Rigidity-adjustable orthopedic insole and 4D printing forming method thereof

A molding method and adjustable technology, applied in the field of orthopedic insoles, can solve problems such as unfavorable foot orthopedics, complicated manufacturing process, and increased foot load, and achieve the effects of saving materials and energy, simple and light structure, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the technical method of the present invention is not limited to the specific implementation methods listed below.

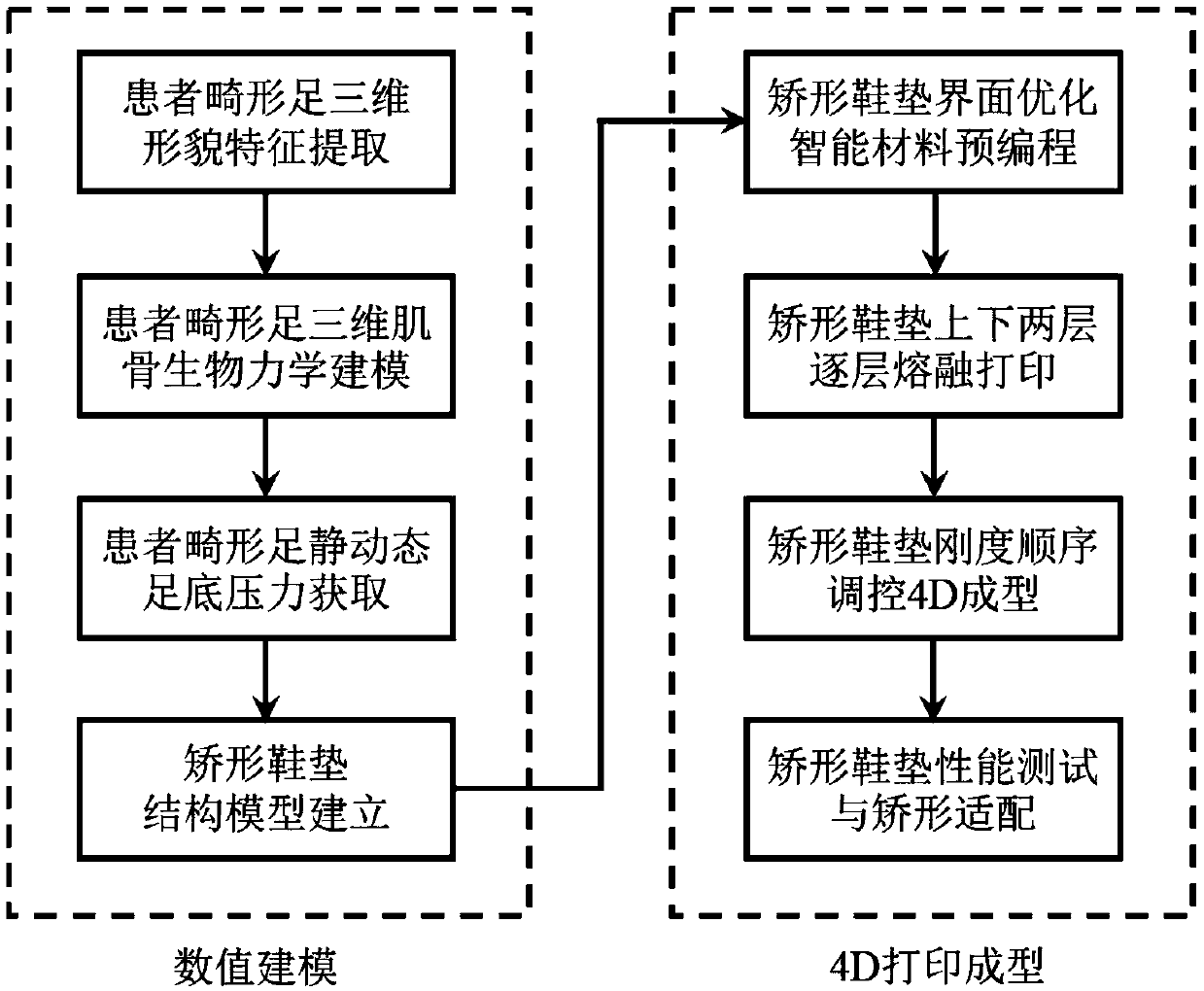

[0039] Such as figure 1 As shown, a method for 4D printing of orthopedic insoles with adjustable stiffness disclosed in the present invention comprises the following steps:

[0040] 1) Using the three-dimensional optical scanning system of the human foot to obtain the three-dimensional shape characteristic data of the patient's foot, and establish the three-dimensional point cloud model of the patient's foot;

[0041] 2) Using nuclear magnetic resonance imaging technology, scan and obtain the image data of the clubfoot of the patient in the standing position, and use MIMICS medical software to establish a three-dimensional biomechanical model of the clubfoot of the patient including muscles, ligaments and bones;

[0042] 3) Use the human plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com