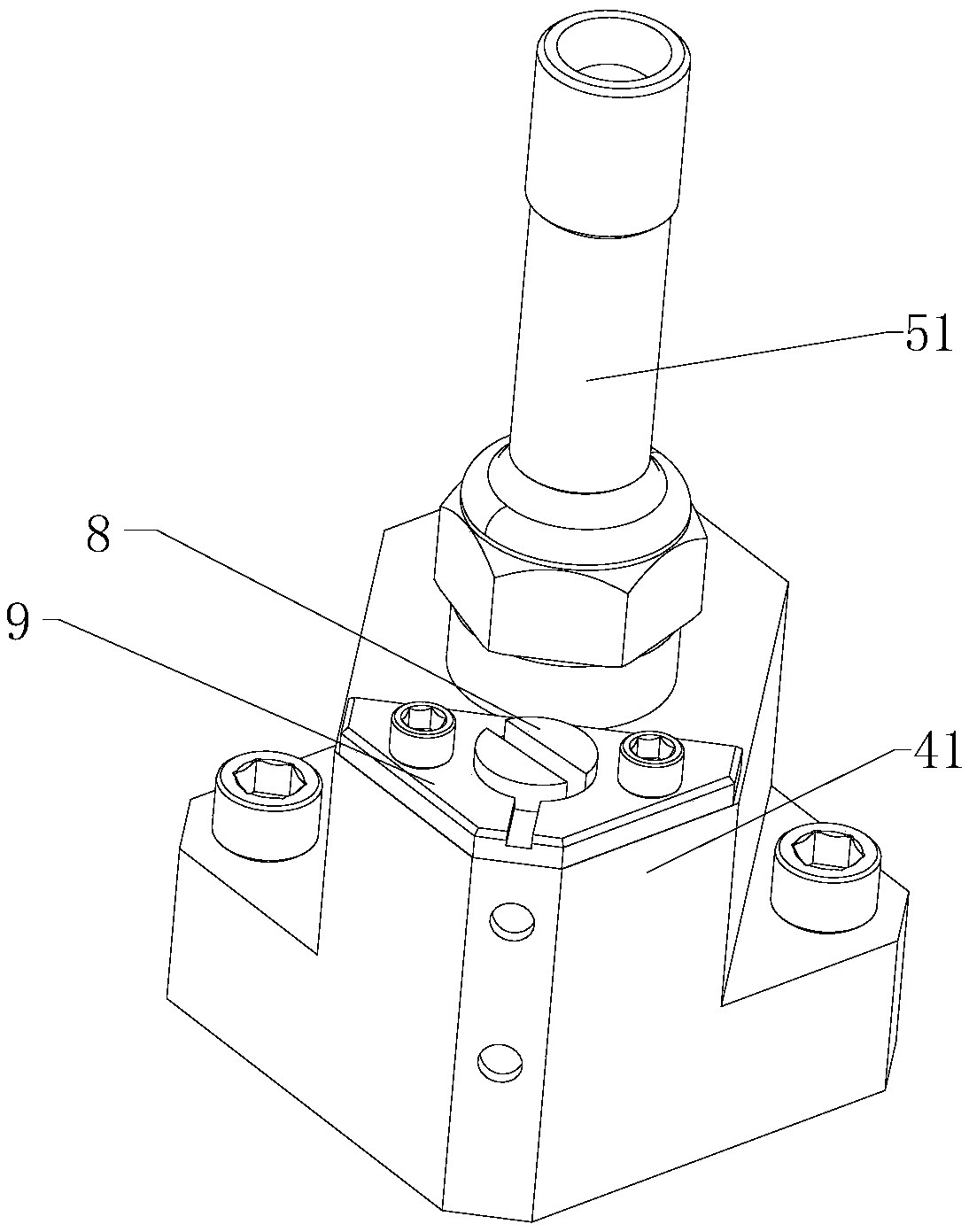

[0065] The nozzle 4 includes a nozzle seat 41, the nozzle seat 41 is provided with a...

Embodiment approach

[0083] One of the implementation methods is: the diameter ratio of the direct current hole o to the constriction hole q is 2:1, the diameter ratio of the atomization hole s to the constriction hole q is 4.3:1, the axial length of the constriction hole q and its diameter The ratio is 1.8:1, the axial length of the contraction extension tube 10 and the axial length of the contraction hole q are 1:1, and the ratio of the outer diameter of the contraction extension tube 10 to the diameter of the atomization hole s is 2:1.

[0084] Another embodiment is: the diameter ratio of the direct current hole o to the constriction hole q is 2.5:1, the diameter ratio of the atomization hole s to the constriction hole q is 4.8:1, the axial length of the constriction hole q and its diameter The ratio is 2.2:1, the axial length of the contraction extension tube 10 and the axial length of the contraction hole q are 1:1, and the ratio of the outer diameter of the contraction extension tube 10 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com