External switch blade type fiber bundle cutting-off mechanism for beam intensity machine and application

A technology of cutting mechanism and beam strength meter, which is applied in the direction of fiber bundle into fiber sliver/yarn, textile material inspection, textile and paper making, etc. It can solve the problems of inaccurate cutting, large error fluctuation, troublesome operation, etc., and achieve Accurate measurement and calculation, precise cutting process, convenient mechanism use and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

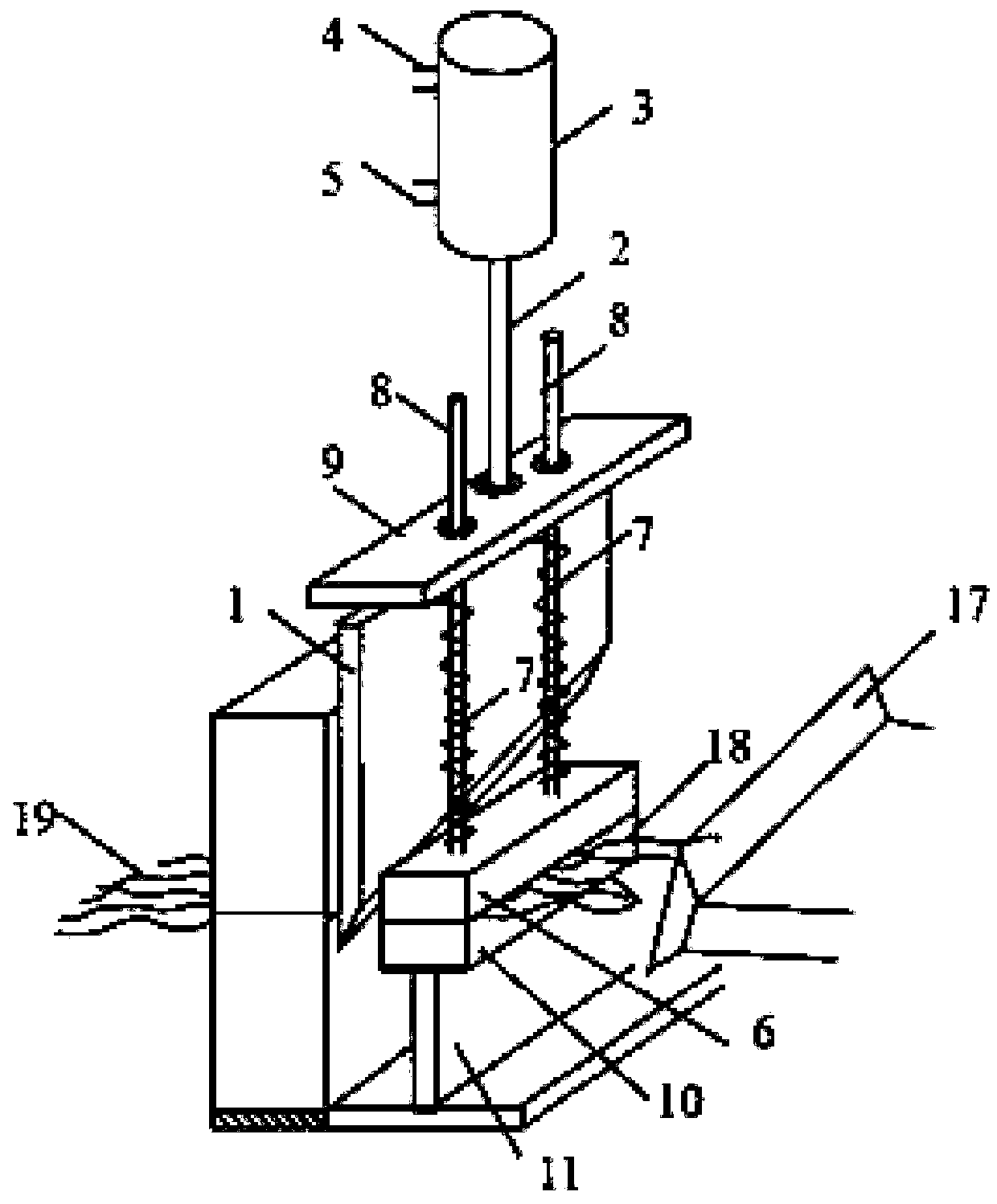

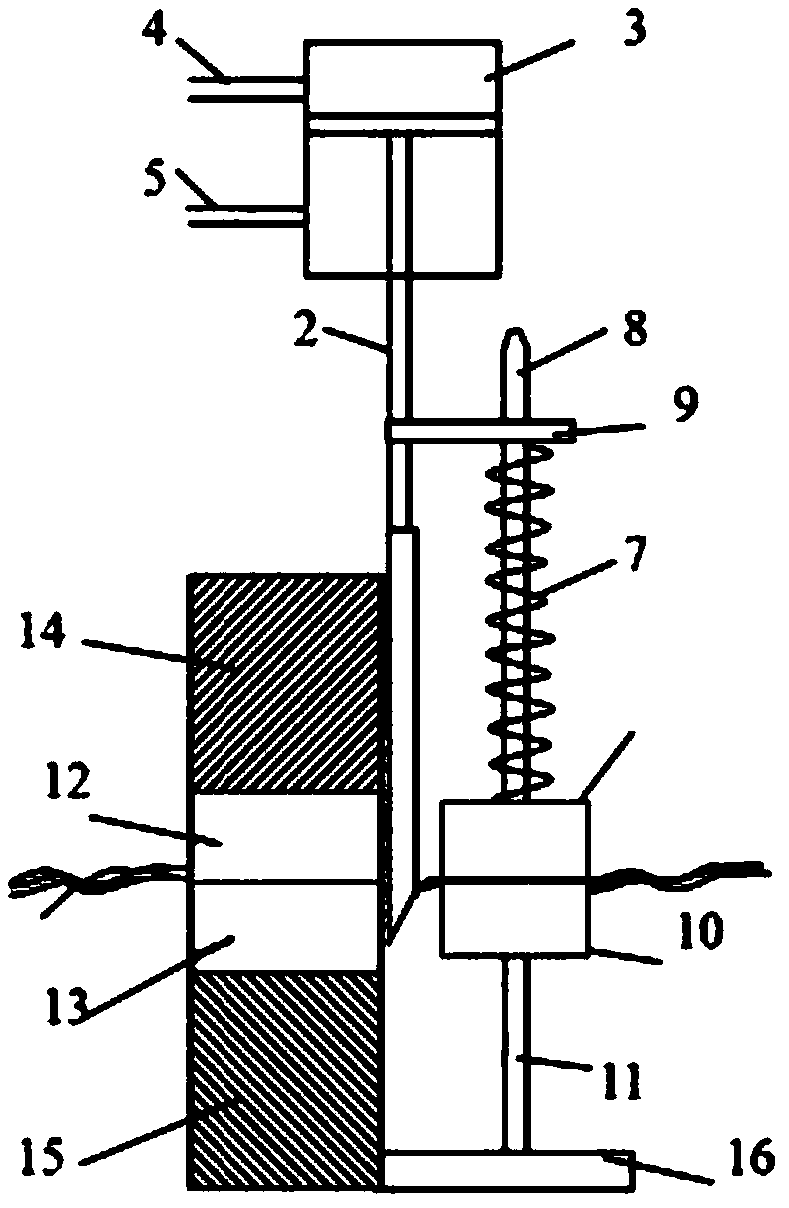

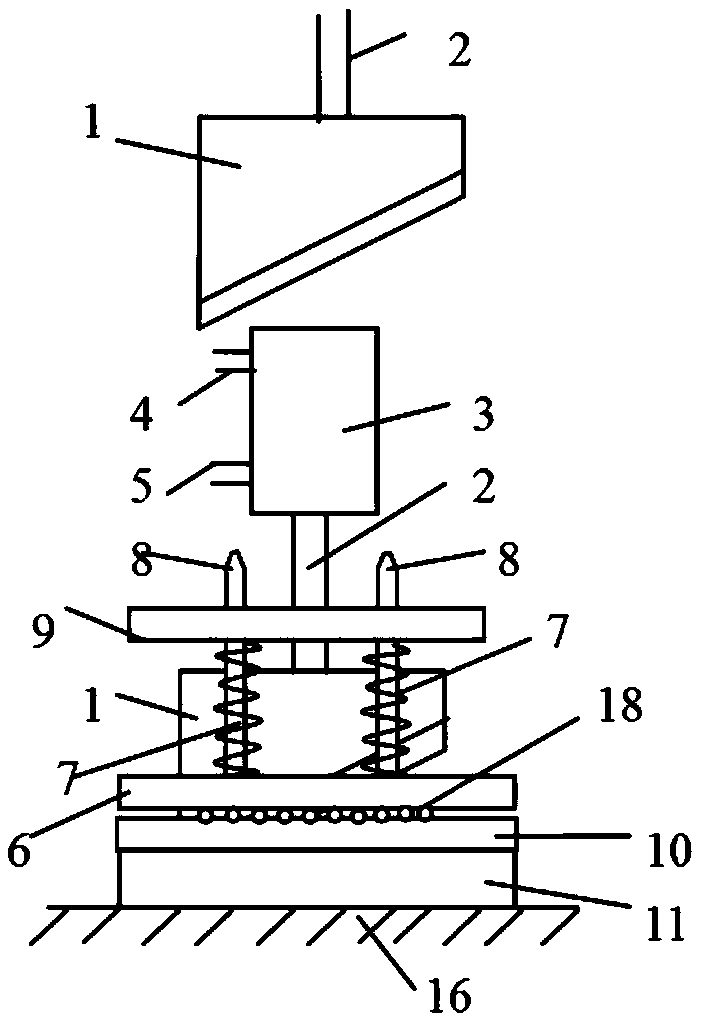

Embodiment 1

[0032] The embodiment uses 66 combed wool (2114 μm) to test. Environmental conditions of the experiment: the temperature is 20° C., and the relative humidity is 65%. The fibers of the wool bundle are first clamped between the upper chuck 12 and the lower chuck 13 at a fixed distance, and the two ends of the grown fibers are naturally laid directly on the surface of the lower bead 10. 