Combined landfill site closure system

A landfill and combined technology, applied in the direction of landfill technology, solid waste removal, etc., can solve the problems of landfill volume reduction, groundwater pollution, waste of resources, etc., to increase the amount of waste The effect of landfill volume, resource saving and height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

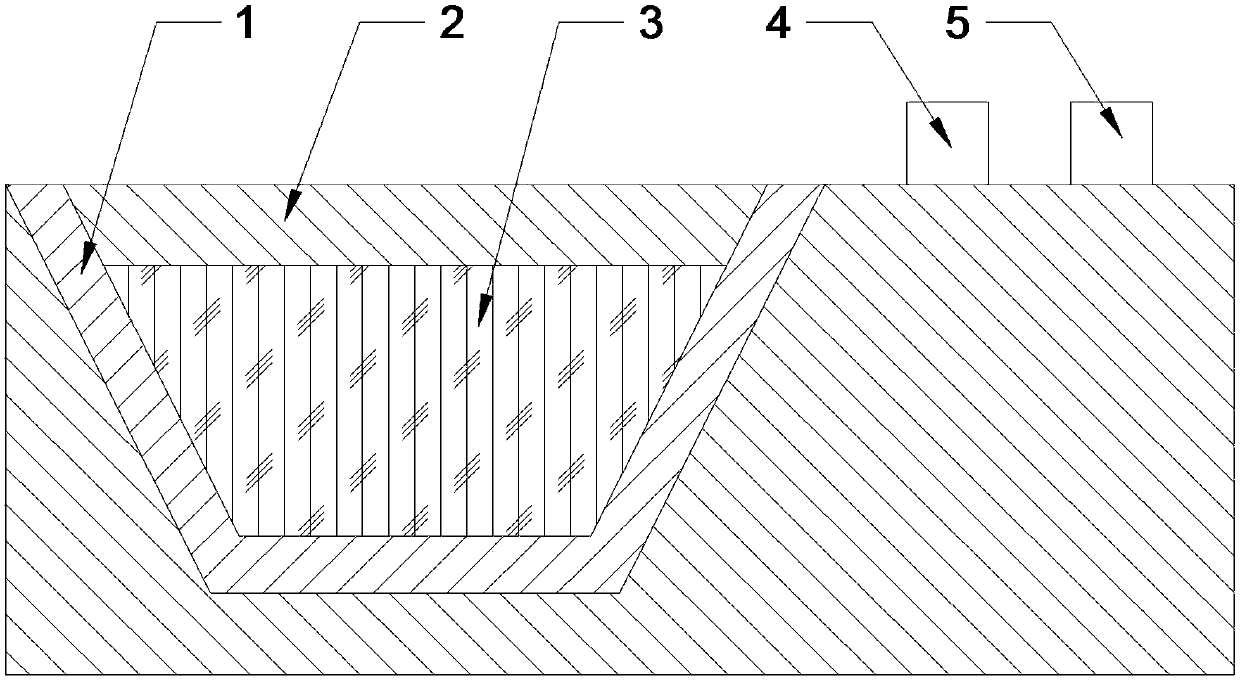

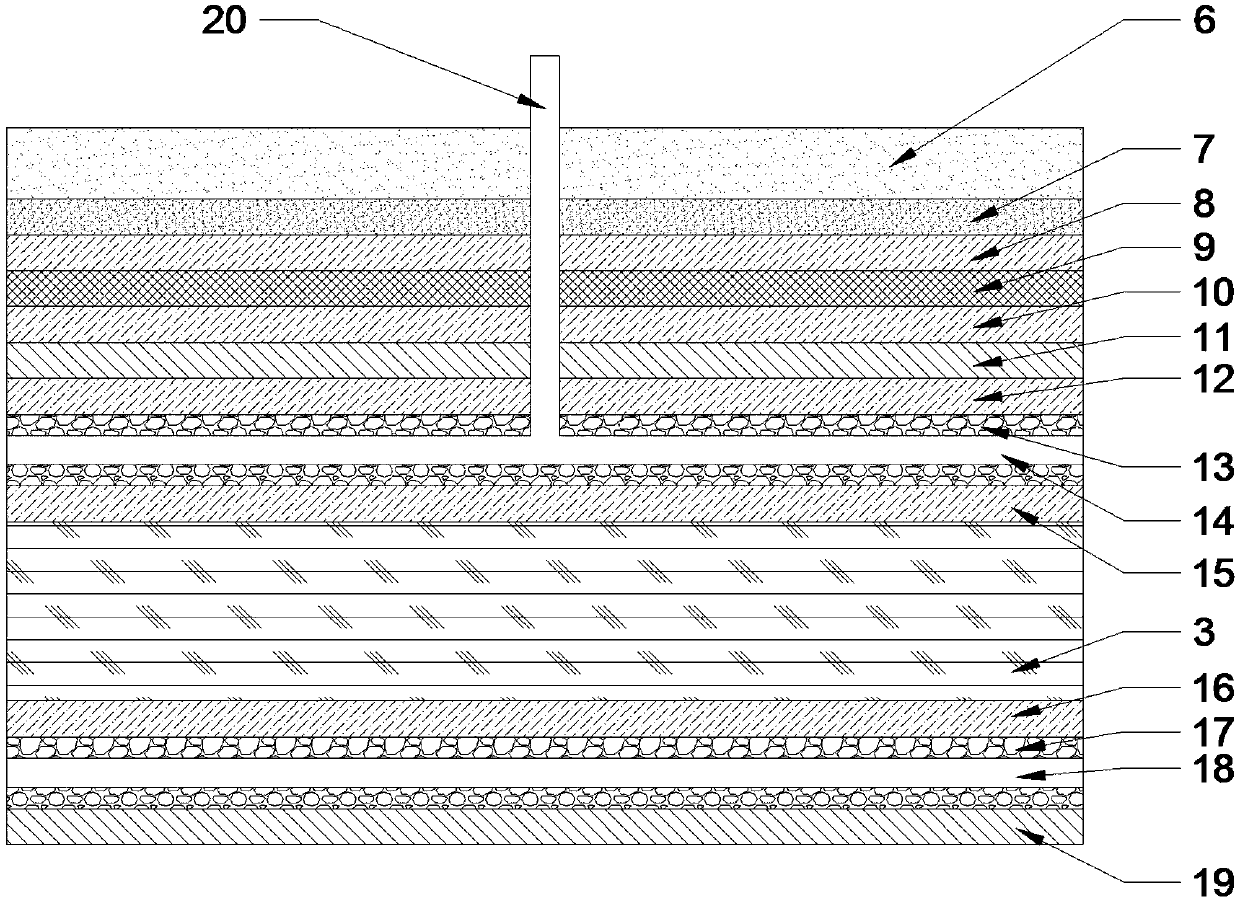

[0033] see Figure 1~4 , a combined landfill closure system, comprising a landfill body, the bottom and sides of the landfill body are provided with an anti-seepage layer 1, and a drainage pipeline 18 is laid in the anti-seepage layer 1, and the drainage pipe The road 18 is connected with the sewage treatment station 4; the inner cavity of the landfill body is filled with solid waste 3, and the top of the solid waste 3 is provided with a covering layer 2, which is successively composed of gravel layer-13, geomembrane-11 from bottom to top. , drainage net 9, vegetation layer 6;

[0034] In this example, before the waste is stored in the landfill, an anti-seepage layer 1 is constructed on the bottom and sides of the landfill body to prevent the leachate generated by the solid waste 3 from seeping into the ground after the landfill is closed and polluting groundwater sources. When the garbage is piled up on the landfill body, a compaction operation is performed every time a cert...

Embodiment 2

[0036] see Figure 1~4 , a combined landfill closure system, comprising a landfill body, the bottom and sides of the landfill body are provided with an anti-seepage layer 1, and a drainage pipeline 18 is laid in the anti-seepage layer 1, and the drainage pipe The road 18 is connected with the sewage treatment station 4; the inner cavity of the landfill body is filled with solid waste 3, and the top of the solid waste 3 is provided with a covering layer 2, which is successively composed of gravel layer-13, geomembrane-11 from bottom to top. , drainage net 9, vegetation layer 6;

