Method for measuring working time of plant mixed emulsified asphalt cold recycled mixtures

A technology of cold recycled mixture and emulsified asphalt, applied in the direction of material inspection products, etc., can solve the problems of relying on subjective judgment and the results vary greatly, and achieve the effect of easy mastery and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

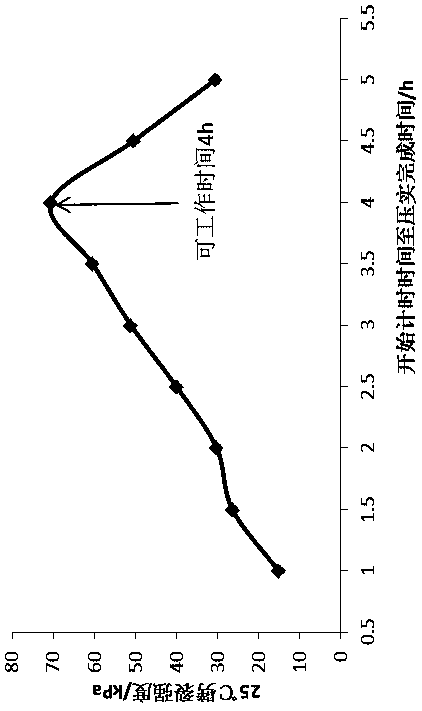

[0027] Example A method for measuring the working time of emulsified asphalt cold recycled mixture, comprising the following steps:

[0028] ⑴Preparation plant mixed emulsified asphalt cold recycled mixture:

[0029] 4.0 parts of emulsified asphalt (3.0% emulsifier), 1.5 parts of cement, 1.5 parts of mineral powder, 3.0 parts of pre-wet water, 80 parts of milling material, and 10 parts of crushed stone (parts by weight, the total mass is 4050g). Then add the milling material and gravel to the asphalt mixture mixing pot in proportion, add pre-wet water, and stir for 90 seconds; then add emulsified asphalt, and stir for 90 seconds; finally add mineral powder and cement, and stir for 90 seconds to complete the preparation. Repeat the above steps to complete the preparation of 9 parts of mixture mixture.

[0030] Start the timer after each mix is blended.

[0031] ⑵ Loading samples to simulate the transportation process:

[0032] Place a Φ148mm×20mm circular stainless steel g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com