Fiber band toughened sandwich structure of honeycomb core body

A sandwich structure, honeycomb core technology, applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problems of debonding of the surface-core interface and small contact area of the surface-core interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

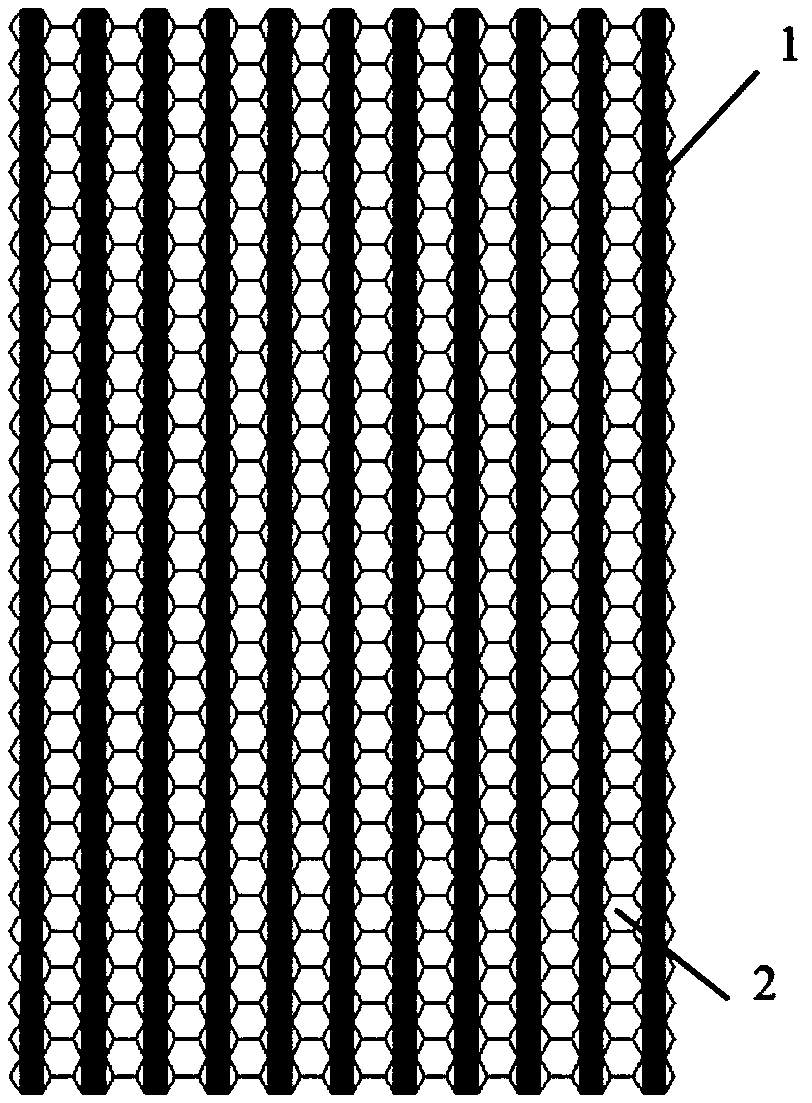

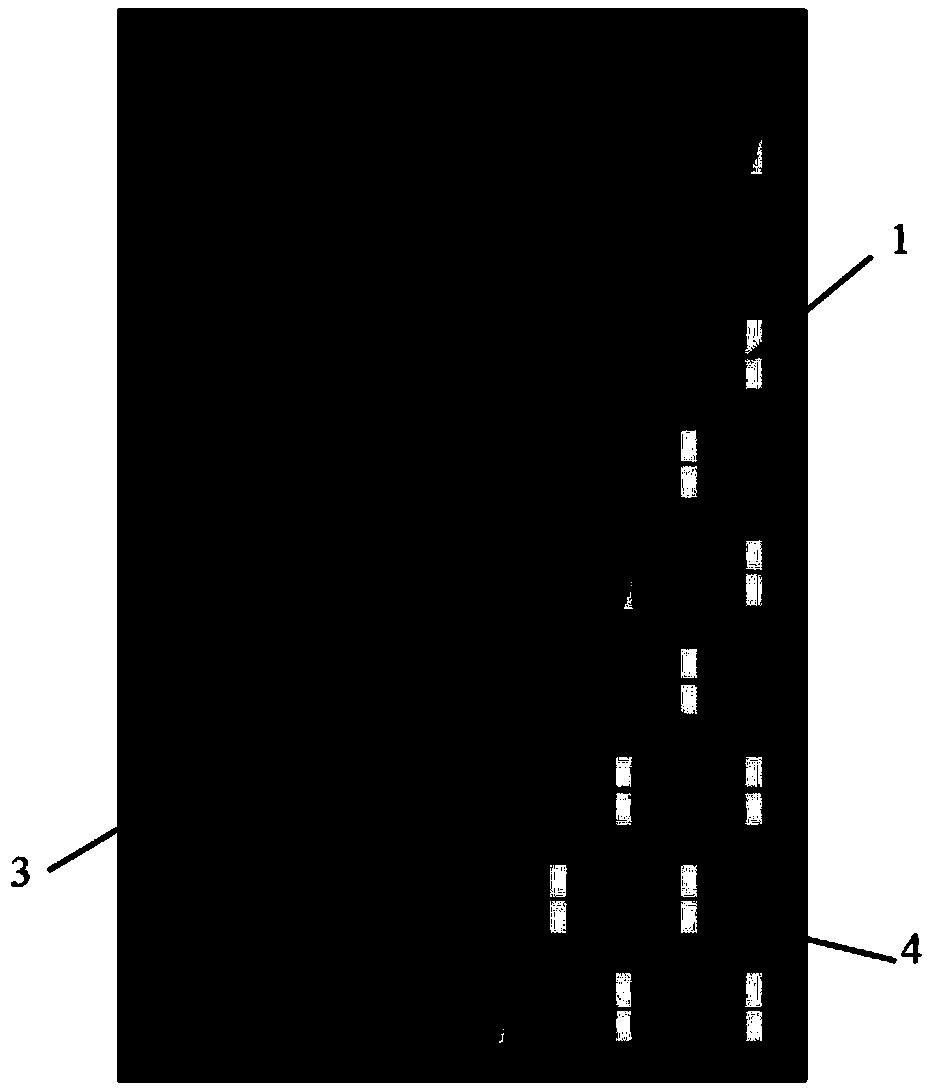

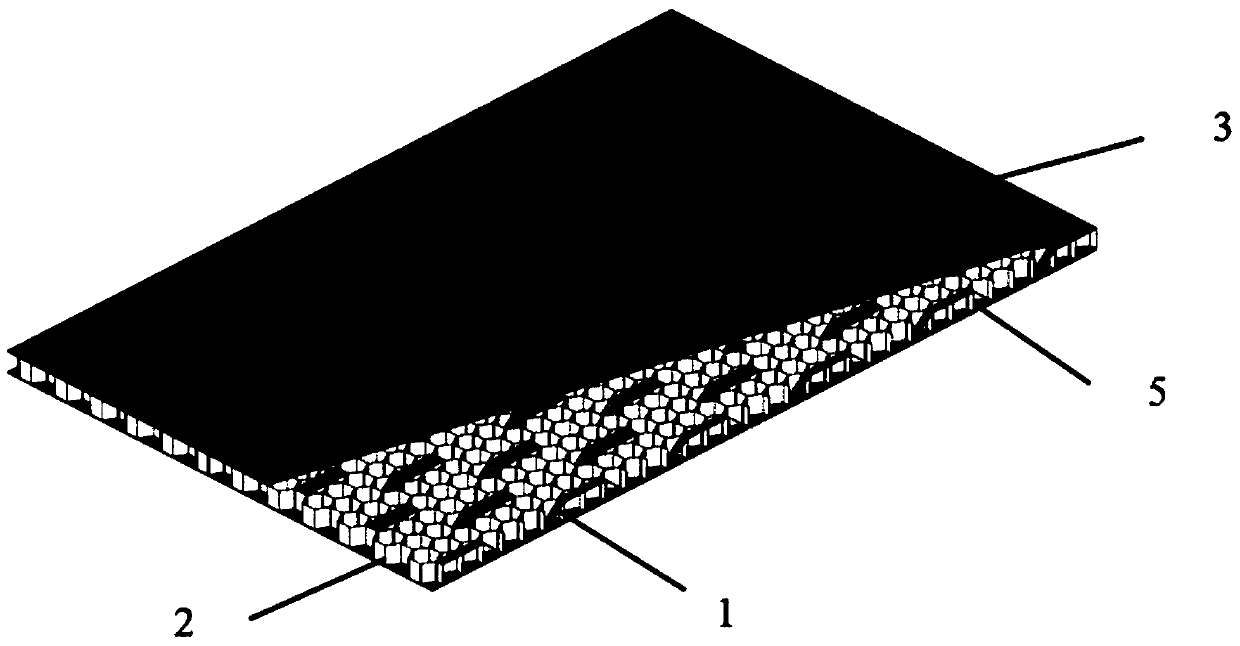

[0034] Specific example 1: Sandwich panel with carbon fiber tape toughened aluminum honeycomb, its upper and lower skins are made of 6 layers of unidirectional carbon fiber cloth and LY5288 / HY5289 epoxy resin, wherein the 6 layers of carbon fiber cloth are all orthogonal Laying, the skin height (thickness) is 1.2mm; the aluminum honeycomb aperture is 6mm, the hole wall thickness is 0.06mm, and the height is 10mm; the toughening fiber tape is formed by shearing unidirectional carbon fiber prepreg along the fiber direction, and the width of the carbon fiber tape is about 3mm ;Aramid staple fiber film is made of Kevlar49, with an area density of 12g / m 2 , The short fiber length is about 10mm.

[0035] In a Z-shaped unit in which carbon fiber strips are interspersed with aluminum honeycomb cores, the fiber strips cover two honeycomb units on the surface of a core, and the distance between the two fiber strips is one honeycomb unit cell, such as Figure 4 shown.

[0036] The afor...

specific Embodiment 2

[0043] Specific embodiment 2: have the sandwich panel of carbon fiber band toughened aluminum honeycomb, in a Z-shaped unit that carbon fiber band penetrates aluminum honeycomb core body, fiber band covers three honeycomb unit cells on a core body surface, two fiber bands The distance is one honeycomb unit cell. The sandwich panel preparation process and sample size are the same as in Example 1, and the displacement loading rate of the three-point bending test is 2mm / min.

[0044] Figure 8 The load-displacement curves of sandwich beams with or without fiber tape-toughened aluminum honeycomb core are given when the displacement loading rate is 2mm / min, in which the fiber tape-toughened aluminum honeycomb Both the toughened sandwich beam and the non-toughened sandwich beam have 4 samples participating in the test. It can be seen from the figure that the load-displacement curve of the sample toughened with fiber tape is basically above the load-displacement curve of the untoug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Areal density | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com