Orthohexagnal MWT solar half-cell, assembly and arrangement method

A solar cell and regular hexagon technology, applied in the field of solar cells, can solve the problems of large current collected by thin grid lines, long distance between thin grid lines and holes, and high heat loss of thin grid lines, so as to reduce cutting losses and reduce Environmental pollution and waste of resources, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

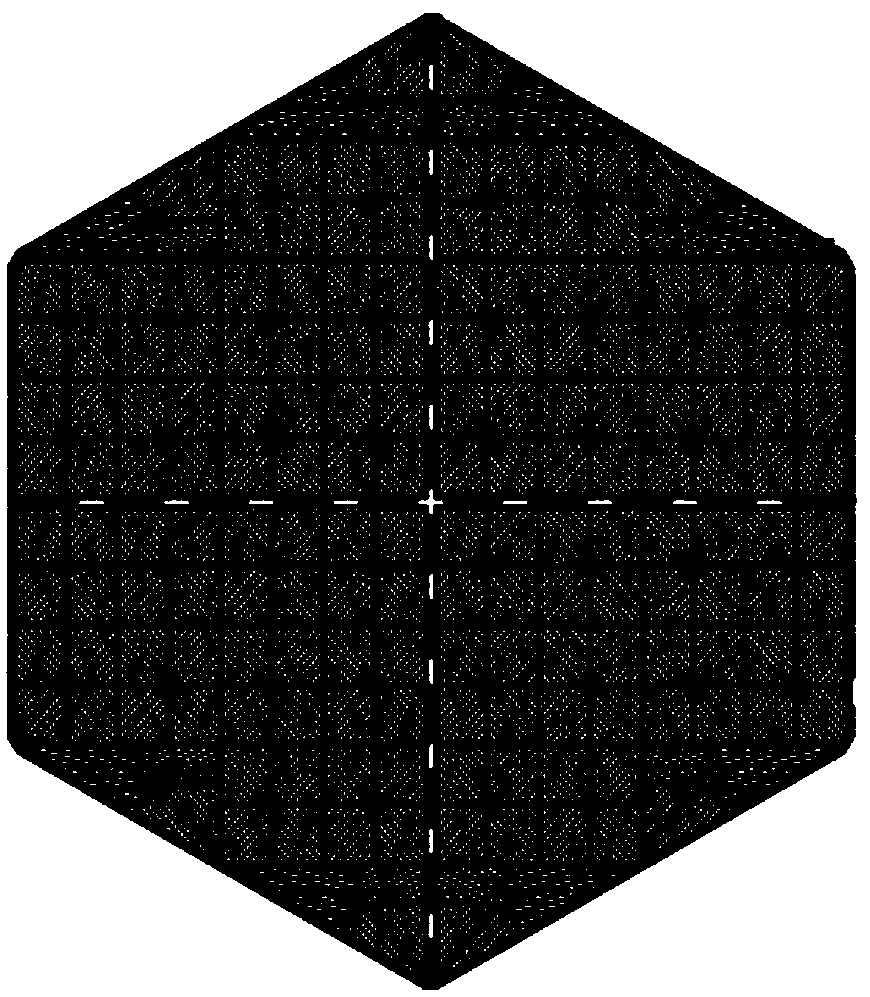

[0029] Such as figure 1 As shown, the regular hexagonal MWT solar cell proposed by the present invention has a total of 48 lattice holes. In the middle area, laser scribing can be done along one of the longest diagonal lines, or along the sag of one of the opposite sides. Line laser scribing to form two symmetrical MWT solar cell halves 9 .

