Aerobic fermentation waste gas biotreatment method

A technology of aerobic fermentation and biological treatment, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as poor treatment effect and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

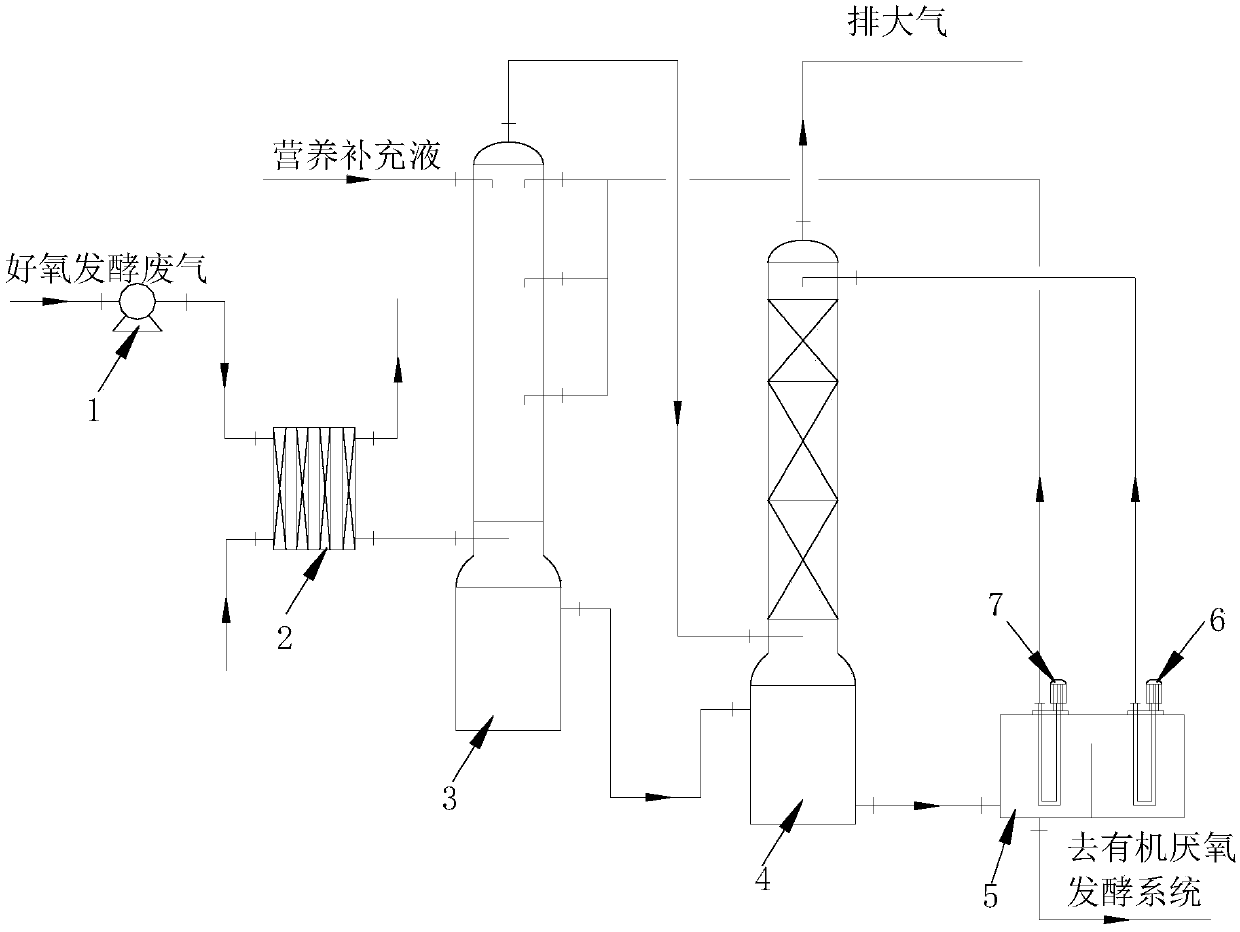

Image

Examples

Embodiment 1

[0028] A biological treatment method for aerobic fermentation waste gas, comprising the following steps:

[0029] (a) Cooling and cooling: the aerobic fermentation waste gas from the aerobic fermentation tank is pressurized by a fan, the pressure of the cooling tower is controlled to be 5-10KPa, and the temperature drops to 45°C after entering the air heat exchanger for heat exchange, and then Pass into the cooling tower and use spray liquid for spray cooling, the exhaust gas flow rate is 1.5-2m / s, and the waste gas stays in the cooling tower for 4-6s; the gas-liquid volume ratio in the cooling tower is 25:1; after cooling The temperature of the aerobic fermentation waste gas is 25-30°C, and the liquid obtained after spraying is transported to the biological deodorization tower; the spray liquid is biogas slurry produced by aerobic fermentation, and the liquid level of the cooling tower is controlled to be 1 / 2-2 / 3 liquid level height.

[0030] (b) Biological deodorization: t...

Embodiment 2

[0033] A biological treatment method for aerobic fermentation waste gas, comprising the following steps:

[0034] (a) Cooling and cooling: the aerobic fermentation waste gas from the aerobic fermentation tank is pressurized by a fan, the pressure of the cooling tower is controlled to be 5-10KPa, and the temperature drops to 40°C after being passed into the air heat exchanger for heat exchange, and then Pass into the cooling tower and use spray liquid for spray cooling, the exhaust gas flow rate is 1.5-2m / s, and the waste gas stays in the cooling tower for 4-6s; the gas-liquid volume ratio in the cooling tower is 30:1; after cooling The temperature of the aerobic fermentation waste gas is 25-30°C, and the liquid obtained after spraying is transported to the biological deodorization tower; the spray liquid is organic waste liquid produced after anaerobic fermentation, and the liquid level of the cooling tower is controlled It is 1 / 2-2 / 3 liquid level height.

[0035](b) Biologic...

Embodiment 3

[0038] A biological treatment method for aerobic fermentation waste gas, comprising the following steps:

[0039] (a) Cooling and cooling: the aerobic fermentation waste gas from the aerobic fermentation tank is pressurized by a fan, the pressure of the cooling tower is controlled to be 5-10KPa, and the temperature drops to 42°C after being passed into the air heat exchanger for heat exchange, and then Pass into the cooling tower and use spray liquid for spray cooling, the exhaust gas flow rate is 1.5-2m / s, and the time for the exhaust gas to stay in the cooling tower is 4-6s; the gas-liquid volume ratio in the cooling tower is 27:1; after cooling The temperature of the aerobic fermentation waste gas is 25-30°C, and the liquid obtained after spraying is transported to the biological deodorization tower; the spray liquid is organic waste liquid produced after anaerobic fermentation, and the liquid level of the cooling tower is controlled It is 1 / 2-2 / 3 liquid level height.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com