Auxiliary agent for straw artificial board and preparation method for straw artificial board

A wood-based panel and straw technology, applied in the field of panel manufacturing technology, can solve the problems of high cost, complicated operation process, and difficult industrialization, etc., and achieve the effects of improving elastic modulus, wide source of raw materials, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

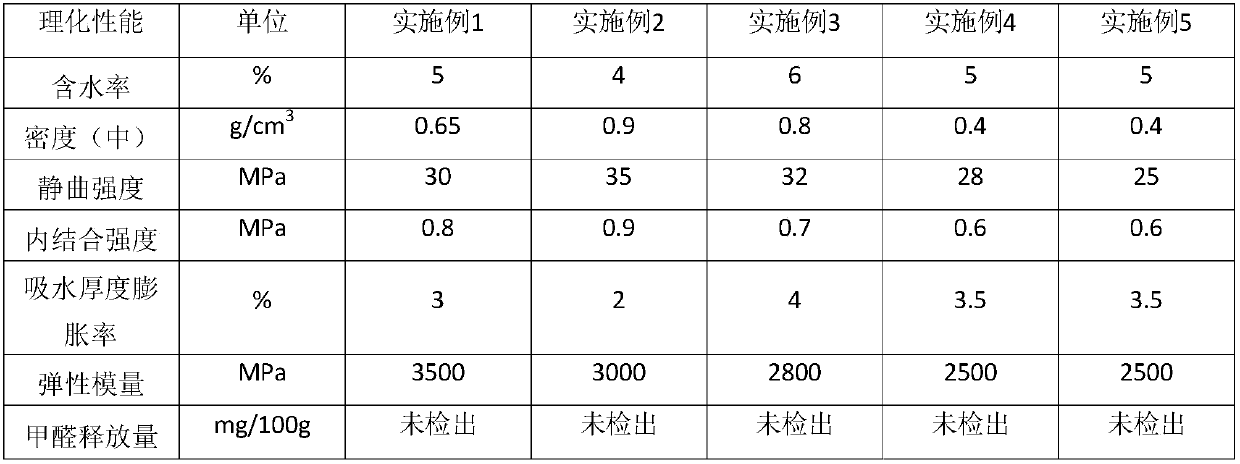

Examples

Example Embodiment

[0037] Example 1

[0038] 1. Preparation of natural auxiliaries for corn stalk wood-based panels:

[0039] 10 parts Mg(OH) 2 , 5 parts CaSO 4 , 1.5 parts of methylparaben, and 3 parts of polypropylene are mixed and stirred evenly to obtain straw additives, which are convenient for later batching.

[0040] 2. Preparation of corn stover wood-based panels:

[0041] (1) 80.5 parts of corn stalks with a moisture content of 12% are sent to a pulverizer for pulverization by a screw conveyor, and the length of the pulverized material is 0.5cm; and then kneaded by a silk kneading machine, and then sent to a cyclone dust collector through a conveyor belt after kneading. The soil, gravel and impurities are removed in the middle, and sent to a dryer through a blower to dry to a moisture content of less than 8%.

[0042] (2) Mixing ingredients and paving: After drying, the corn stalk enters the batching tank and is mixed with the pre-prepared additives; after mixing, it is sent to the ...

Example Embodiment

[0050] Example 2

[0051] 1. Preparation of natural auxiliaries for cotton straw wood-based panels:

[0052] 7 parts Mg(OH) 2 , 10 parts CaSO 4 , 5.5 parts of phenol and 2 parts of polyethylene are mixed and stirred evenly to obtain straw additives, which is convenient for later batching.

[0053] 2. Preparation of cotton straw wood-based panels:

[0054] (1) 75.5 parts of cotton stalks with a moisture content of 13% are sent to the pulverizer for pulverization by a screw conveyor, and the length of the pulverized material is 1.5cm; and then kneaded by a silk kneading machine, and then sent to a cyclone dust collector through a conveyor belt after kneading. The soil, gravel and impurities are removed in the middle, and sent to a dryer through a blower to dry to a moisture content of less than 9%.

[0055] (2) Mixing ingredients and paving: After drying, the cotton straw enters the batching tank and mixes with the pre-prepared additives; after mixing evenly, it is sent to t...

Example Embodiment

[0063] Example 3

[0064] 1. Preparation of natural additives for peanut straw wood-based panels:

[0065] 6 parts Mg(OH) 2 , 17 parts of CaSO 4 , 6 parts of methyl parahydroxybenzoate, and 3 parts of polyethylene are mixed and stirred evenly to obtain straw auxiliary, which is convenient for later batching.

[0066] 2. Preparation of peanut straw wood-based panels:

[0067] (1) Send 68 parts of peanut straw with a moisture content of 14% to the pulverizer for pulverization with a screw conveyor, and the length of the pulverized material is 2cm; and then knead the silk by the silk rolling machine, and then send the silk to the cyclone dust collector through the conveyor belt. The soil, gravel and impurities are removed, and sent to a dryer through a blower to dry to a moisture content of less than 8%.

[0068] (2) Mixing ingredients and paving: After drying, the peanut straw enters the batching tank and mixes with the pre-prepared additives; after mixing evenly, it is sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com