Chip packaging structure, chip packaging method, and display device

A packaging structure and chip packaging technology, applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as chip and circuit board hole phenomenon, chip packaging reliability reduction, etc., to improve production efficiency, fill The effect of improving efficiency and reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to further illustrate the chip packaging structure, packaging method, and display device provided by the embodiments of the present invention, a detailed description will be given below in conjunction with the accompanying drawings.

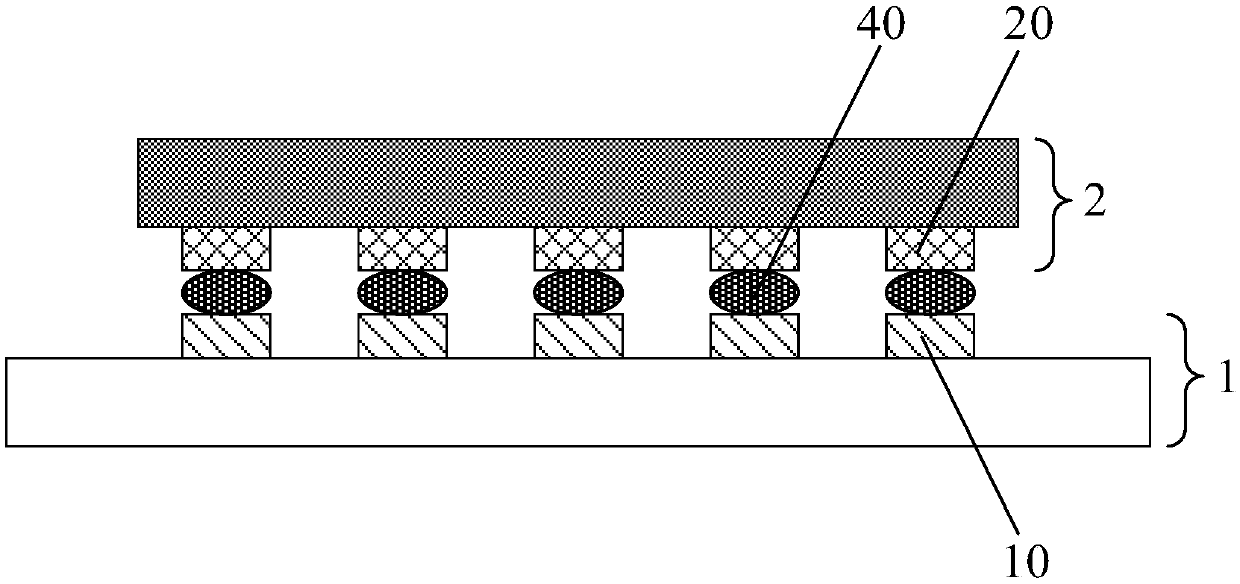

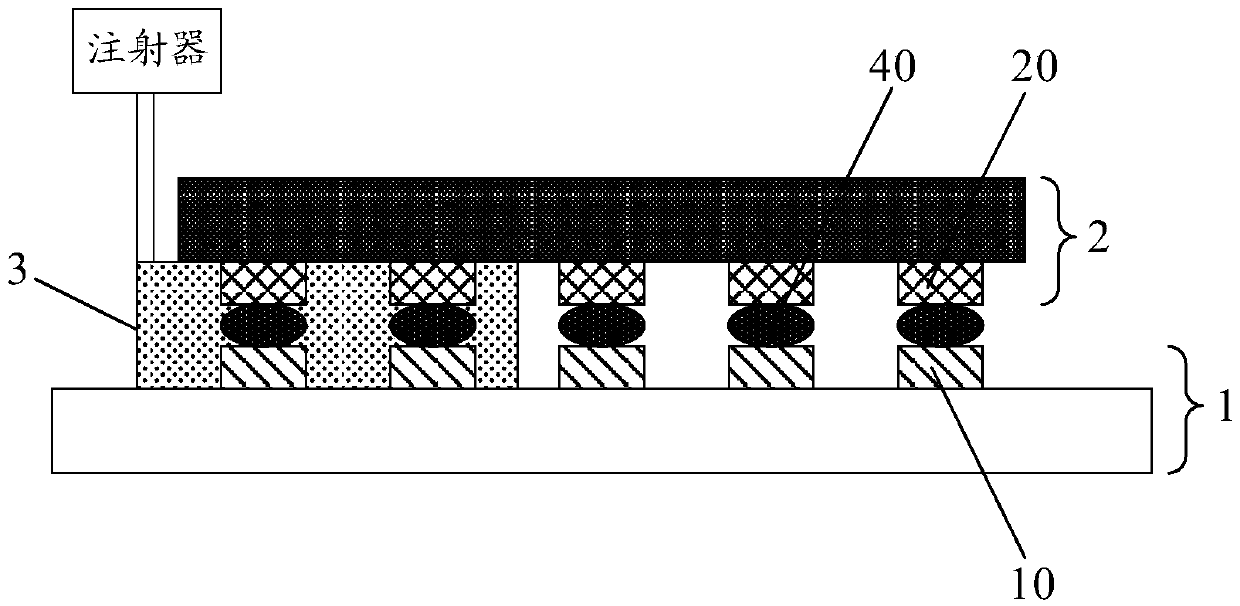

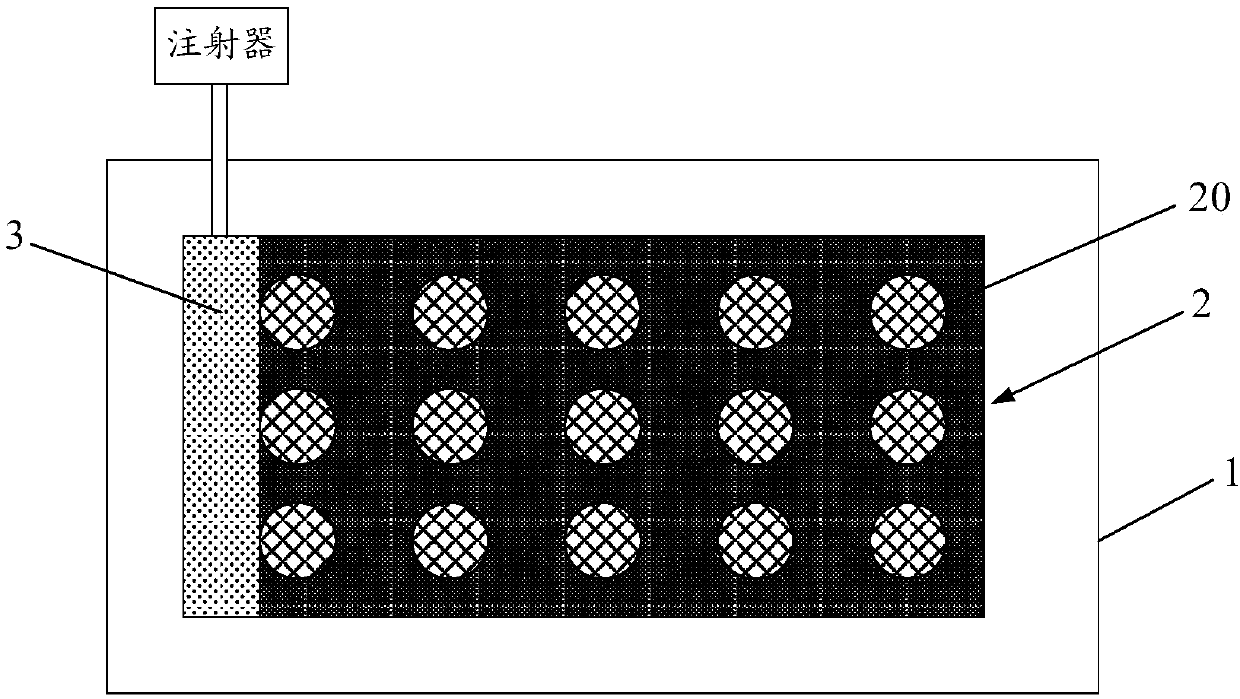

[0069] like figure 1 As shown, when the chip 2 is packaged on the circuit board 1, the chip 2 is generally packaged on the chip package area on the circuit board 1, and the chip package area includes pads corresponding to the pins 20 in the chip 2 one-to-one. 10. When packaging, first deposit solder balls 40 on the pins 20 of the chip 2, and then place the side of the chip 2 with the pins 20 facing the circuit board 1, so that each pin 20 in the chip 2 is connected to the circuit board 1. Contact the corresponding pad 10, and then heat the solder ball 40 between the pin 20 and the pad 10, so as to realize the electrical connection between the pin 20 and the corresponding pad 10; as figure 2 and image 3 As shown, the underfill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com