Method for massively purifying trimethylaluminum crude product

A crude trimethylaluminum and trimethylaluminum technology, applied in the field of microelectronic materials, can solve the problems of uneven rectification column, difficult to amplify production, small working flow rate of microchannel rectification column, etc., and achieve optimized uniformity, The effect of broad practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for large-scale purification of trimethylaluminum crude product, comprising the following steps:

[0028] (1) The microchannel rectification tower is exchanged with inert gas, and the crude product of trimethylaluminum (the purity of trimethylaluminum is 99.93%) is transferred to the rectification kettle;

[0029] (2) After the materials have been transferred, close the feed valve and carry out rectification. Rectification pressure: 0.02MPa, rectification temperature: 80-128°C.

[0030] (3) intercept the distilled material with a boiling point of 125-127°C under standard atmospheric pressure, and collect it with a condenser to obtain a high-purity trimethylaluminum product;

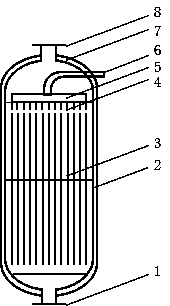

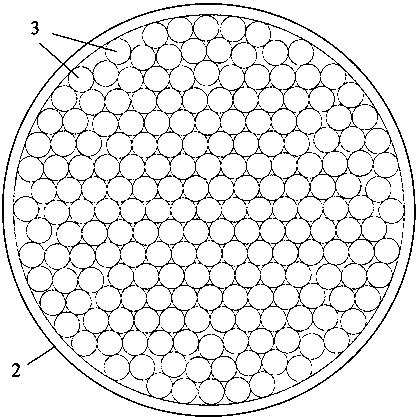

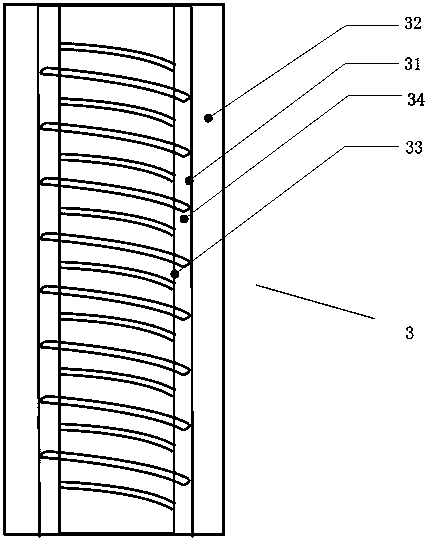

[0031] like Figure 1~3 As shown, in the microchannel rectification tower 2, several microchannel rectification columns 3 are fixed into a rectification column bundle through a cluster device, and the microchannel rectification tower is provided with a heating jacket for heating and steam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com