Magnetic covalent organic framework compound solid phase extraction adsorbent and preparation method

A technology of covalent organic framework and adsorbent, which is applied in the field of analytical chemistry and food safety detection, can solve the problems of restricting the wide application of materials, and achieve the advantages of simple and fast preparation method, good solvent stability, low detection limit and quantification limit Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of magnetic solid phase extraction adsorbent based on COF material

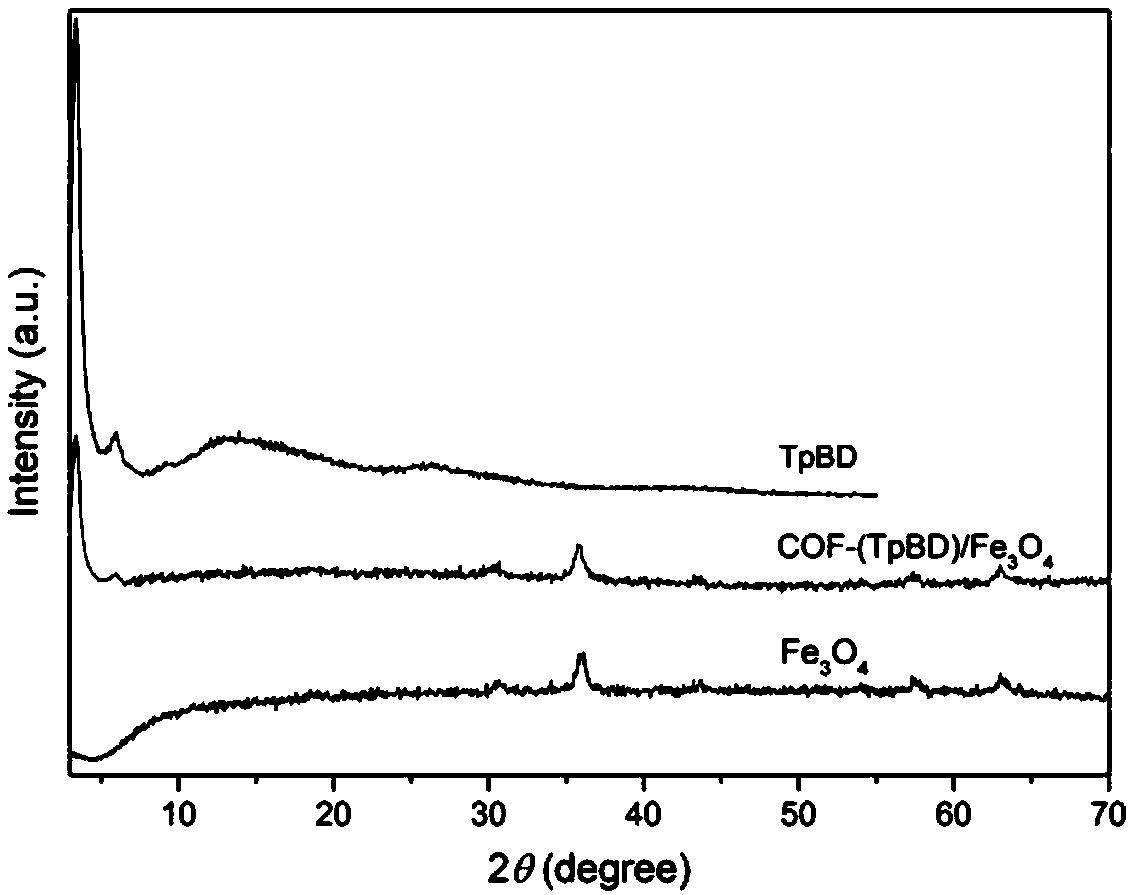

[0060] (1) Preparation of COF materials: Stable covalent organic framework compound materials are generated by solvothermal reaction. The selected COF material is COF-TpBD, and the raw materials used in the synthesis are 63 mg (0.3 mmol) of trialdehyde phloroglucinol (Tp) and 48 mg (0.45 mmol) of benzidine (BD). The organic solution used in the synthesis was 3 mL of mesitylene, 3 mL of 1,4-dioxane, and the catalyst was 0.3 mL of 6M acetic acid solution. The above-mentioned materials were ultrasonically mixed and then transferred into a Teflon reactor, and reacted at 120° C. for 72 hours. The material was taken out, washed repeatedly with acetone, and dried in vacuum for later use.

