Method for manufacture of removable dental prosthesis by moulding with the aid of mould formed by additive manufacture

A manufacturing method, additive manufacturing technology, applied in the manufacture of tools, dentures, additive manufacturing, etc., which can solve the problems of heavy, long and boring manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

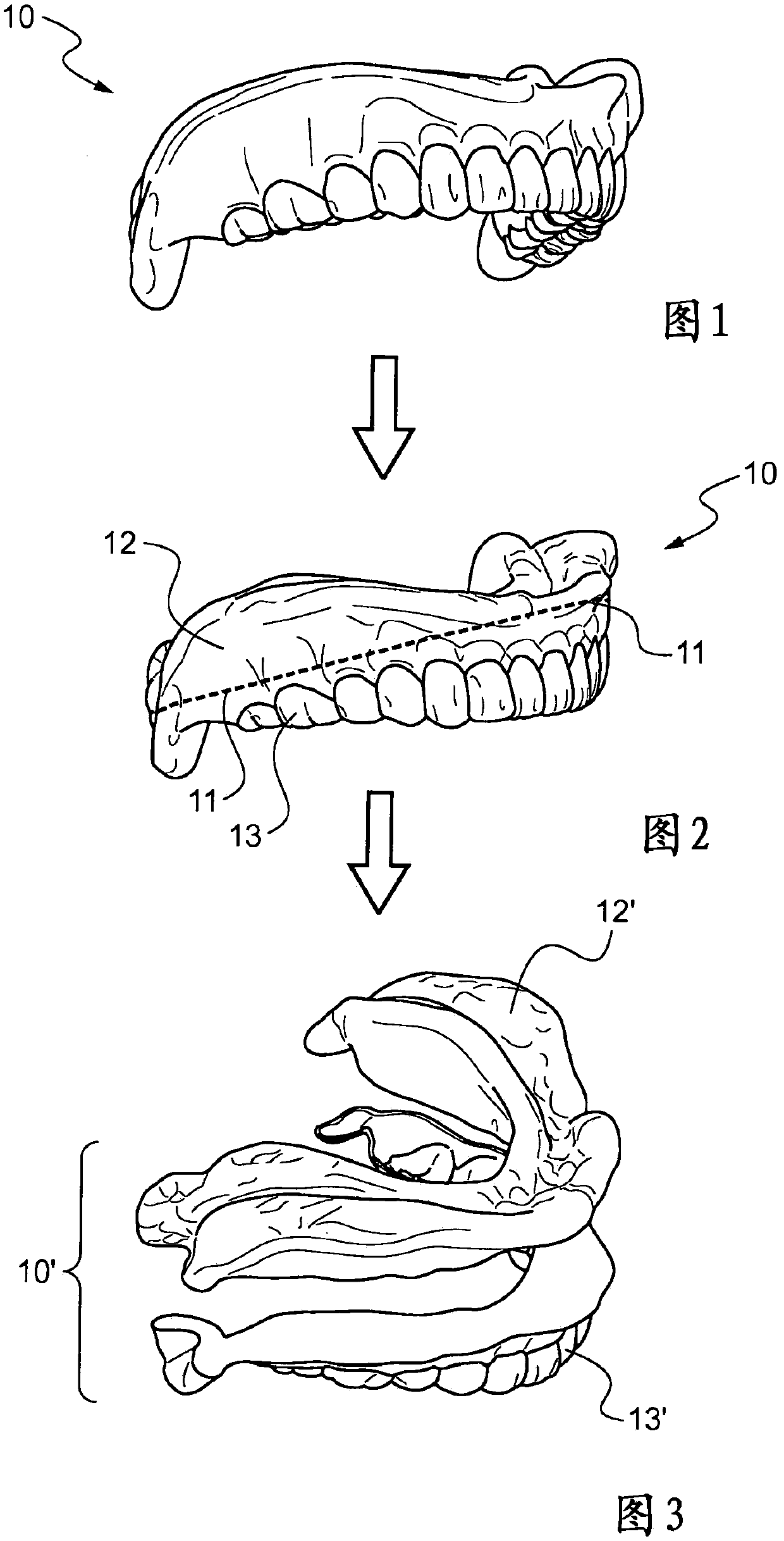

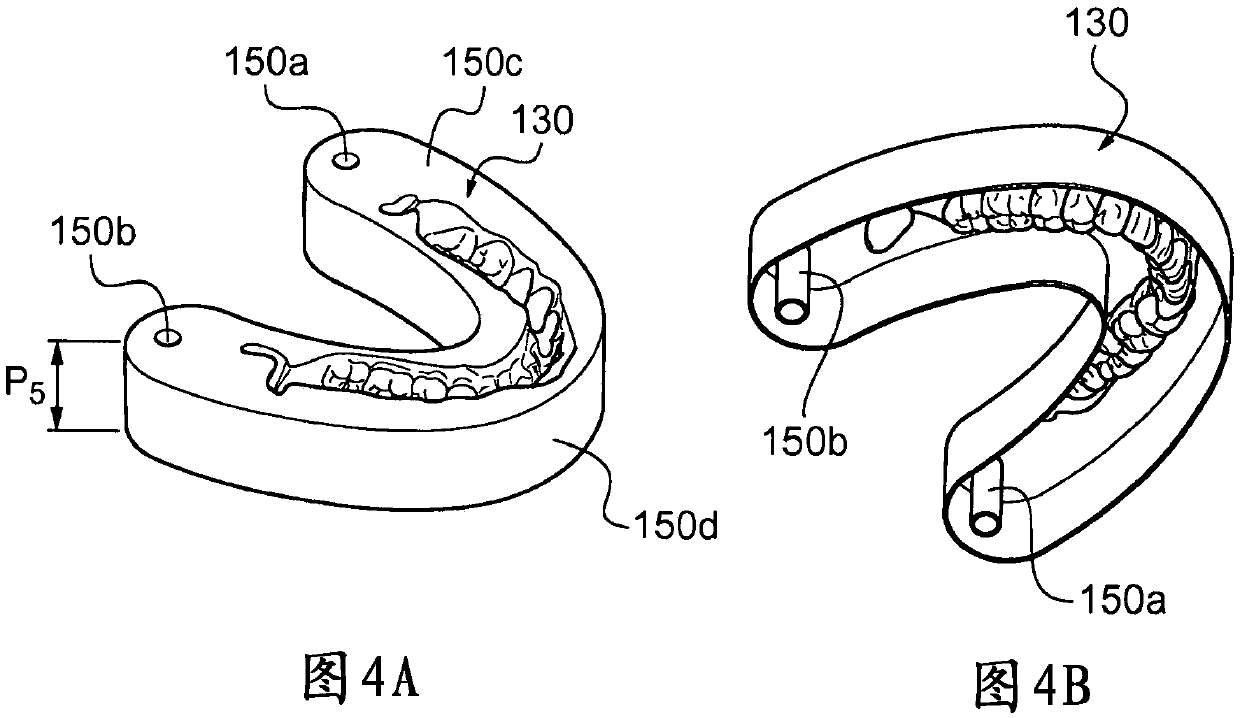

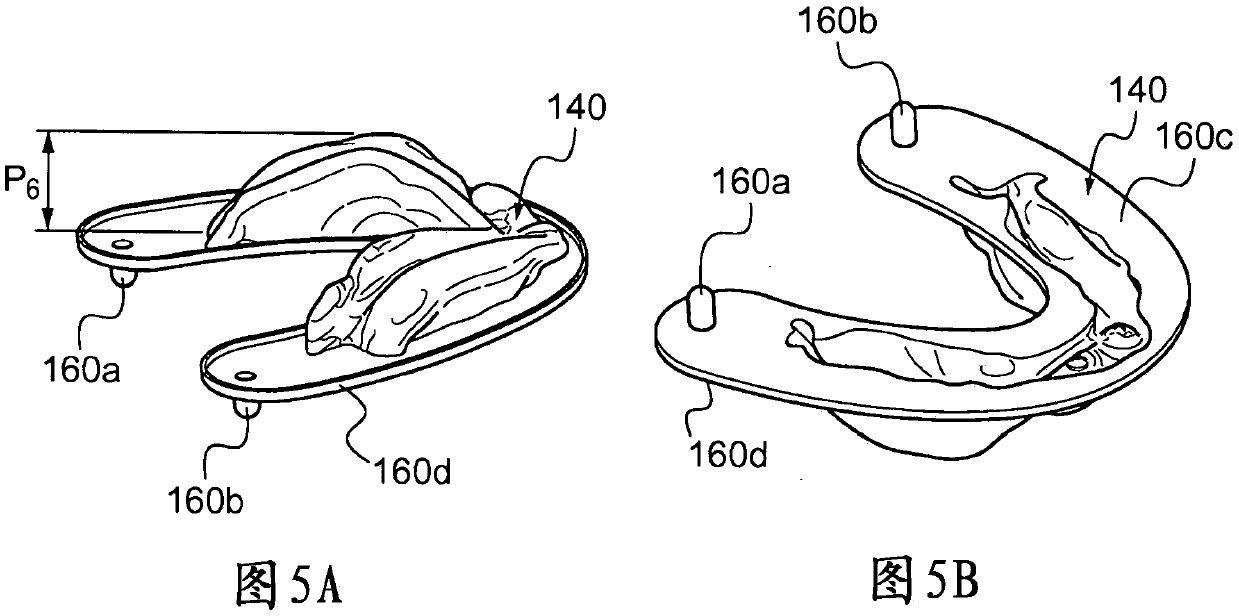

[0090] According to the first embodiment of the present invention Figure 1-10 A case of a method of manufacturing a complete denture, here an upper jaw, is shown. Figure 1-6 shows the CAD phase of the generative model, while Figure 7-10 The actual manufacturing phases in the strict sense are shown, including the actual making of the molds by additive manufacturing and then the actual making of the dentures with the help of the molds. Figure 11 The situation of two complete dentures obtained by the method of the present invention are upper jaw and lower jaw respectively, the lower jaw denture has been compared with the Figure 1-10 The steps shown are made in the same manner as when manufacturing dentures.

