Inorganic cementing material and preparation method thereof

An inorganic gelling material and mixer technology, applied in the field of construction materials, can solve the problems of high maintenance cost, insufficient durability and weather resistance, poor durability, etc., achieve reduced maintenance cycle and maintenance cost, and excellent sulfate corrosion resistance , Good anti-chloride ion penetration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

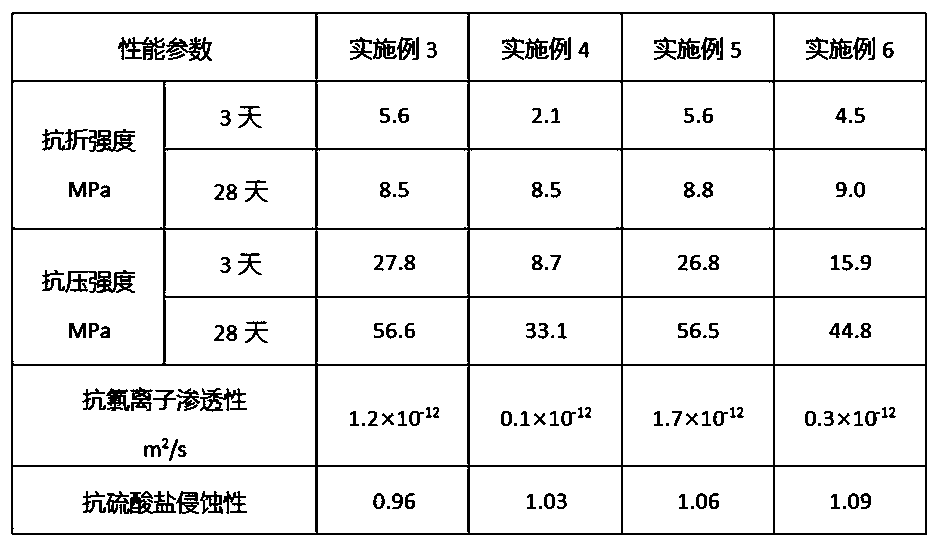

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention discloses a micronano-scale inorganic gelling material with high resistance to chloride ion penetration and high resistance to sulfate erosion and a preparation method thereof for use in marine and water conservancy projects. In the first embodiment, the inorganic cementitious material is composed of the following components in parts by weight as follows, including 50-90 parts of cement, 1-10 parts of silicon micropowder, 5-30 parts of slag micropowder, and 5-10 parts of fly ash parts, mineral fiber 1-10 parts.

[0031] In the second embodiment, the inorganic cementitious material is composed of the following components in parts by weight, including 60-80 parts of cement, 1.5-8.5 parts of silica micropowder, 10-20 parts of slag micropowder, 5-10 parts of fly ash, 1-5 parts of mineral fiber.

[0032] Specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com