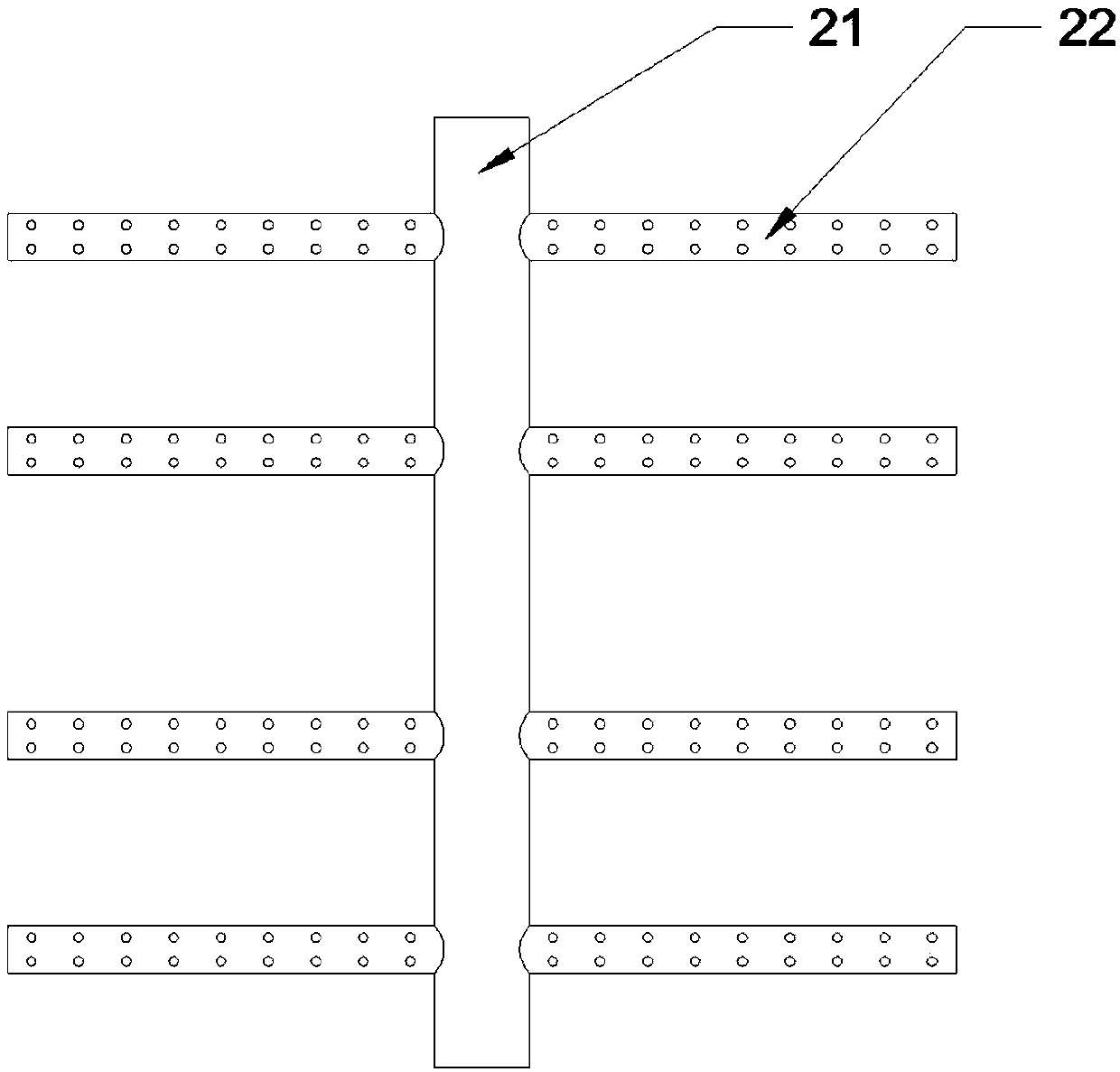

[0037] In this example, the drainage pipeline 18 includes a water collection pipe 21 , and a plurality of water collection flower pipes 22 are distributed on both sides of the water collection pipe 21 in a fishbone shape. The water collection pipe 21 is connected to the sewage treatment station 4 . By setting the drainage pipeline 18, the leachate produced by the degradation of the solid waste 3 can b...

Embodiment 3

[0040] see Figure 1~4 , a combined landfill closure system, comprising a landfill body, the bottom and sides of the landfill body are provided with an anti-seepage layer 1, and a drainage pipeline 18 is laid in the anti-seepage layer 1, and the drainage pipe The road 18 is connected with the sewage treatment station 4; the inner cavity of the landfill body is filled with solid waste 3, and the top of the solid waste 3 is provided with a covering layer 2, which is successively composed of gravel layer-13, geomembrane-11 from bottom to top. , drainage net 9, vegetation layer 6;

[0041] In this example, the exhaust pipeline 14 includes an air collecting pipe 23, and the two sides of the air collecting pipe 23 are distributed in a fishbone shape with a plurality of air collecting flower tubes 24, and the upper surface of the air collecting pipe 23 is provided with an exhaust pipe 20, and the exhaust pipe 20 Extending through the cover layer 2 to the ground, the exhaust pipe 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com