Vehicle assembly line

An assembly line and vehicle assembly technology, applied in motor vehicles, transportation and packaging, etc., can solve problems such as inability to adapt to the market and product diversification, achieve real-time tracking and tracing, promote lean production, and reduce production problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The preferred embodiments of the present invention will be described below with reference to the drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention and are not intended to limit the protection scope of the present invention.

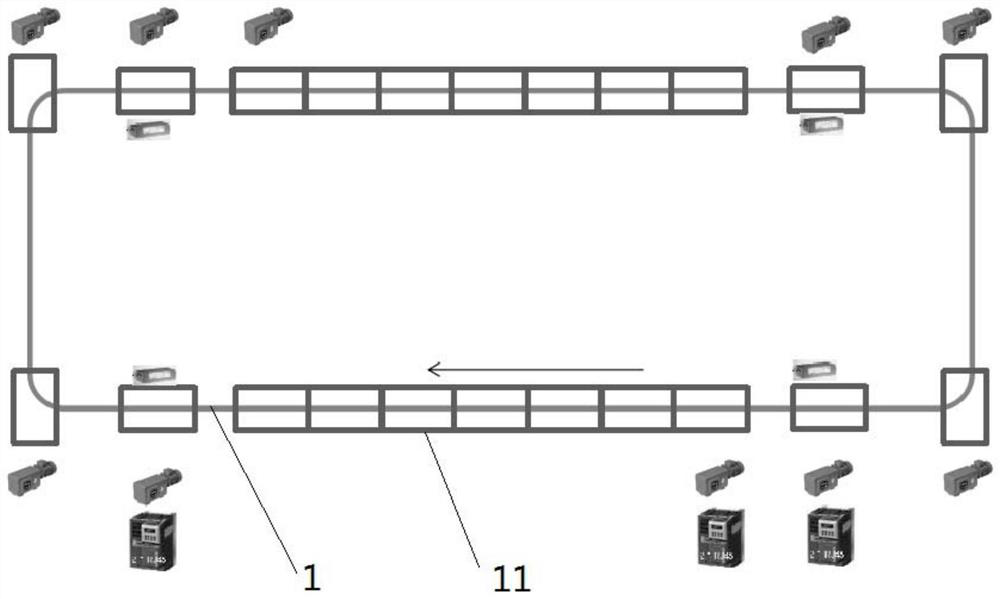

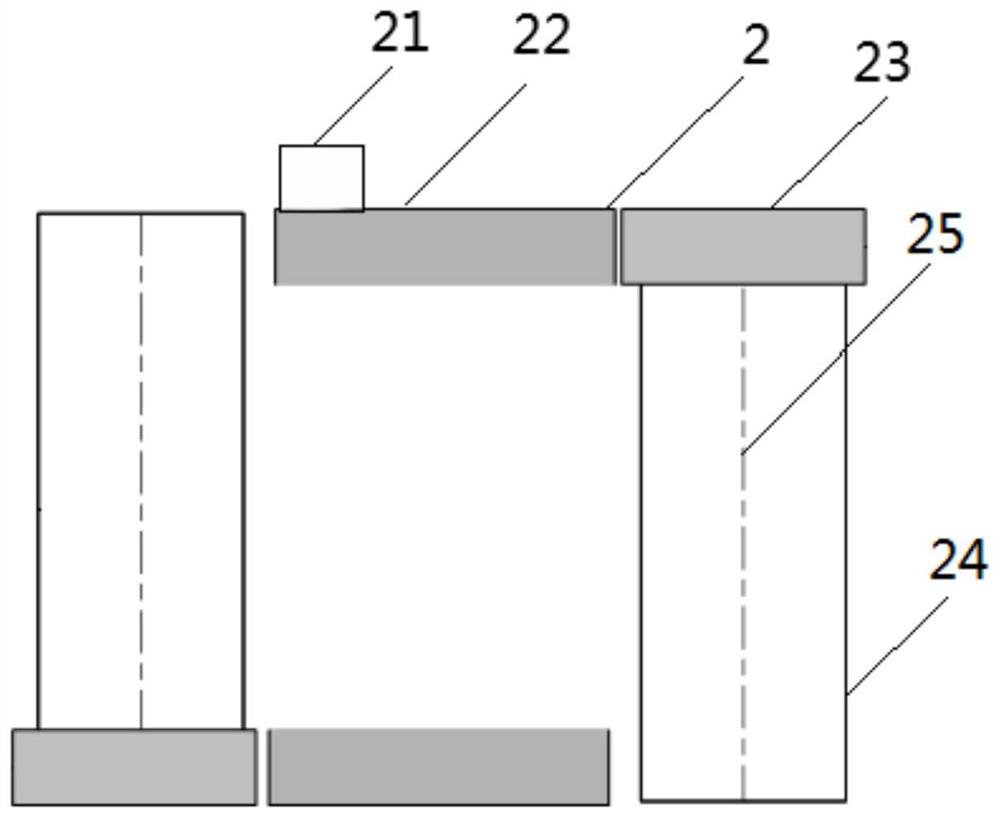

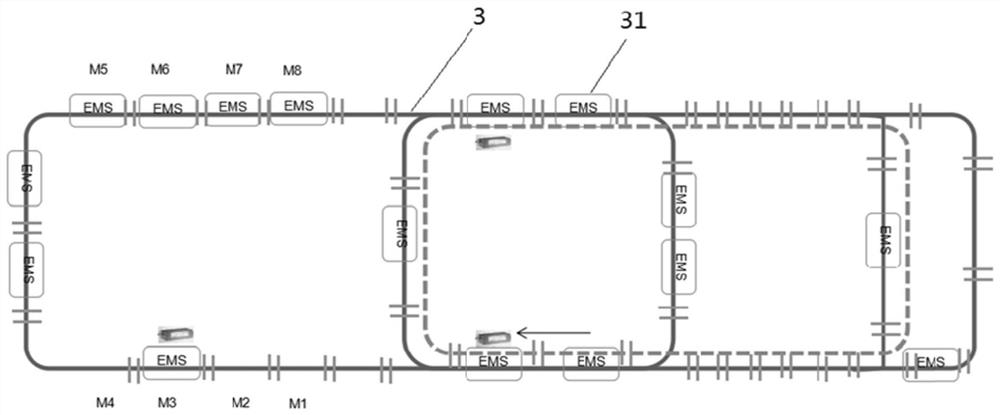

[0036]In order to meet individual needs, the cost of mass production is used to produce a large number of products that meet the individual needs of users. The invention assembles parts into products, applies computer-aided technology to the assembly process, and emphasizes the integration and adjustment of stations, the balance of workloads at each station, the parallel design of processes and the smoothness of logistics, thereby realizing agile manufacturing (AgileManufacture, AM ), effectively realize the automation and flexibility of vehicle product assembly, and improve the efficiency of vehicle assembly line assembly.

[0037]The present invention provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com