1 and the compression spring seat 9 move downward accordingly. Before the knife 1 touches the fiber, the compression spring seat 9 acts on the upper pressing plate 6 by squeezing the compression spring, so that the upper pressing plate 6 and the lower pressing plate 10 are closed and clamped. bundle of fibers. The switch knife 1 continues to descend, and the bundle fibers are cut sequentially. Finally, the air suction port 17 collects the cut fibers 18 .

Embodiment 2

[0034] Embodiment Adopt ramie (fineness is 0.9tex, length is 36.2mm) test. Environmental conditions of the experiment: the temperature is 20° C., and the relative humidity is 65%. The ramie bundle fibers are first clamped between the upper chuck 12 and the lower chuck 13 at a fixed distance, and the two ends of the grown fibers are naturally laid on the surface of the lower bead 10. 1 and the compression spring seat 9 move downward accordingly. Before the knife 1 touches the fiber, the compression spring seat 9 acts on the upper pressing plate 6 by squeezing the compression spring, so that the upper pressing plate 6 and the lower pressing plate 10 are closed and clamped. bundle of fibers. The switch knife 1 continues to descend, and the bundle fibers are cut sequentially. Finally, the air suction port 17 collects the cut fibers 18 .

Embodiment 3

[0036] The embodiment adopts carbon fiber 2.2K test. Environmental conditions of the experiment: the temperature is 20° C., and the relative humidity is 65%. The carbon bundle fiber is first clamped between the upper clamp 12 and the lower clamp 13 at a fixed distance, and the two ends of the grown fiber are naturally laid directly on the surface of the lower bead 10. 1 and the compression spring seat 9 move downward accordingly. Before the knife 1 touches the fiber, the compression spring seat 9 acts on the upper pressing plate 6 by squeezing the compression spring, so that the upper pressing plate 6 and the lower pressing plate 10 are closed and clamped. bundle of fibers. The switch knife 1 continues to descend, and the bundle fibers are cut sequentially. Finally, the air suction port 17 collects the cut fibers 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com