Machining process of hollow stepped shaft

A processing technology and a step shaft technology, which is applied to the processing technology field of a hollow step shaft, can solve the problems of low production efficiency and high raw material cost, and achieve the effects of low production cost, high raw material utilization rate and good mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In order to solve the problem of cold heading forming of a hollow stepped shaft, the present invention adopts five-die and five-blow forming equipment, and realizes cold heading forming of five-stage stepped shafts through five-station continuous forming.

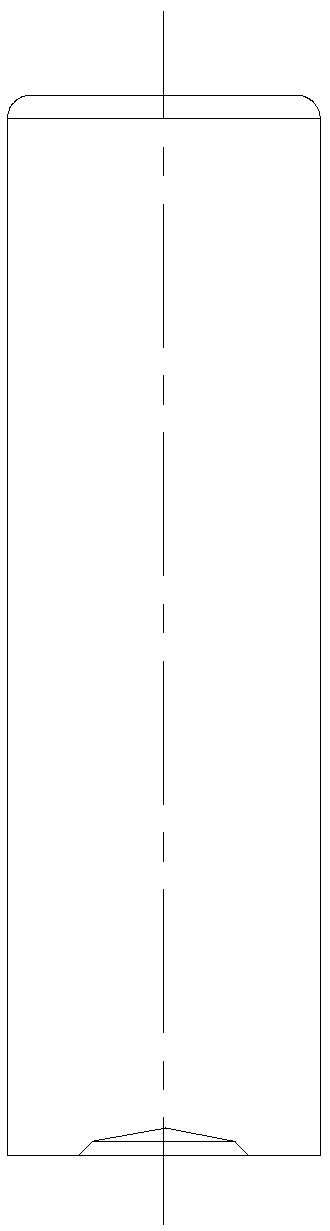

[0038] as attached Figure 1a Shown is the first step of cutting the blank by the cold heading machine: the continuous cold heading wires are cut off one by one by plastic shear deformation, and the cutting length is converted by the principle of part volume conservation. The molds used include a wire mold and a shear mold. The contact surface of the center holes of the two molds is used as the cutting edge. Diameter +0.10mm.

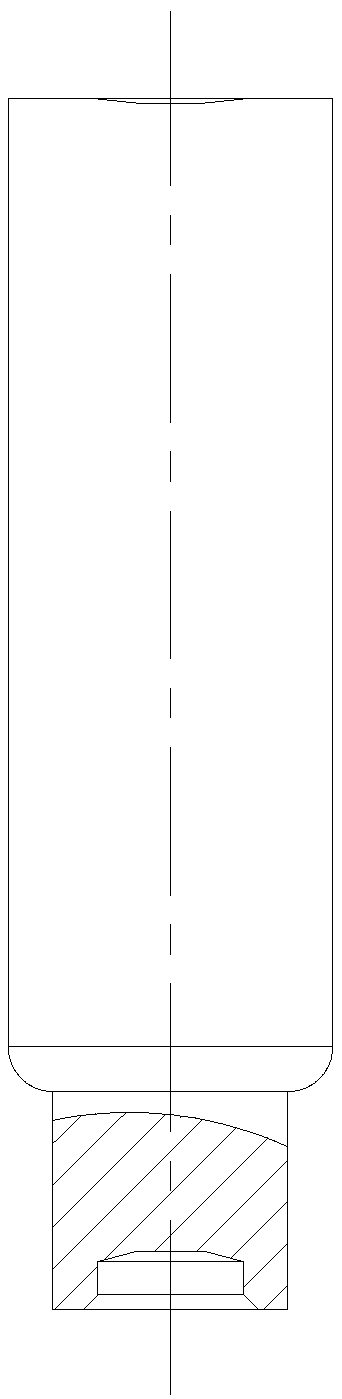

[0039] as attached Figure 1b Shown is the blank in the second step of end face shaping and blank pre-positioning hole forming station, the shaping die in the forming process, the upper part of the blank is wrapped in the die to shape the upper end face, the purpose is to ensure the flatness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com