Electrical automation device for industrial inspection

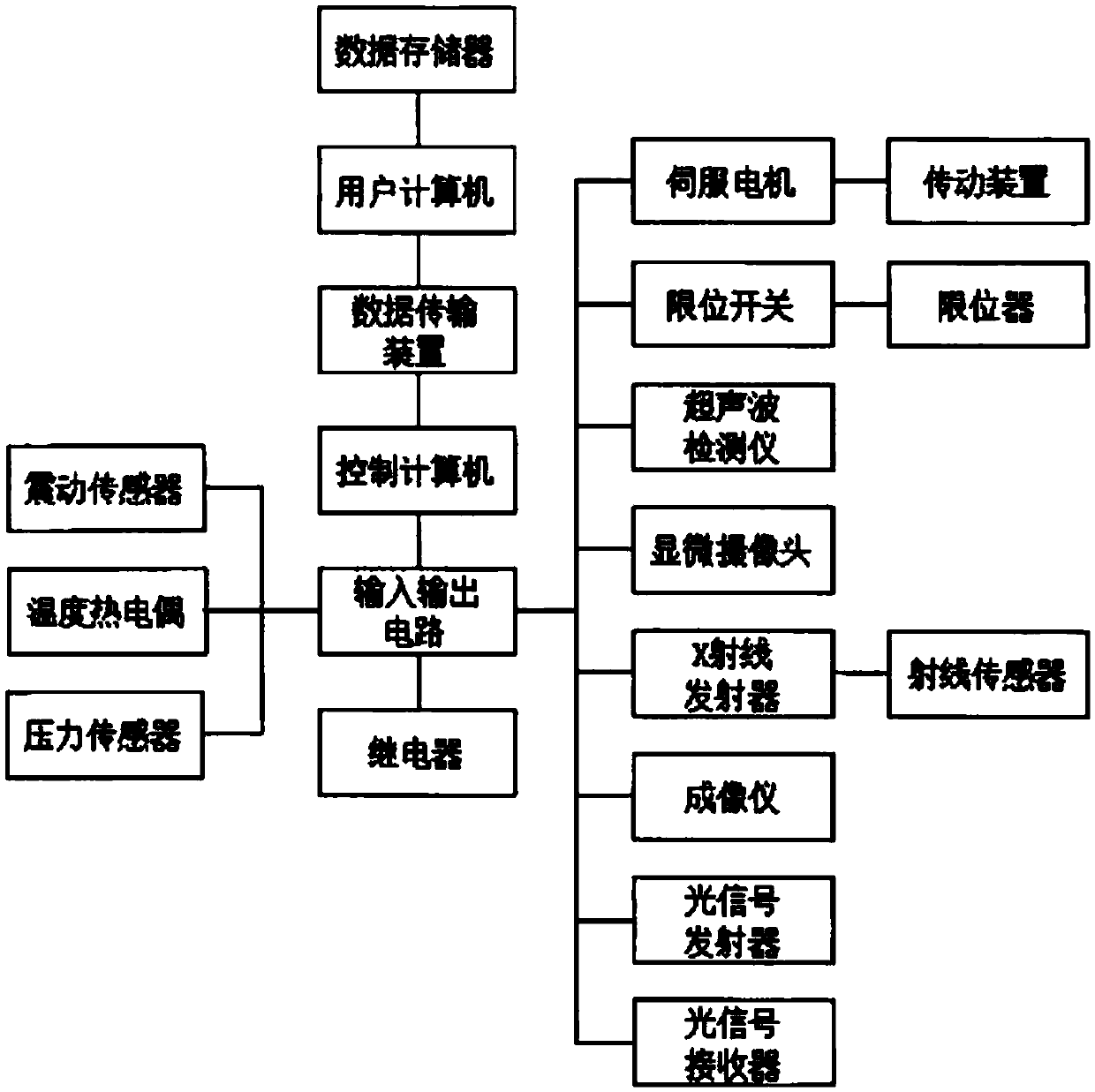

A technology of electrical automation and transmission, which is applied in the direction of optical testing for flaws/defects, material analysis using radiation, and solid analysis using sound waves/ultrasonic waves/infrasonic waves, etc. Data and other issues, to achieve the effect of speed control and good data support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] Put the product to be inspected on the transmission device, the servo motor drives the transmission device to run, and the speed of the servo motor can be controlled by controlling the computer. When the position of the required detection item is reached, the limit switch controls the limiter to work, and the transmission device Stop, the product to be inspected stops to the desired position.

[0017] (1) Ultrasonic testing: Ultrasonic testing can be used for ultrasonic testing of defects that are invisible to the naked eye on the surface of the product to be tested, such as bumps and cracks.

[0018] (2) Partial microscopic inspection: The microscopic camera can be used to take pictures and image the parts of the product to be inspected or the suspicious parts after other inspections.

[0019] (3) X-ray inspection: use X-ray emitters and imagers, through the penetration of X-rays, conduct ray-penetrative inspections of internal defects such as cracks and protrusions th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com