Device for removing pin bones from fish fillets

A fish fillet and equipment technology, applied in application, processing fish, slicing fish, etc., can solve the problems of electric motors hindering heat dissipation, shortened service life, high operating temperature, etc., meet high hygiene requirements, compact design, and avoid wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

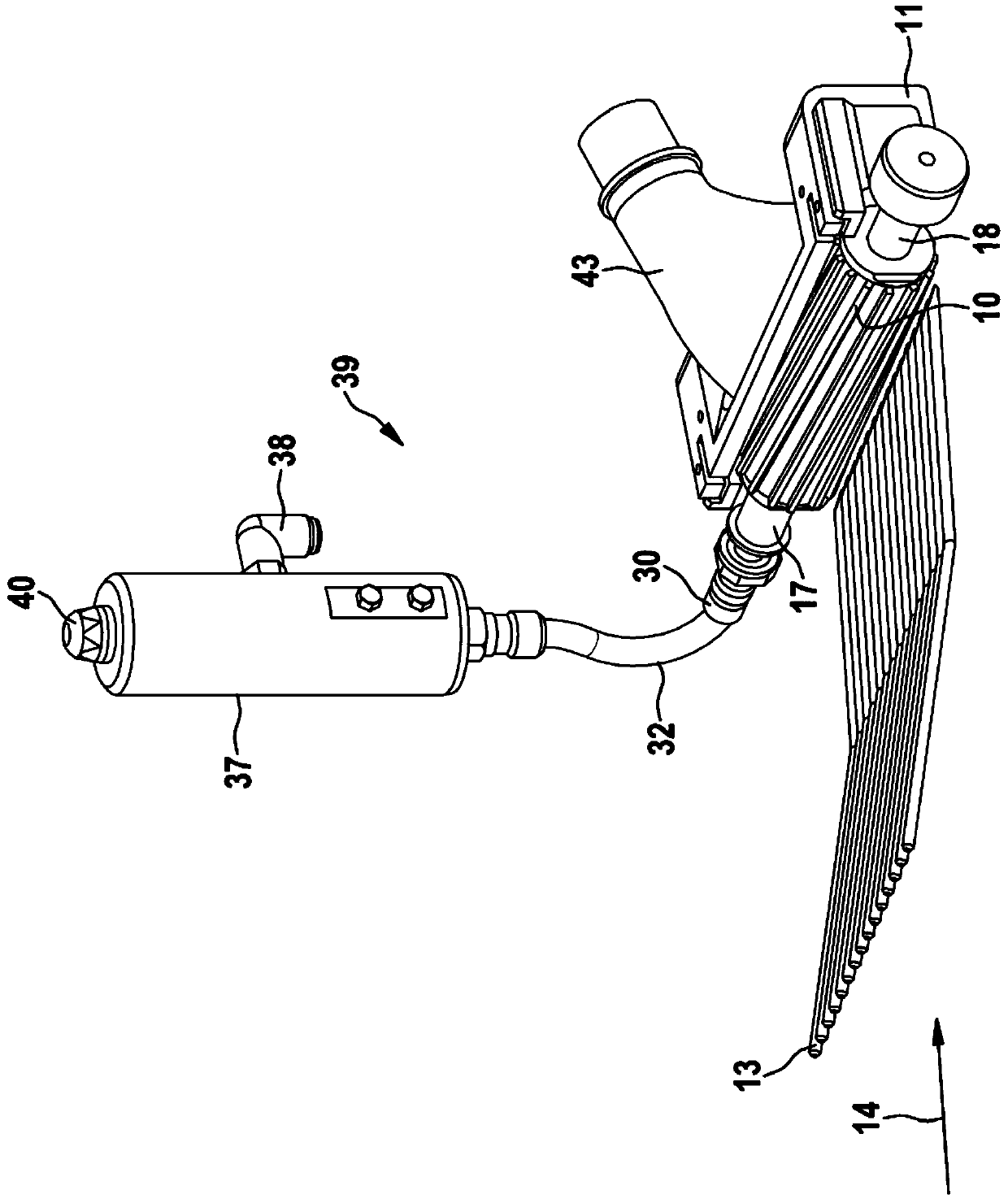

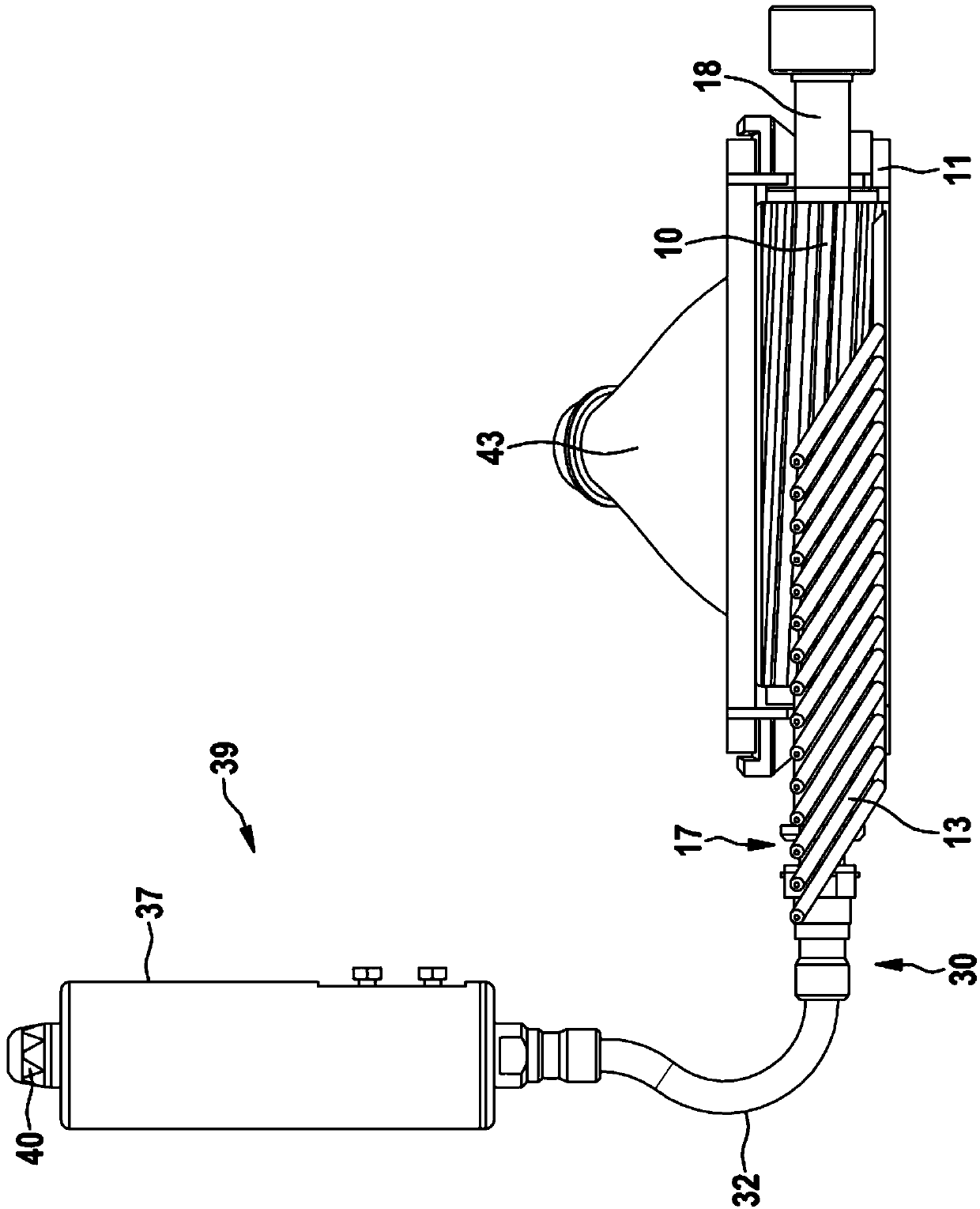

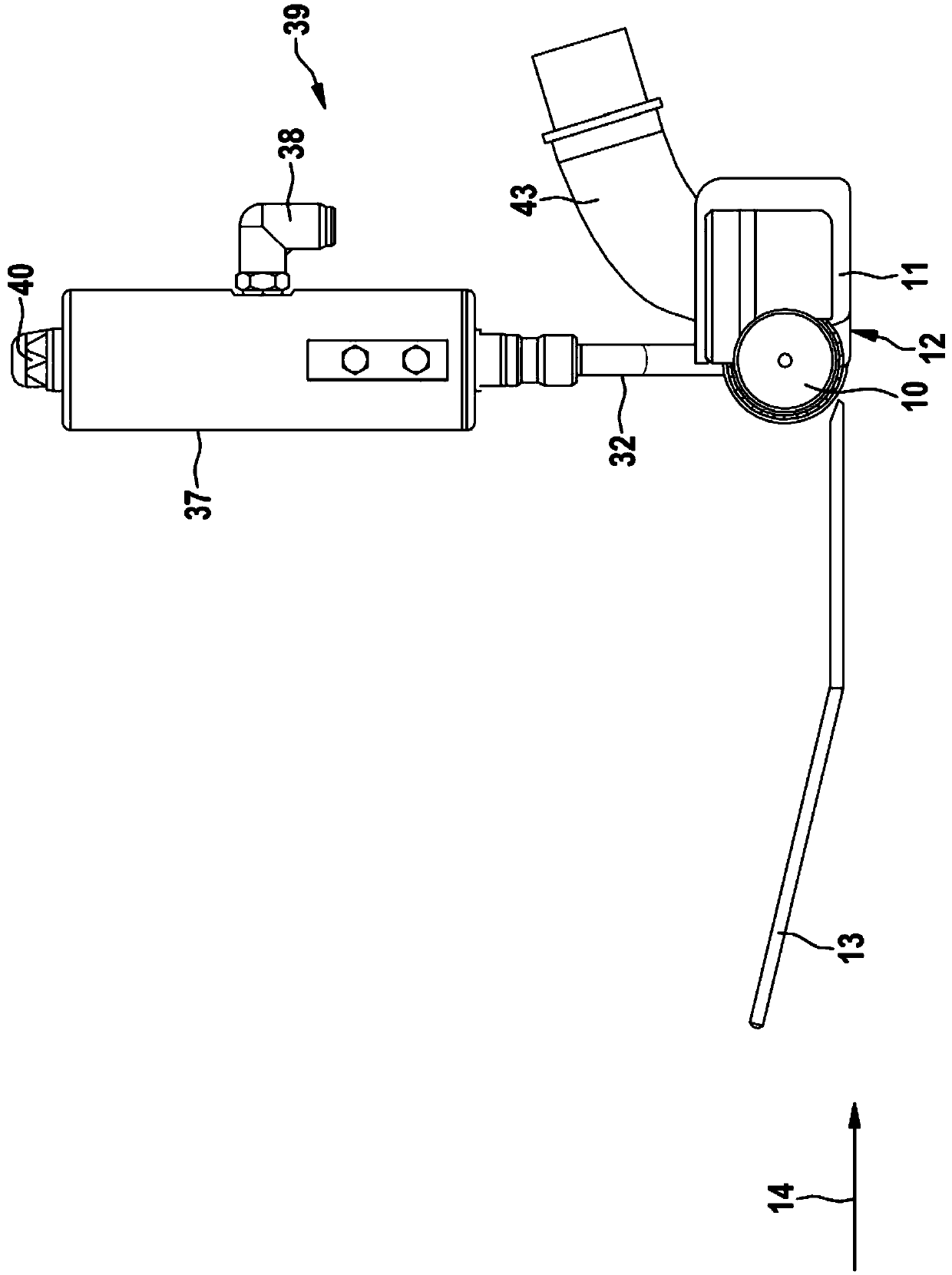

[0022] figure 1 The device according to the invention is shown in a perspective view. The device according to the invention is designed to remove pinbones from fish fillets fully automatically. For this purpose, fish fillets, not shown in the figures, are continuously fed for removal of the pin bones by means of a suitable conveyor device of the device according to the invention. For simplicity, such conveying means are not shown in the figures.

[0023] The device according to the invention comprises at least one profiled roll unit 10 which is rotatably mounted. A roller unit 10 with a pressure element 11 forms a clamping gap 12 . The roller unit 10 and the pressure unit 11 are configured to grasp the pin bone in the clamping gap 12 and to remove said pin bone from the fish fillet by applying a pulling force. Preferably, the device according to the invention comprises a hold-down clamp 13 with which the fish fillets conveyed to the device according to the invention in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com