[0091] Such as figure 1 As shown, a digital file representing a model 10 of a three-dimensional removable denture has been created by a computer-aided design software (CAO) such as or The type of software is implemented in STL format. figure 1 The 3D impressio...

no. 2 approach

[0122] According to the second embodiment of the present invention Figures 12 to 16 The case of a method of manufacturing a partial denture with a Stellite body 22 , here an upper jaw, is shown. Figures 12 to 16 All shown before molding ( Figures 12 to 14 ) and after molding ( Figure 15 and 16 ) A designed mold 20 made by additive manufacturing.

[0123] therefore, Figure 12 Schematically shows an exploded perspective view of components forming a denture mold 20, which are an upper half-shell 21 (gingival part) and a lower half-shell 23 (teeth part) obtained after modeling, and a stellite body 22 . According to a slightly different perspective on the Figure 13 The bottom half-shell 23 is shown on top, which allows a better understanding of its shape. Stellite body 22 has been designed from the stamping step, as known to those skilled in the art.

[0124] The step of taking an impression is carried out by scanning directly in the oral cavity by an intraoral scanne...

no. 3 approach

[0137] According to the third embodiment of the present invention Figures 17 to 28 Shown is the case of a method of manufacturing a complete denture, here of the upper jaw, comprising support bars 49 for fixing the denture in the oral cavity by cooperating with six implants present in the jaw. Figures 17 to 2 3 shows the CAD phase which produces the model, while Figure 24-28 The actual manufacturing phase in the strict sense is shown, which consists of actually making the mold by additive manufacturing and then actually making the dentures with the help of the mold.

[0138] The support rod 49 is made by additive manufacturing. Support rods can also be made by lost wax casting.

[0139] Figure 17 A perspective view of the first member 37 (gingival part) of the denture model realized based on the impression-taking step is schematically shown. The upper portion 37 includes a portion 37a corresponding to the gum, a portion 37b corresponding to the palate, and a peripheral...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com