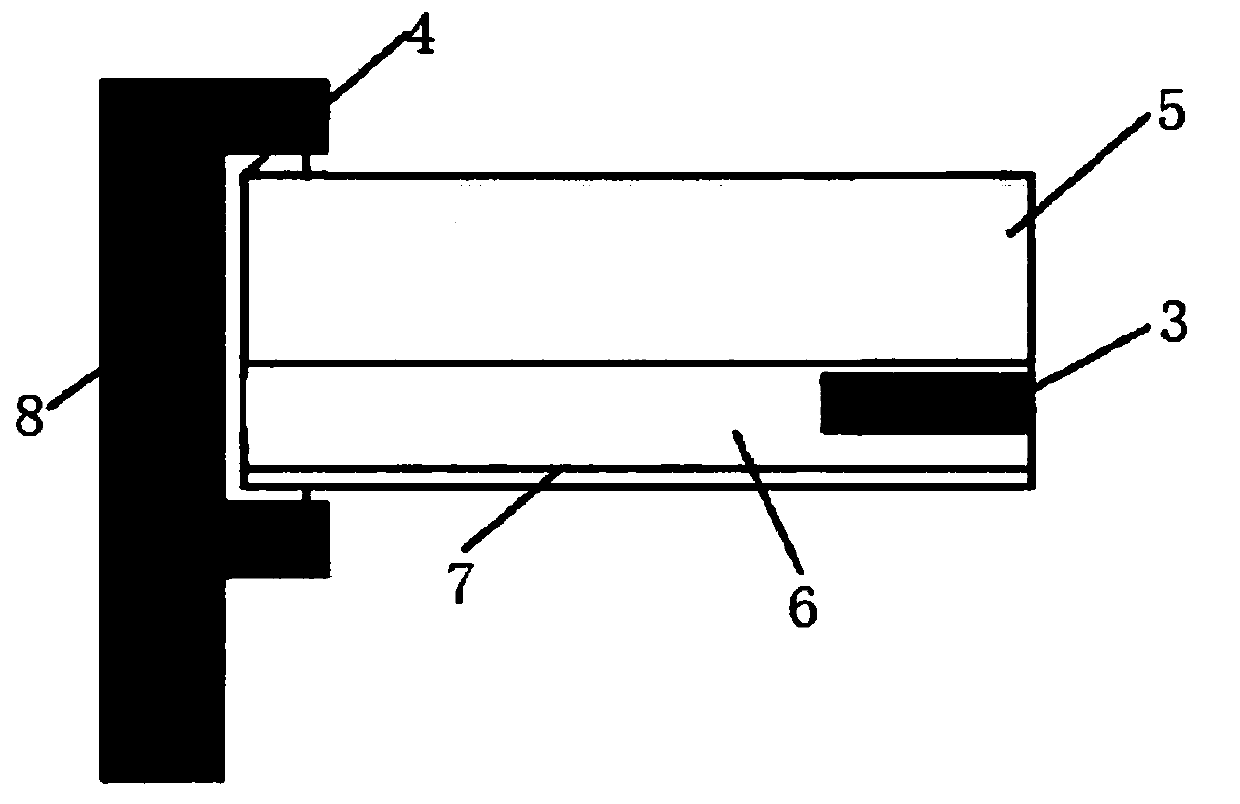

[0030] The encapsulation loss of solar cell components includes electrical loss and optical loss. In the regular hexagonal MWT solar cell half-cell module proposed by the present invention, the cells are connected by conductive glue and copper foil on the conductive backplane, so the electrical loss includes the mismatch loss of the cells, the resistance of the fine grid wires on the front Loss, resistive loss on conductive glue and conductive copper foil, etc. Since there is no soldering tape, the electrical loss is smaller. For the half-chip, the current is further reduced, so that the electrical losses are further reduced. The half ...

Embodiment 2

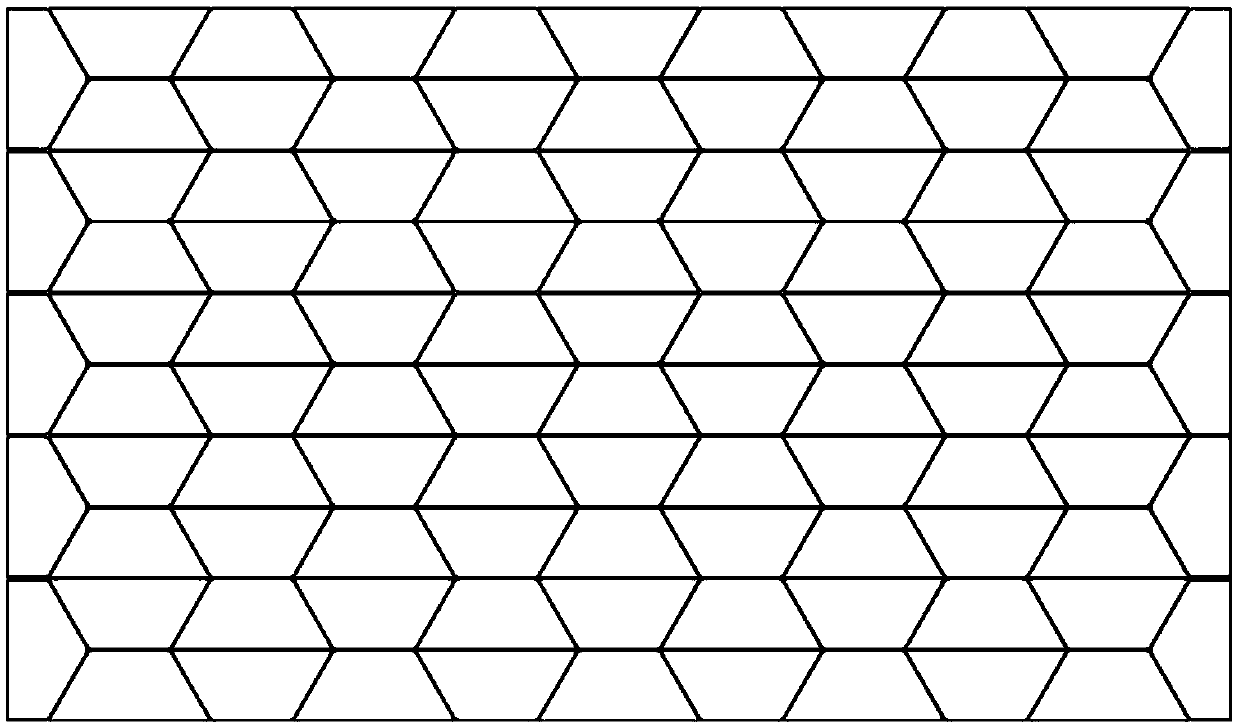

[0041] Such as Figure 4 As shown, the present invention also discloses an arrangement scheme of a regular hexagonal MWT solar cell and a half sheet to form a module, which is characterized in that it can be used Figure 5 The assumed basic unit 9 is combined, and the regular hexagon 10 formed by the assumed basic unit is replaced by a whole piece, so that a regular hexagonal MWT solar cell module can be formed.

[0042] Table 1

[0043]

[0044]

[0045]As shown in Table 1, the advantage of the arrangement scheme of regular hexagonal MWT solar cells and half sheets to form modules is that compared with regular hexagonal regular modules, using half sheets and full sheets to form MWT solar cell modules can reduce Cutting loss, while greatly reducing the blank gap area of the module, the effective area ratio of the module, the efficiency of the module and the power per unit area of the module are significantly improved; compared with the conventional MWT module, altho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com