Hydraulic system for an automatic gearbox of a motor vehicle

A technology for automatic transmissions, hydraulic systems, applied in the direction of fluid pressure actuation system testing, mechanical equipment, elements with teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

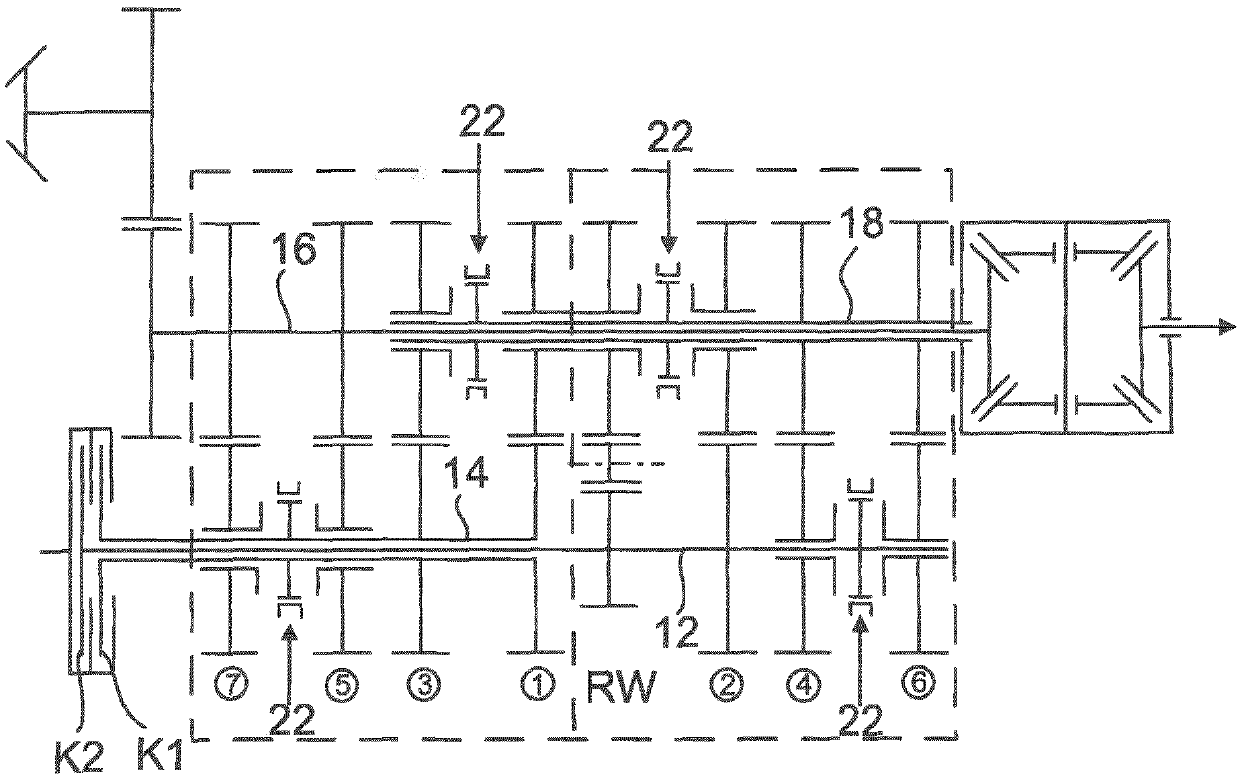

[0028] exist figure 1 A schematic diagram of a dual clutch transmission for a motor vehicle with all-wheel drive is shown in FIG. The dual clutch transmission has seven forward gears (see boxed numbers 1 to 7) and one reverse gear RW. The dual clutch transmission is described below only to the extent necessary to understand the invention. The dual-clutch transmission therefore has two input shafts 12 , 14 which are arranged coaxially with one another and which can be alternately connected to a power source, for example an internal combustion engine, via two hydraulically actuatable multi-plate clutches K1 , K2 . The input shaft 14 is embodied as a hollow shaft, in which the input shaft 12 , which is embodied as a solid shaft, extends. The two input shafts 12 , 14 are driven via gear sets for forward and reverse gears to an output shaft 16 arranged axially parallel and to an intermediate shaft 18 designed as a hollow shaft. The gearsets of the forward gears 1 to 7 each have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com