Manufacturing method of printed circuit board for signal generator

A printed circuit board and signal generator technology, which is applied in the fields of printed circuit manufacturing, printed circuit, multilayer circuit manufacturing, etc., can solve the problems of low conversion efficiency of antenna transmission and reception, small installation contact area, line signal loss, etc. To achieve the effect of ensuring the conversion efficiency of transmission and reception, increasing the contact area of the connection, and extending the length of the antenna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for manufacturing a printed circuit board for a signal generator, and the specific process is as follows:

[0029] (1) Cutting: cut out the core board according to the board size 520mm×620mm, the thickness of the core board is 0.8mm, and the thickness of the outer layer of copper foil is 1OZ.

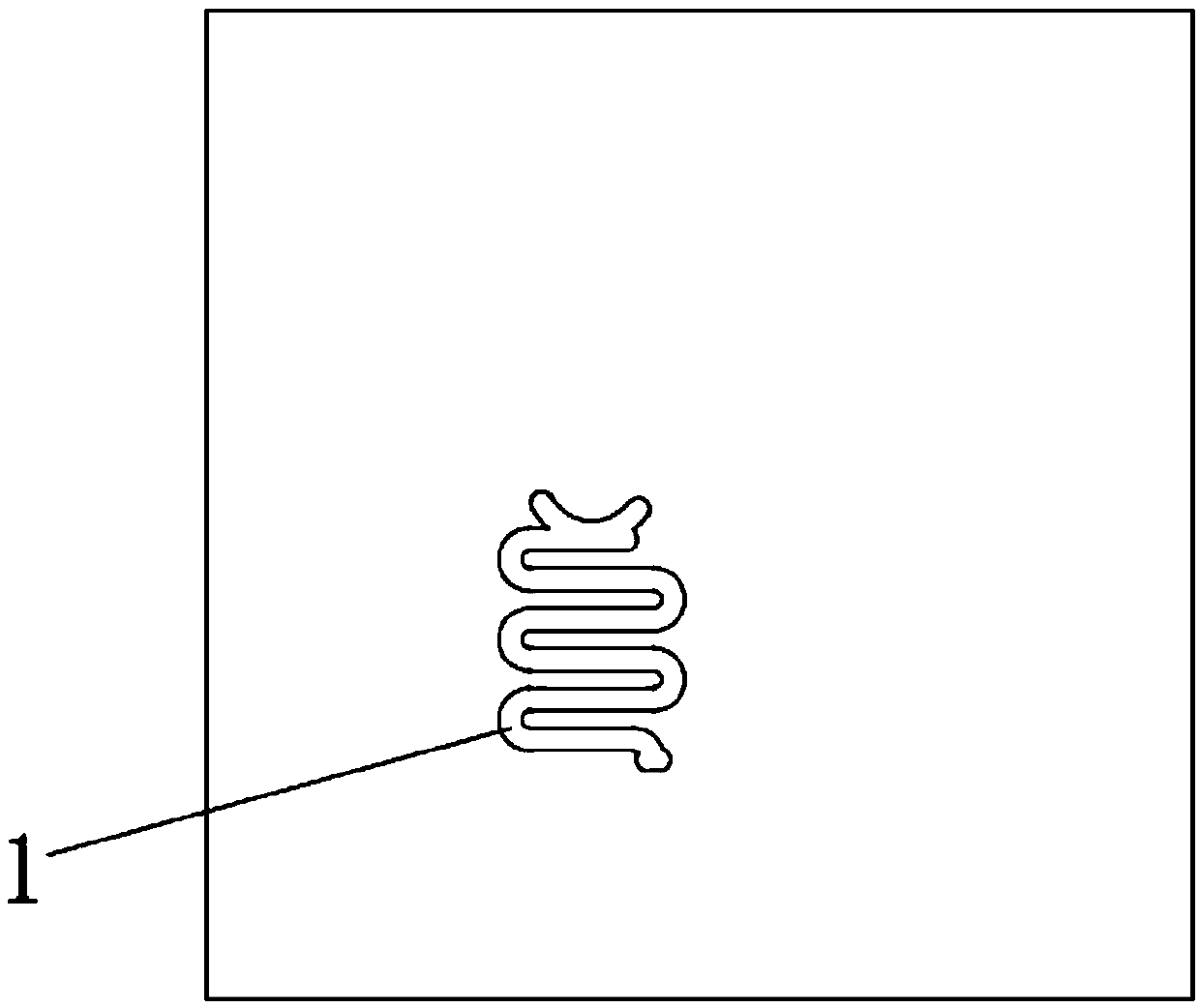

[0030] (2) Inner layer circuit production (negative film process): Inner layer graphics transfer, use a vertical coating machine to coat a photosensitive film on the core board, the film thickness of the photosensitive film is controlled at 8 μm, and a fully automatic exposure machine is used to 5-6 grids The exposure ruler (21-grid exposure ruler) completes the exposure of the inner layer circuit on the core board; the inner layer is etched, and the inner layer circuit is etched out of the exposed and developed core board. Include the earthworm wire 1 (such as figure 1 shown); the inner layer AOI, and then check the open and short circuits, lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com