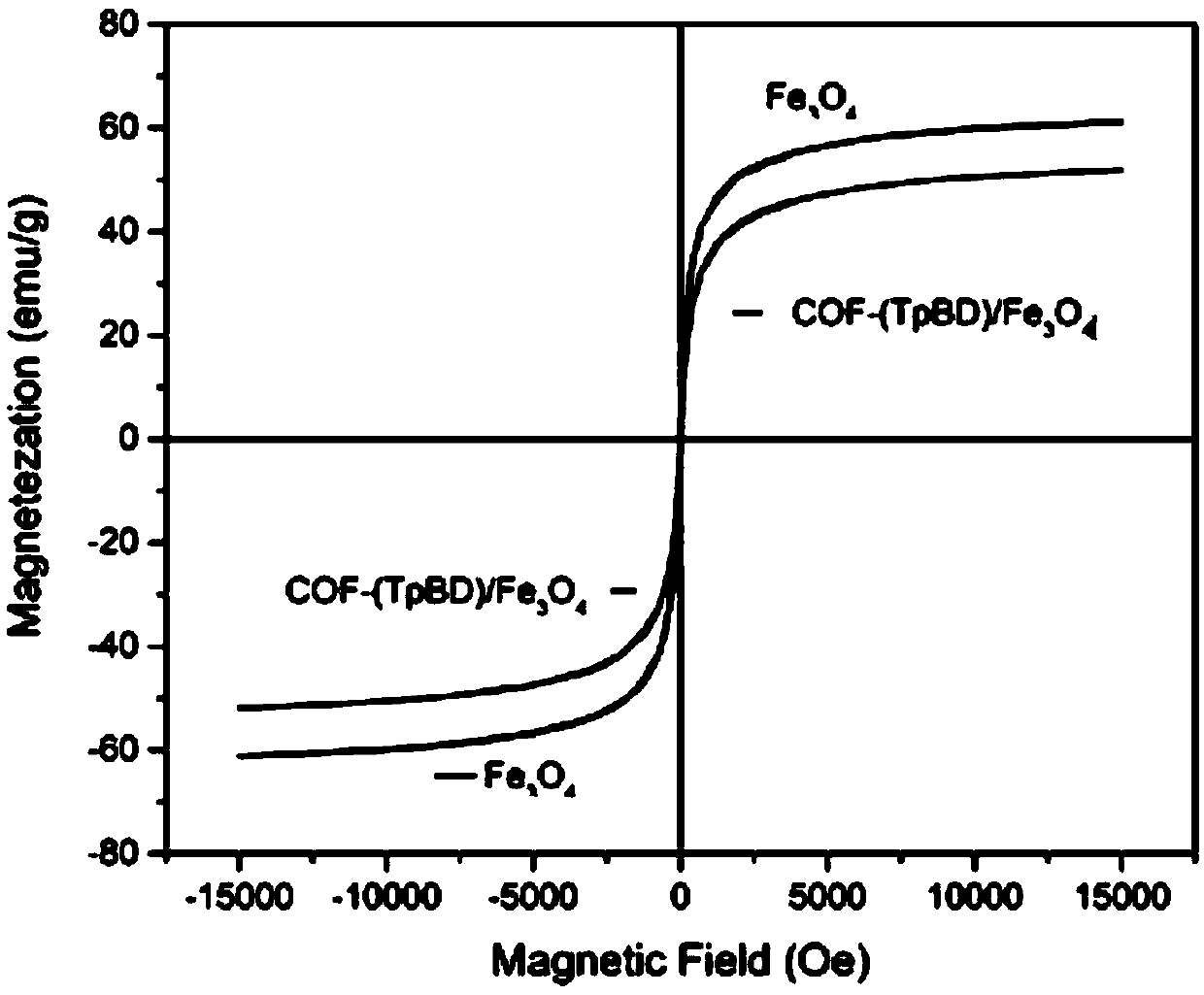

[0061] (2) Magnetization of COF materials: Synthesis of COF-(TpBD) / Fe by co-precipitation method 3 o 4 . Ferric chloride hexahydrate (FeCl 3 ·6H 2 O) 0.4g, ferrous sulfate heptahydrate (FeSO 4...

