A Variable Stiffness Electromagnetic Particle Damper

A particle damper and variable stiffness technology, which is applied in the direction of building types, buildings, building components, etc., can solve problems such as inability to achieve optimization and numerical simulation, difficulty in meeting shock absorption requirements, complex nonlinear characteristics, etc., and facilitate numerical simulation Analysis, dynamic damping effect, avoiding the effect of non-linear characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

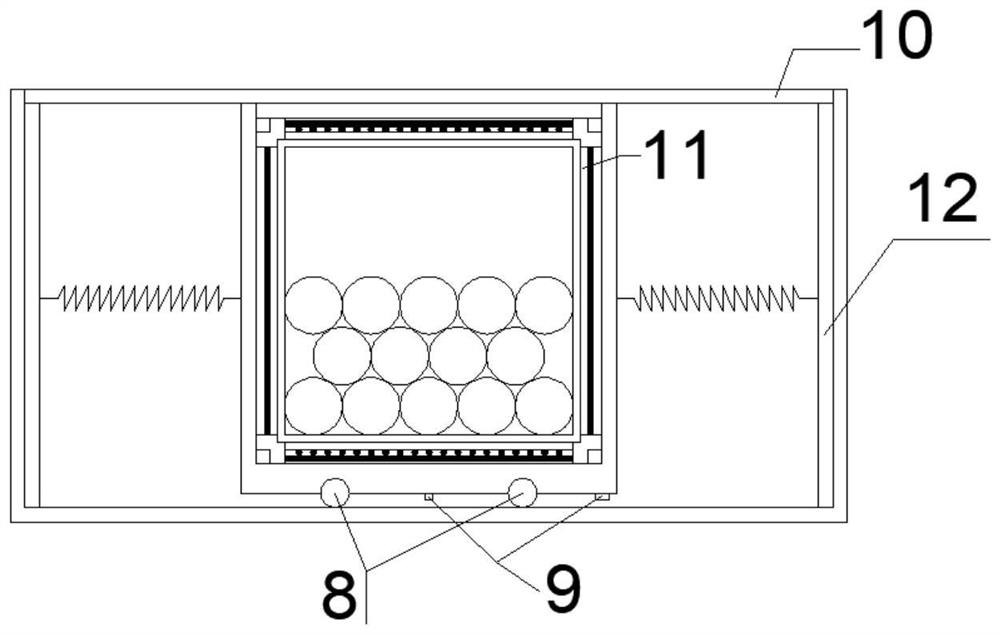

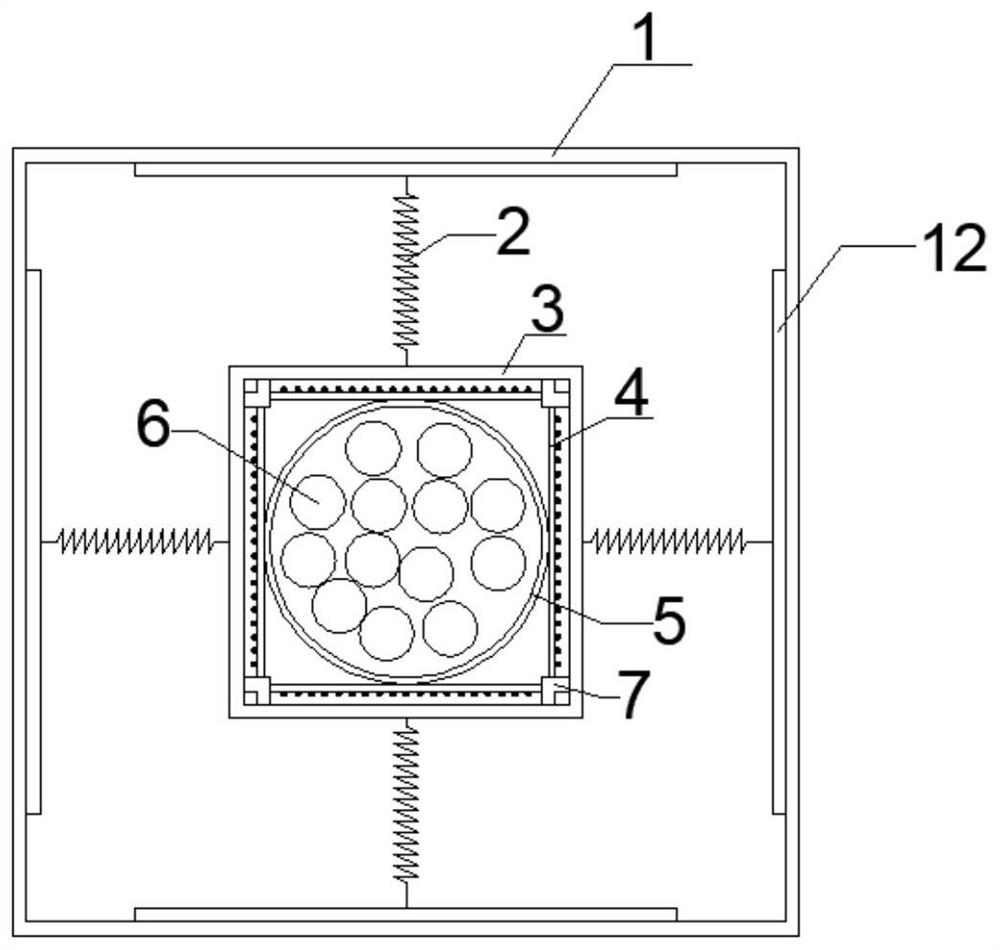

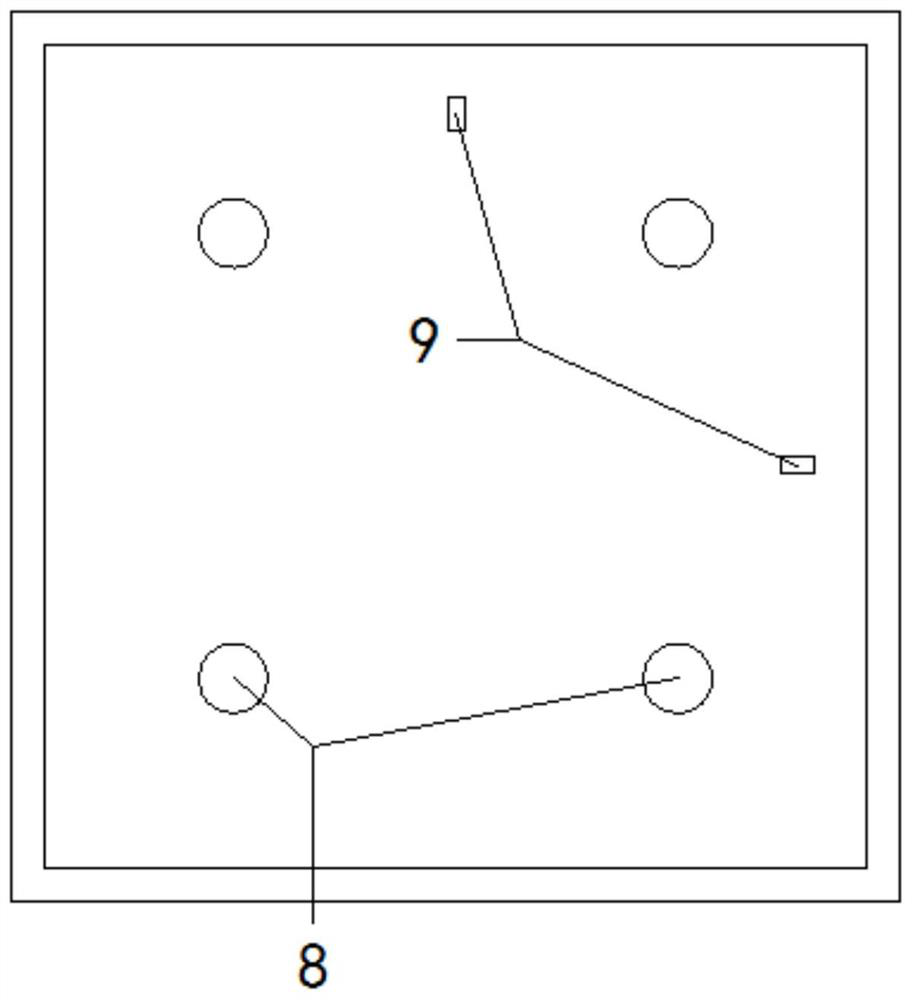

[0027] An electromagnetic particle damper with variable stiffness, which can be fixed on the top or bottom of the structure to be damped, and its structure is as follows figure 1 , 2 shown. In this embodiment, the size of the fixed box 1 is 1160×1160×600 mm, the thickness of the side wall is 20 mm, the fixed box 1 is placed on the ground, and the top is sealed by the box cover 10 . The size of the outer box 3 is 520×520×540mm, its wall thickness is 20mm, the size of the inner box 11 is 410×410×410mm, its wall thickness is 10mm, the diameter of the cylinder 5 is 400mm, its height is 400mm, its thickness is 10mm. The diameter of the inner particle 6 is taken as 80 mm, and manganese zinc ferrite is used. The outer box 3 is connected to the fixed copper plate 12 on the inner wall of the fixed box 1 through four springs 2 with variable stiffness.

[0028] The inner box 11 is placed in the outer box 3, and is limited and fixed by the limiting device 7. There is a certain gap in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com