Coal water slurry and preparation method thereof

A technology of coal water slurry and coal powder, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., and can solve the problem of low concentration of coal water slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

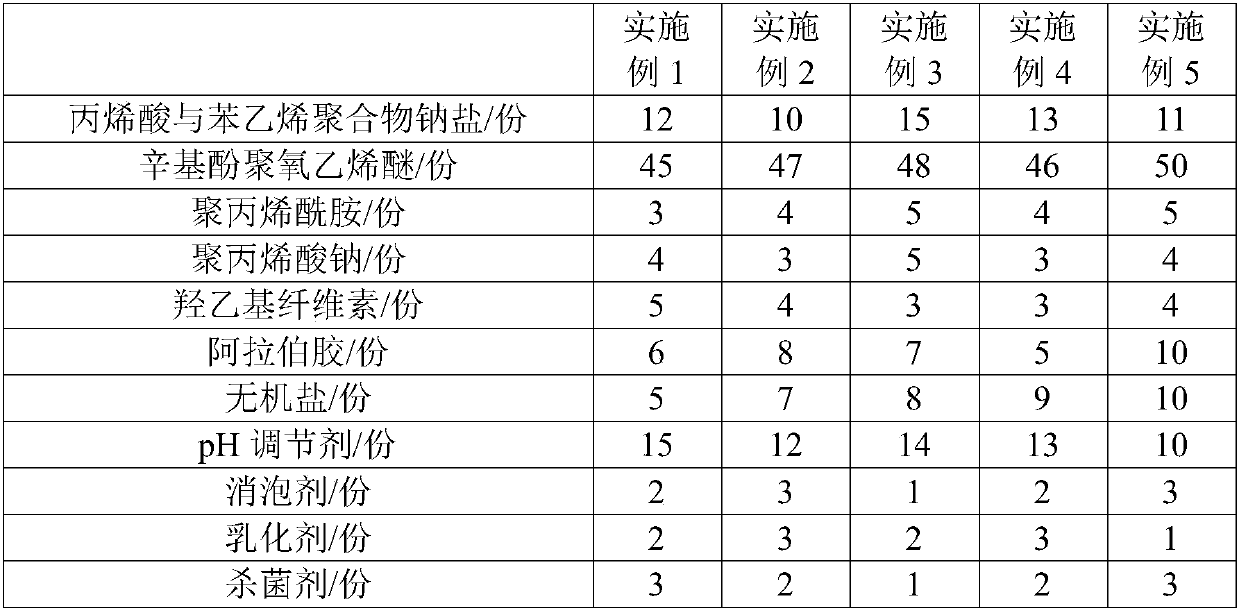

[0045] A preparation method of composite additive, comprising the steps of:

[0046] Step 1: According to parts by weight, weigh sodium salt of acrylic acid and styrene polymer, octylphenol polyoxyethylene ether, polyacrylamide, sodium polyacrylate, hydroxyethyl cellulose, gum arabic, inorganic salt, pH regulator, Defoamer, emulsifier, bactericide;

[0047] Step 2: Mix all components evenly.

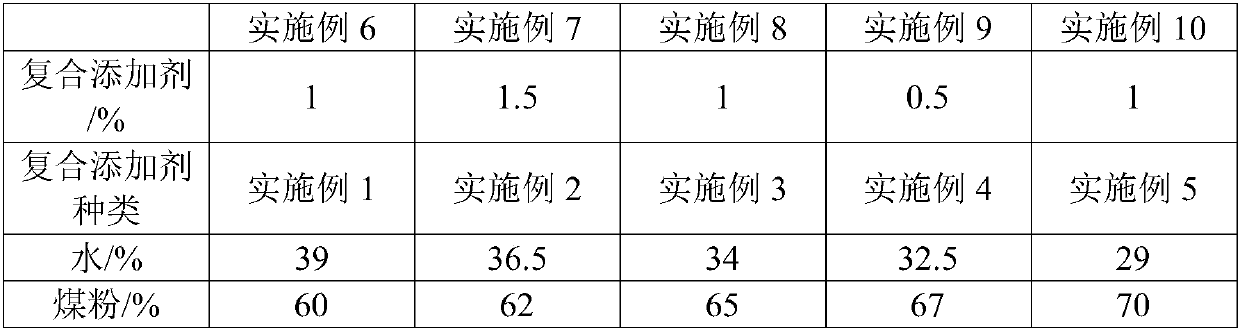

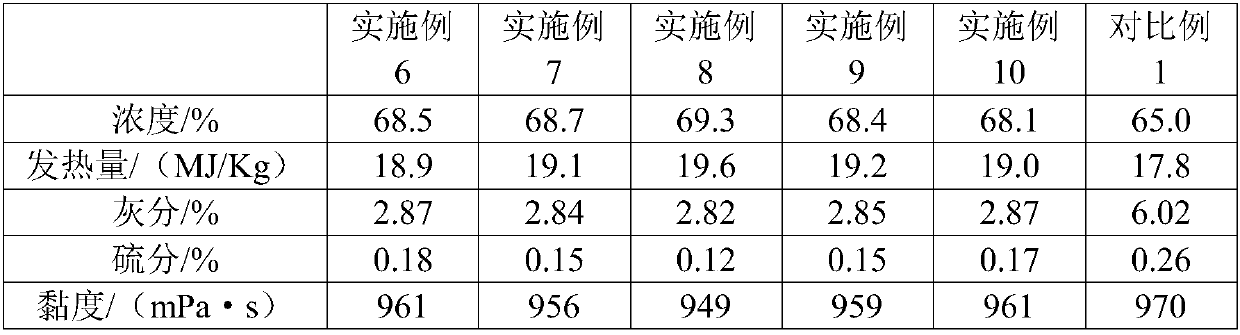

[0048] Examples 6-10 are used to illustrate the components of coal water slurry. The components of embodiment 6-10 coal water slurry are shown in Table 2.

[0049] The component table of table 2, embodiment 6-10 coal-water slurry

[0050]

[0051] Note: % refers to mass fraction;

[0052] Coal powder is obtained by grinding Shenhua coal; the parameters of Shenhua coal are as follows: M ad 10.5wt%, A d 6.79wt%, V daf 35.42wt%, FC ad 53.37wt%, C ad 66.76wt%, H ad 3.48wt%, N ad 0.86wt%, S t,ad 0.37wt%, Q b,ad 26.42MJ / Kg. The particle size of coal powder is 88.64 μm.

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com