Embodiment 2

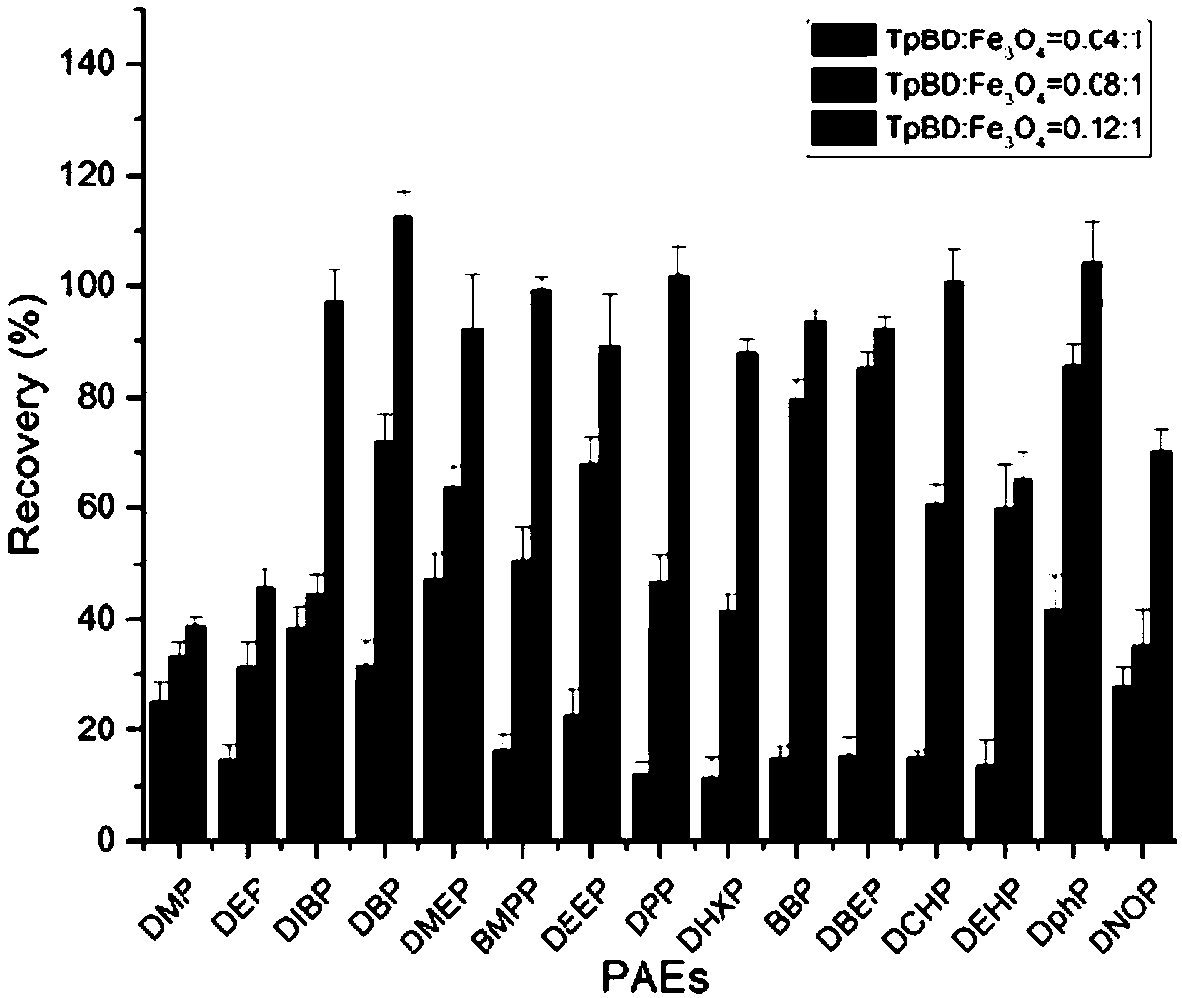

[0066] With reference to embodiment 1, the present invention adopts single factor test to COF-TpBD and synthetic Fe 3 o 4 The feed ratio of the iron source raw materials is optimized and inspected, by figure 1 It can be seen that the feed ratio has a great influence on the extraction and adsorption performance of the material. The adsorption effect is generally poor when the mass ratio is below 0.04:1, not exceeding 10%, and the adsorption performance is gradually improved when the mass ratio is above 0.04:1. When the ratio is 0.12:1, the adsorption effect of various compounds can reach 100%.

Embodiment 3

[0067] Example 3: Using COF-(TpBD) / Fe 3 o 4 Extraction and detection of 15 kinds of PAEs in beverage samples

[0068] (1) Standard solution preparation: PAEs-methanol standard solution with a concentration of 1000mg / mL, including DMP / DEP / DIBP / DBP / DMEP / BMPP / DEEP / DPP / DHXP / BBP / DBEP / DCHP / DEHP / DphP / DNOP gradient Dilute to 100mg / mL, 10mg / mL, respectively as stock solution and intermediate solution. The concentration of the working solution for the standard curve is 5 μg / mL, 10 μg / mL, 20 μg / mL, 50 μg / mL, 100 μg / mL, 200 μg / mL, 500 μg / mL, 1000 μg / mL, ready for use.

[0069] (2) Pretreatment of samples to be tested

[0070] Beer, carbonated drinks and alcoholic carbonated drinks are degassed in an ultrasonic bath to eliminate carbon dioxide. Then, drinks with complex matrix such as milk drinks, fruit juices and milk tea are diluted with pure water at a ratio of 1:8, and other beverages are diluted with pure water at a ratio of 1:5 to reduce matrix interference before the extraction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com