A speed change structure and a transmission device for rubber tire processing and transfer equipment

A technology of variable speed structure and transmission device, applied in the directions of transportation, packaging, conveyors, etc., can solve the problem of fixed transmission speed, and achieve the effect of improving the scope of application and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

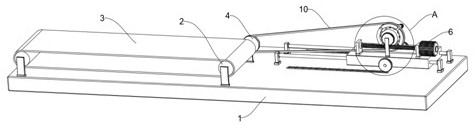

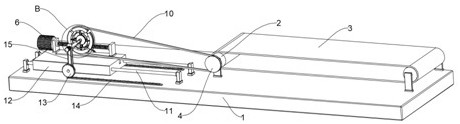

[0029] see Figure 1 to Figure 3 , in the embodiment of the present invention, a speed change structure, the speed change structure includes a base 1, a driving wheel 4 rotatably mounted on the upper part of the base 1, and a rotating cylinder 9 movably arranged above the base 1 through a linear traveling mechanism, Also includes:

[0030] Arc block 5, four arc blocks 5 are provided, and each of the four arc blocks 5 is movably arranged on the outer wall of the rotating cylinder 9 through a set of thread telescoping mechanism, and the arc block 5 The first belt 10 is connected to the drive wheel 4, and the threaded telescopic mechanism is used to drive the arc block 5 to move away from or close to the rotating cylinder 9, so that the arc block 5 The transmission ratio with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com