Preparation process of environment-friendly durable building material

A technology of building materials and preparation technology, which is applied in the field of building materials, can solve the problems of insufficient impermeability and frost resistance of building materials, achieve the effect of tight structure, stable structure, and improved impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An environmentally friendly and durable building material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of Portland cement, 30 parts of pozzolan, 300 parts of sand, 5 parts of aggregate, 10 parts of antifreeze, 15 parts of xanthan gum, 2 parts of water reducer, 30 parts of water;

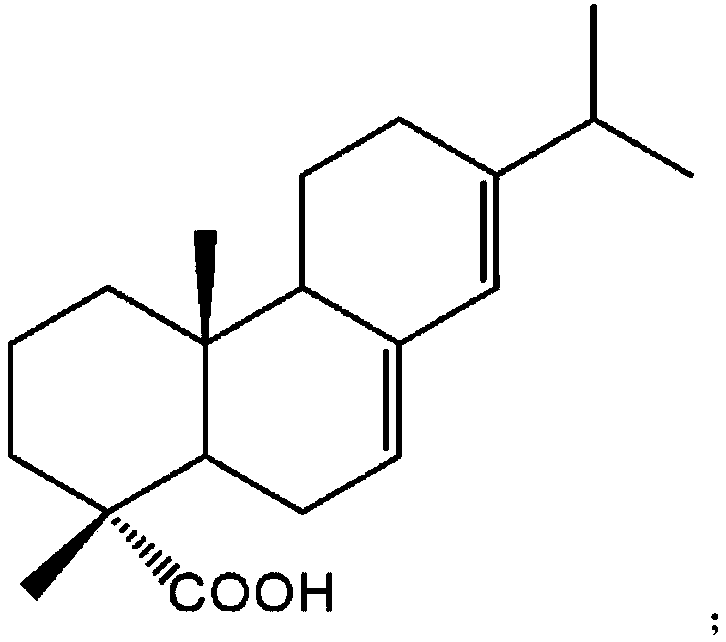

[0027] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0028]

[0029] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0030] Its preparation process comprises the following steps:

[0031] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0032] S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland c...

Embodiment 2

[0035] An environmentally friendly and durable building material proposed by the present invention comprises the following raw materials in parts by weight: 100 parts of Portland cement, 36 parts of pozzolan, 350 parts of sand, 8 parts of aggregate, 13 parts of antifreeze, 18 parts of xanthan gum, 3 parts of water reducer, 40 parts of water;

[0036] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0037]

[0038] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0039] Its preparation process comprises the following steps:

[0040] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0041]S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland ce...

Embodiment 3

[0044] An environmentally friendly and durable building material proposed by the present invention includes the following raw materials in parts by weight: 100 parts of Portland cement, 40 parts of pozzolan, 400 parts of sand, 10 parts of aggregate, 15 parts of antifreeze, 20 parts of xanthan gum, 4 parts of water reducer, 50 parts of water;

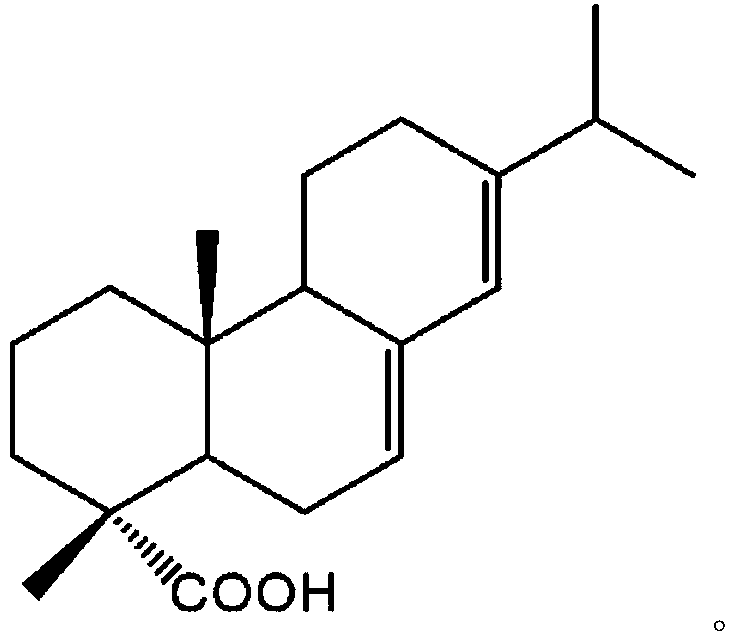

[0045] Described antifreeze is made of antifreeze component A and sodium nitrite, wherein, the mass ratio of antifreeze component A and sodium nitrite in antifreeze is 1:3, and the structural formula of antifreeze component A is as follows:

[0046]

[0047] The mass ratio of the volcanic ash to the xanthan gum is 2:1.

[0048] Its preparation process comprises the following steps:

[0049] S1. Preparation of antifreeze: mix antifreeze component A and sodium nitrite in proportion, and mechanically stir until uniform to obtain antifreeze;

[0050] S2. Prepare raw materials: Weigh each raw material according to 100 parts of Portland c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com