Method for detecting parts of transition section of combustion chamber

A combustion chamber and transition section technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of narrowing the machining dimension tolerance range of parts in the transition section of the combustion chamber, affecting the feature size of parts, design reference deviation, etc., to achieve The detection results are intuitive, the detection efficiency is improved, and the effect of facilitating production and processing size adjustment and fitter repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

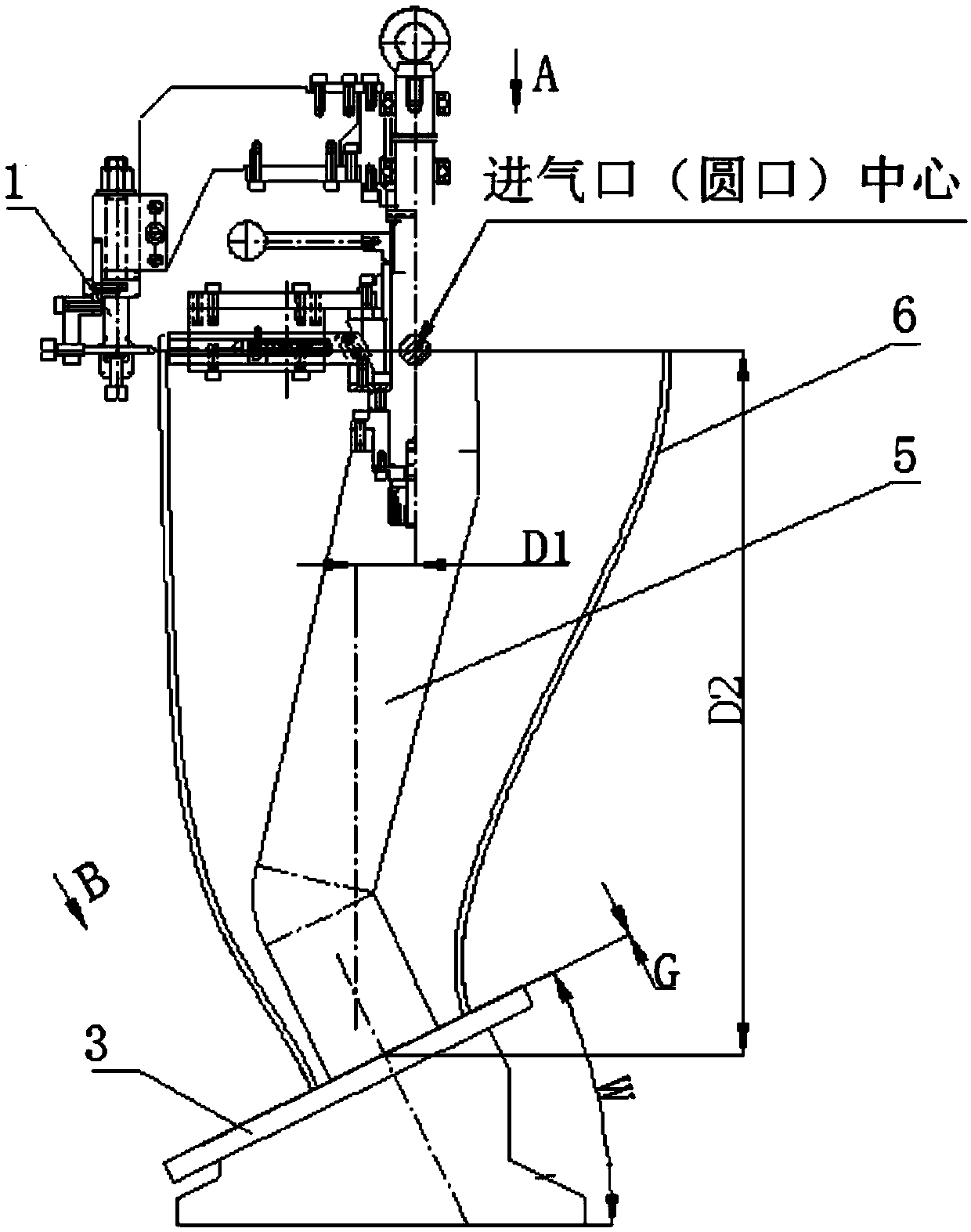

[0019] 1) Install the combustion chamber transition section parts on the comprehensive measuring tool:

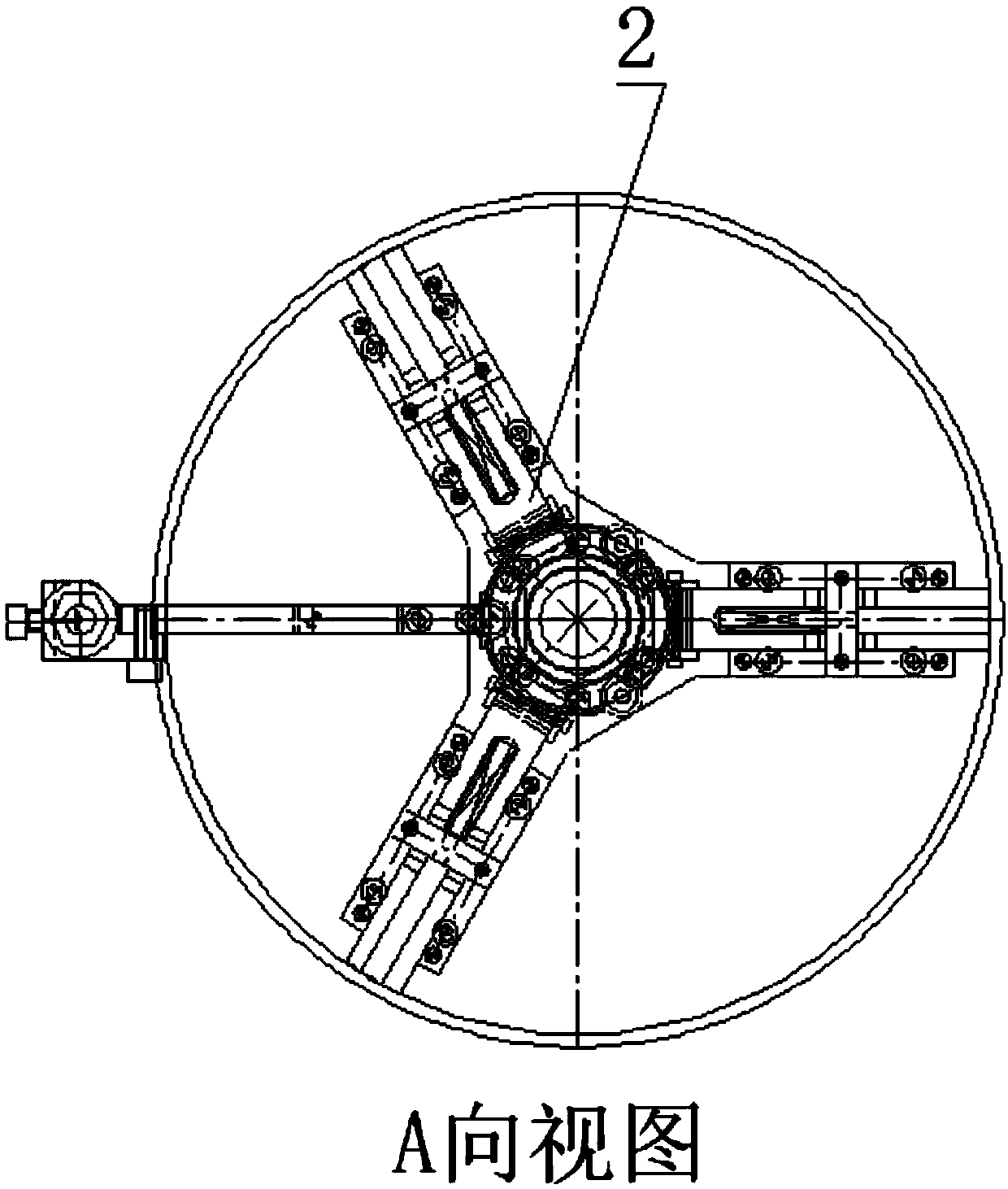

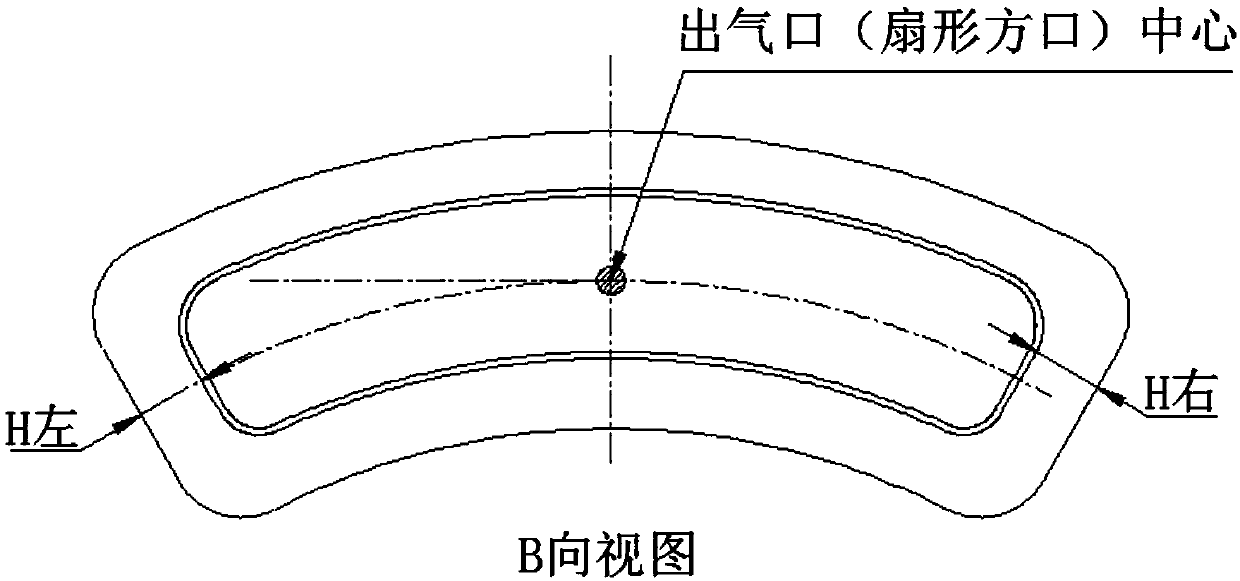

[0020] Lift and remove the tensioning mechanism 2 and the marking mechanism 1 from the column 5, pass the fan-shaped square mouth end of the combustion chamber transition section 6 down through the column 5, place it on the bottom plate 3, and then install the tensioning mechanism. Mechanism 2 and marking mechanism 1 naturally expand and tighten the inner side of the round mouth end of the air inlet of the transition section 6 of the combustion chamber to ensure that the three expansion block support points are in contact with the inner side wall of the round mouth end of the air inlet of the transition section of the combustion chamber.

[0021] 2) Detection of the transition section of the combustion chamber:

[0022] A. Adjust the scale corresponding to the tip of the marking needle on the needle marking mechanism 2 to the minimum value of the length dimension D2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com