Chip test fixture

A technology of chip testing and fixtures, which is applied in the direction of electronic circuit testing, measuring electronics, measuring devices, etc., can solve the problems of limited test stations, fixed size, general protection performance of chip test fixtures, etc., and achieve good use effect and good protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

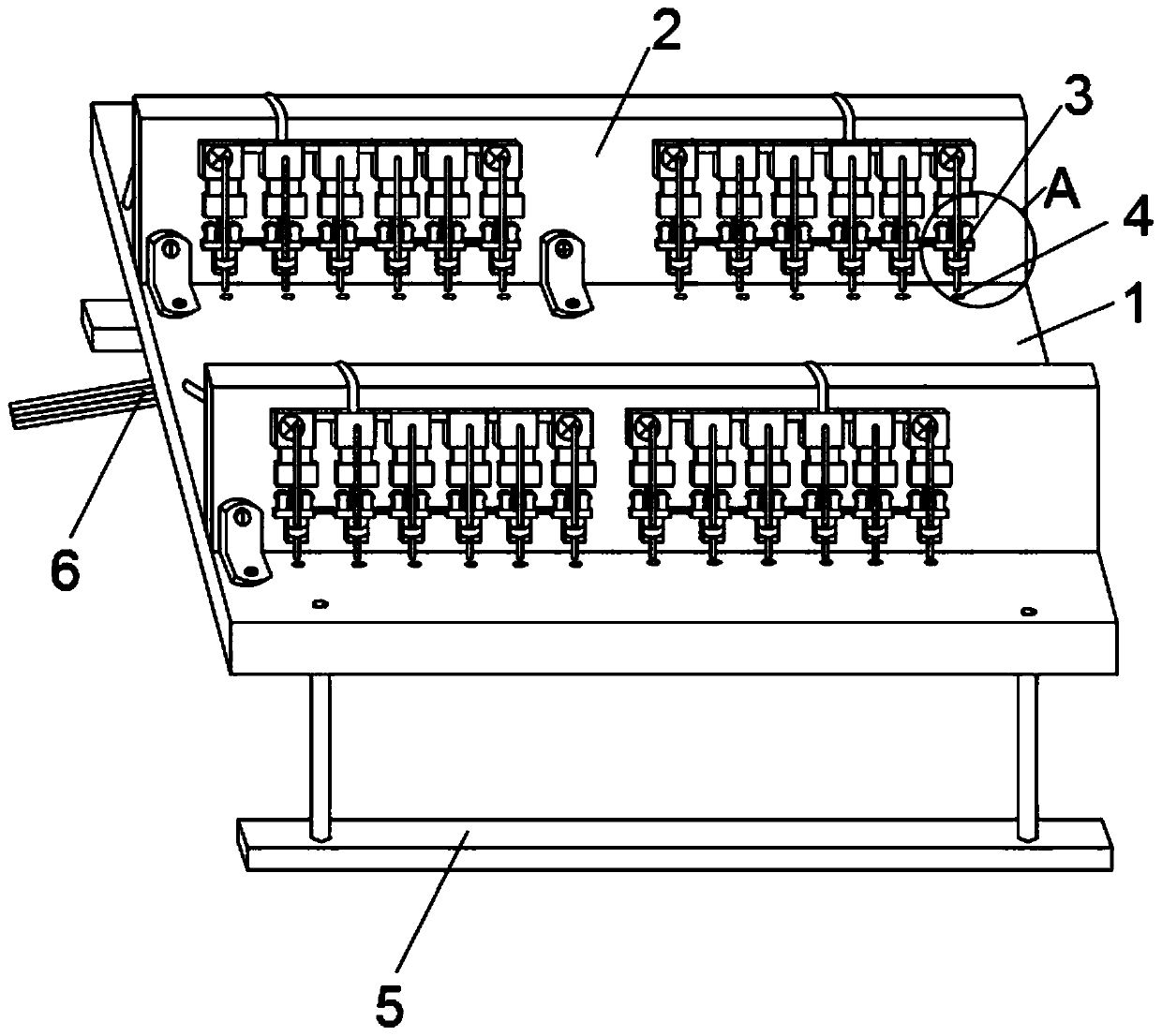

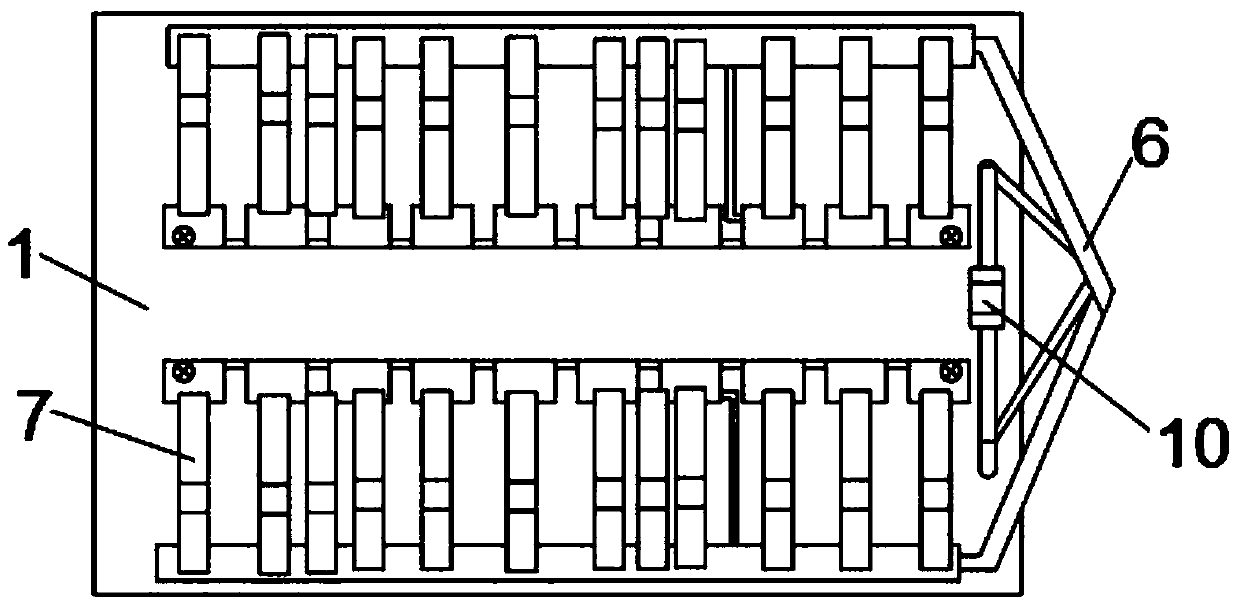

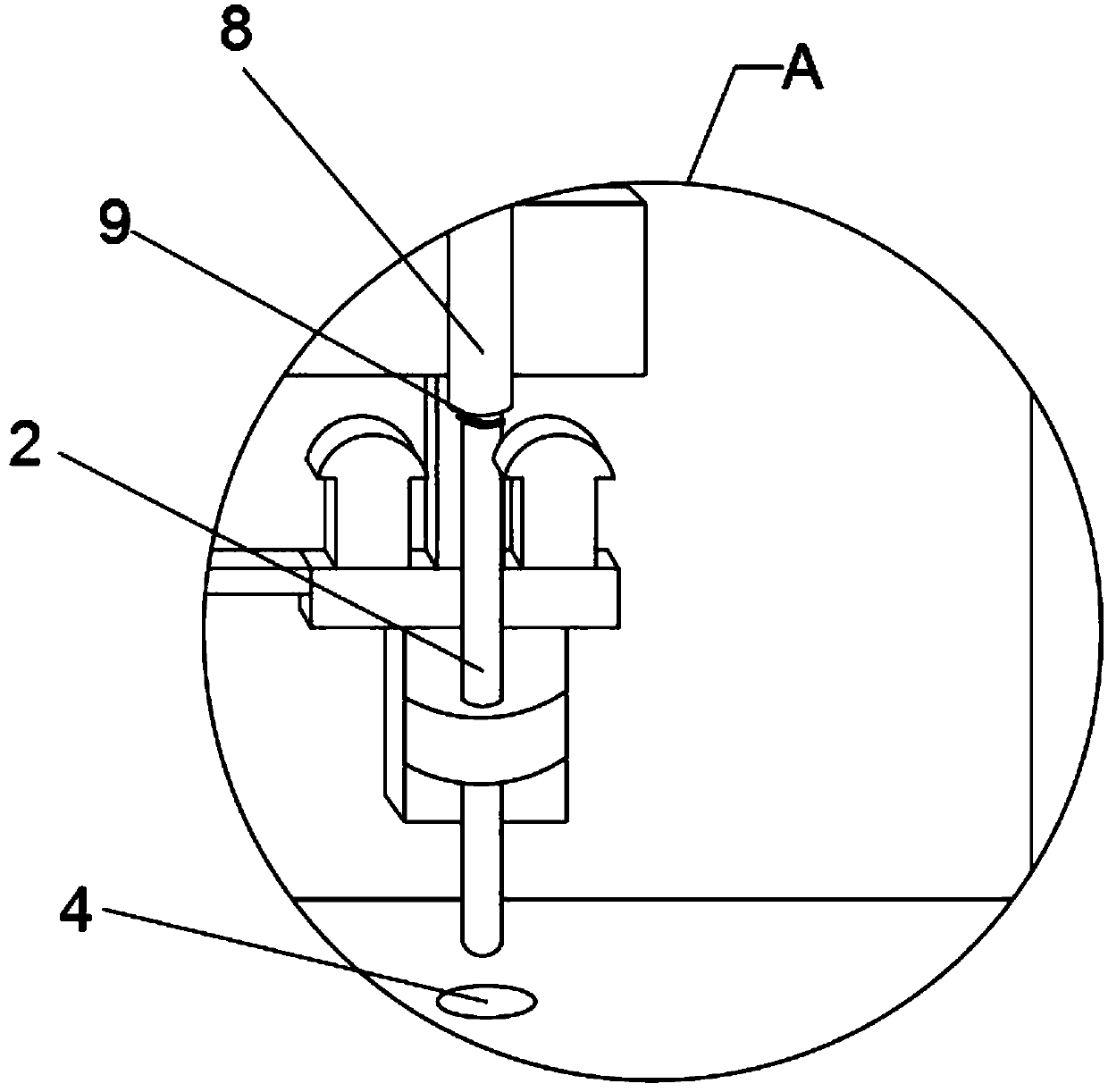

[0023] Such as Figure 1-3 As shown, a chip test fixture includes a test seat 1, two groups of fixed plates 2 are fixedly installed on the upper surface of the test seat 1, and the front surface and the rear surface of the fixed plate 2 are provided with test probes 3, and the test seat 1 The inner side of the upper surface of the test seat 1 is embedded with contact pins 4, the lower surface of the test seat 1 is fixedly installed with two sets of support feet 5, and the upper surface of the test seat 1 is provided with a signal line 6;

[0024] The lower surface of the test seat 1 is provided with a fuse 7 corresponding to the lower end of the contact pin 4, and a test needle cover 8 is installed on the upper periphery of the test probe 3, and the inner surface of the test needle cover 8 is connected to the outer surface of the test probe 3. A return spring 9 is wrapped between them, and the return spring 9 can return the test probe 3 to its original position when the test p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com