Child-mother sliding table device for rapid response for piston machining

A fast-response, sliding table technology, applied in the direction of positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of complex overall structure, inability to realize high-frequency reciprocating and large-stroke feeding of the sliding table at the same time, and achieve machine tool motion accuracy High, easy-to-precise control, and fast-response effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

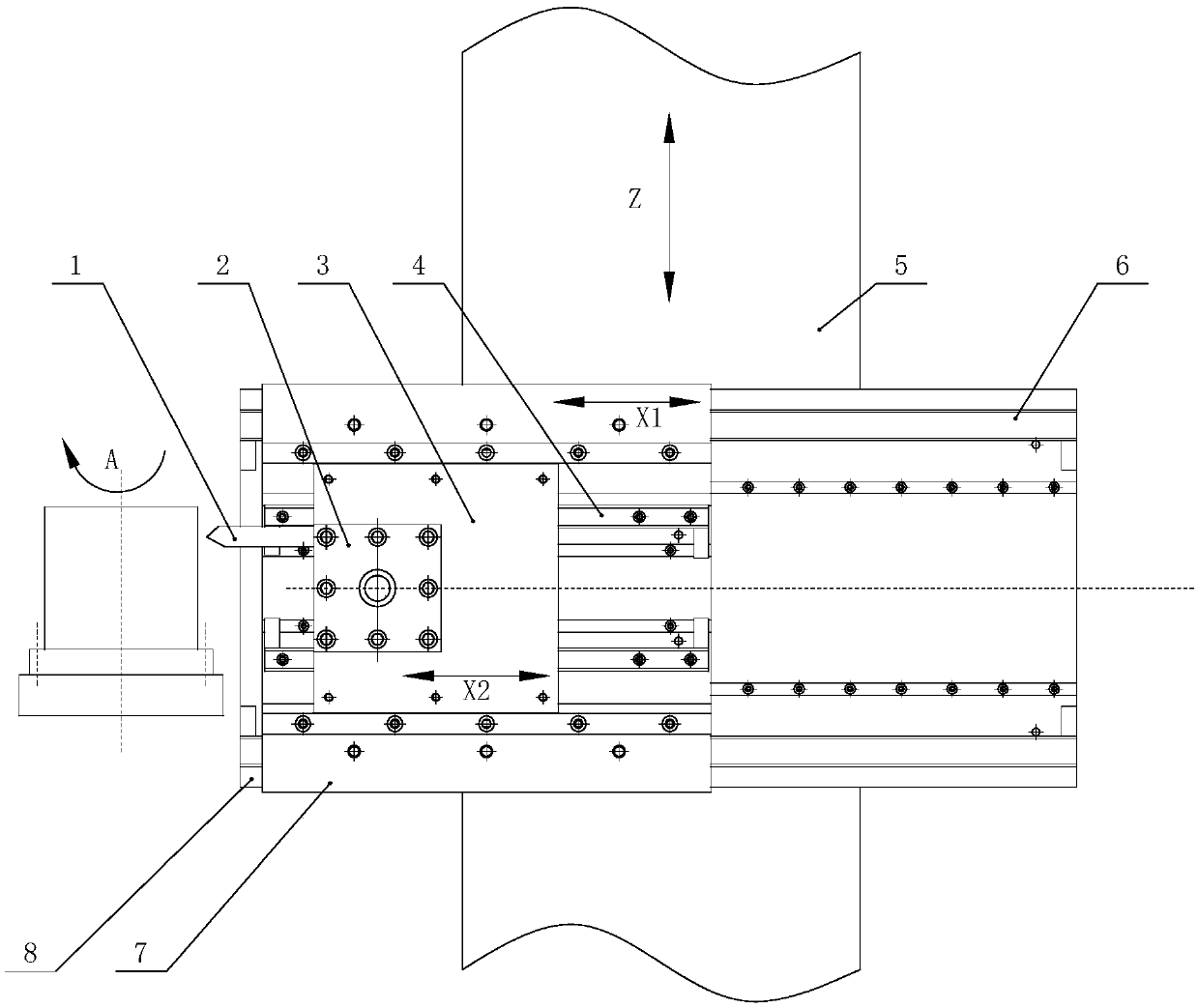

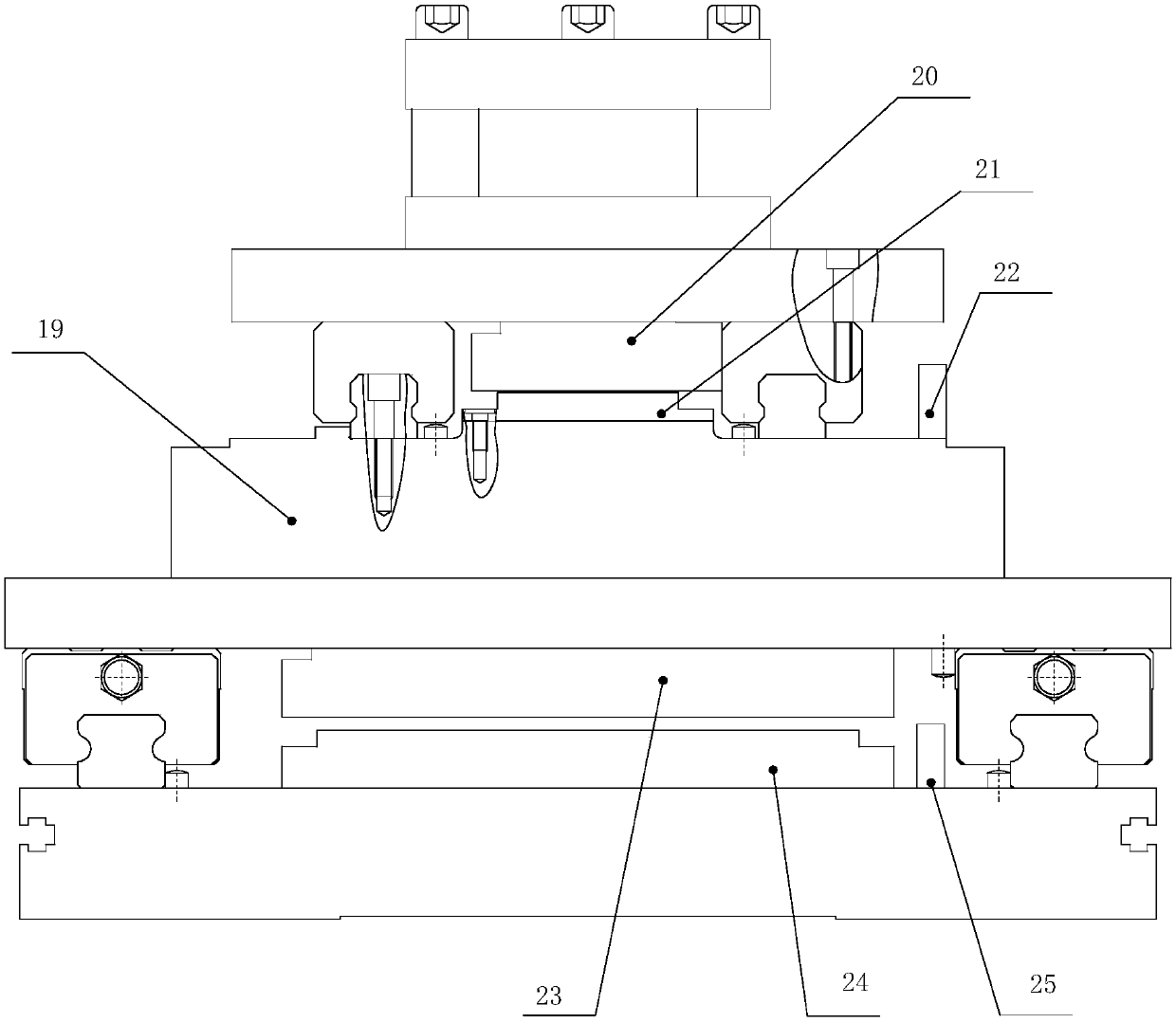

[0030] refer to Figure 1 to Figure 3 As shown, this preferred embodiment provides a quick-response master slide device for piston processing. The master slide device is set on the machine tool for processing convex and non-circular pistons, specifically including vertical installation on the machine tool The Z-axis feed system 5 on the top, the parent slide X1 system and the child slide X2 system vertically arranged with the Z-axis feed system 5.

[0031] The sub-slider X2 system in this preferred embodiment is set on the parent slider X1 system and can move back and forth at high frequency relative to the parent slider X1 system. The main shaft of the machine tool is provided with a fixture for clamping the workpiece and making it axially To lock, the workpiece is provided with a positioning notch, which is used to cooperate with the fixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com