Electroplating equipment for improving PCB high-aspect-ratio hole-filling capacity and copper plating uniformity

A PCB board with high thickness-to-diameter ratio technology, which is applied in the field of electroplating equipment to improve the ability of filling holes with high thickness-to-diameter ratio of PCB boards and the uniformity of copper plating. It can solve the problems of uneven surface copper thickness, high cost, and uneven hole copper thickness. To achieve the effect of increasing uniform fluidity, improving longitudinal fluidity, and ensuring penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

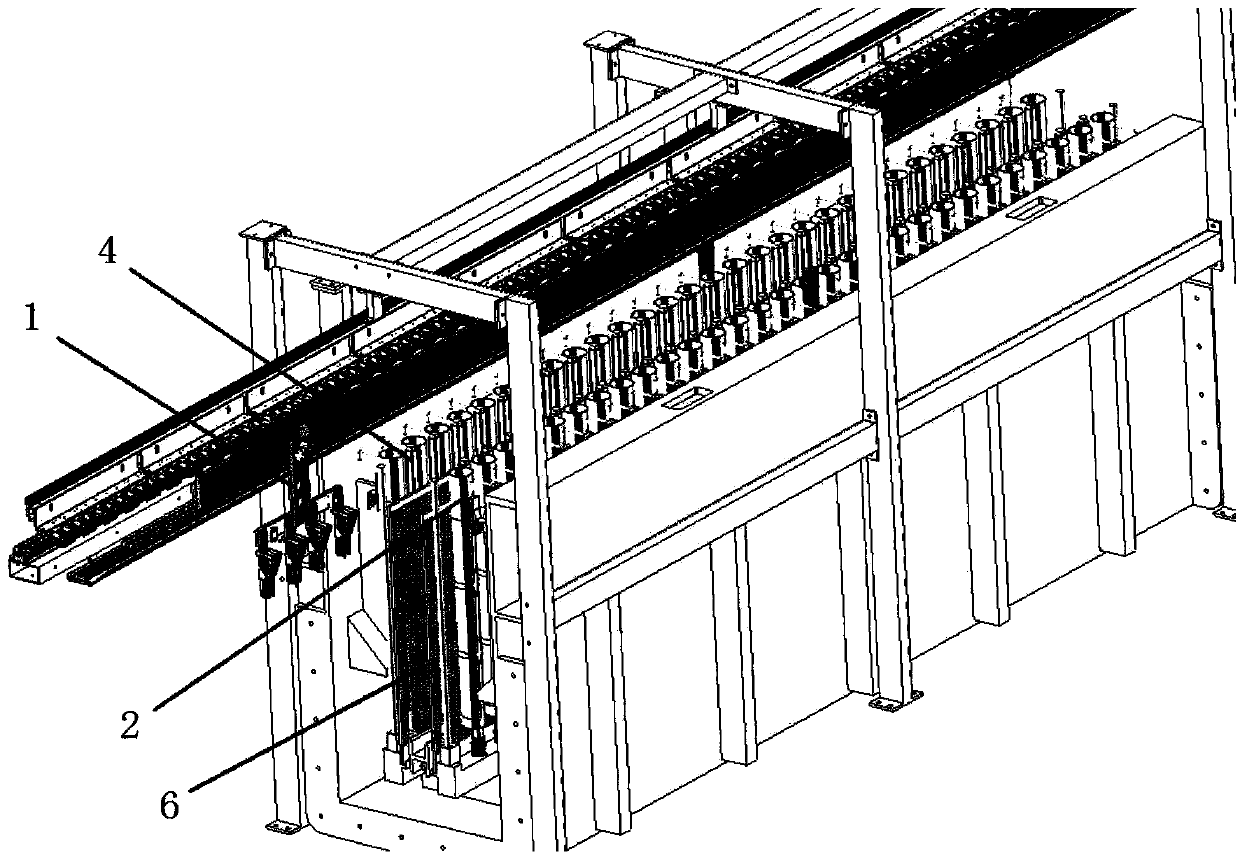

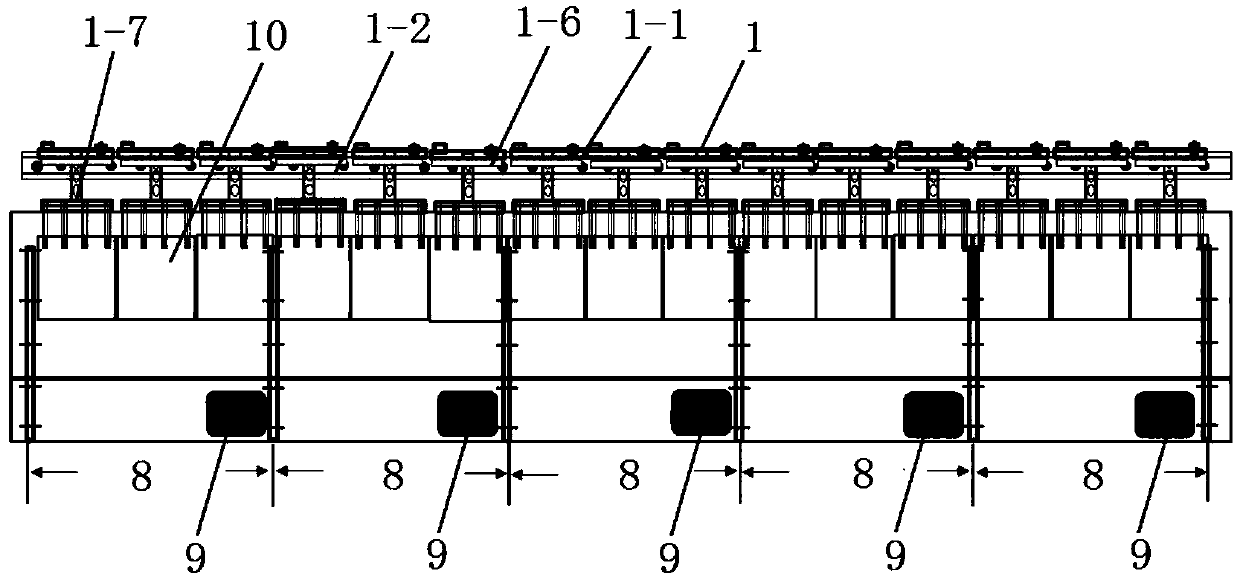

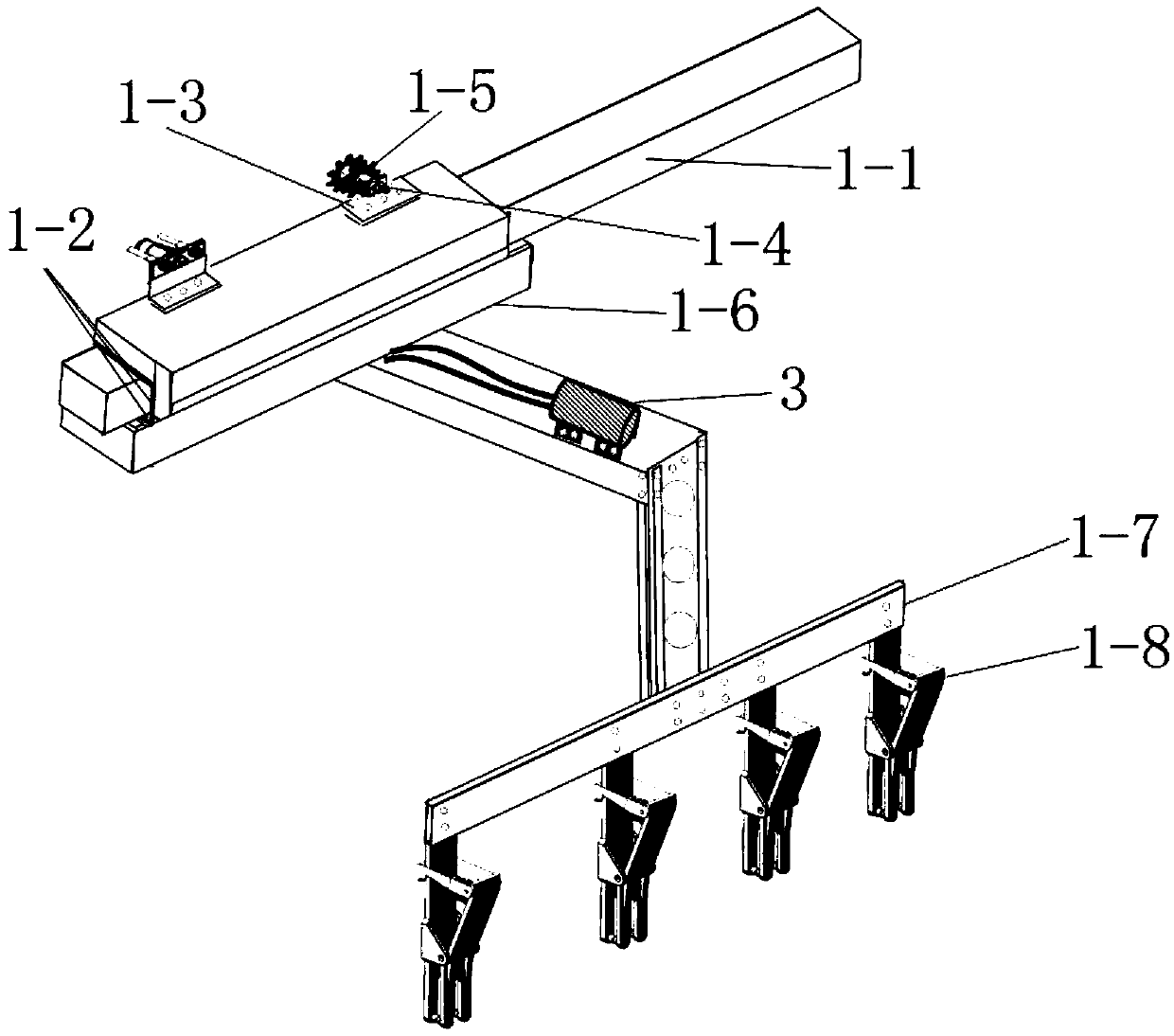

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1-Figure 7 As shown, the electroplating equipment for improving the high-thickness-diameter ratio filling capacity of PCB boards and the uniformity of copper plating in the embodiment of the present invention is composed of a specially designed tank body for anti-inductance, and the core of the tank body design includes (the special method for improving the tank liquid filling capacity) Arranged spray pipes and nozzles, high-uniformity anode power line baffles, jet tubes for lifting bath circulation and stirring, electroplating fixtures equipped with vibration motors), anti-inductance pulse power supplies, anti-inductance cables and other core parts composition;

[0034] Specifically, the present invention includes: a transmission flyer 1, an electroplated titanium basket 2, a vibrating device 3, a nozzle 4, a jet pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com