Axial swirler structure with oil spraying structure blades

A swirler and axial technology, which is applied in the field of gas turbine engines, can solve the problems of high-altitude ignition, incomplete combustion, and great environmental damage, so as to improve the oil-gas mixing effect, improve combustion efficiency, and improve stealth performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described now in conjunction with accompanying drawing:

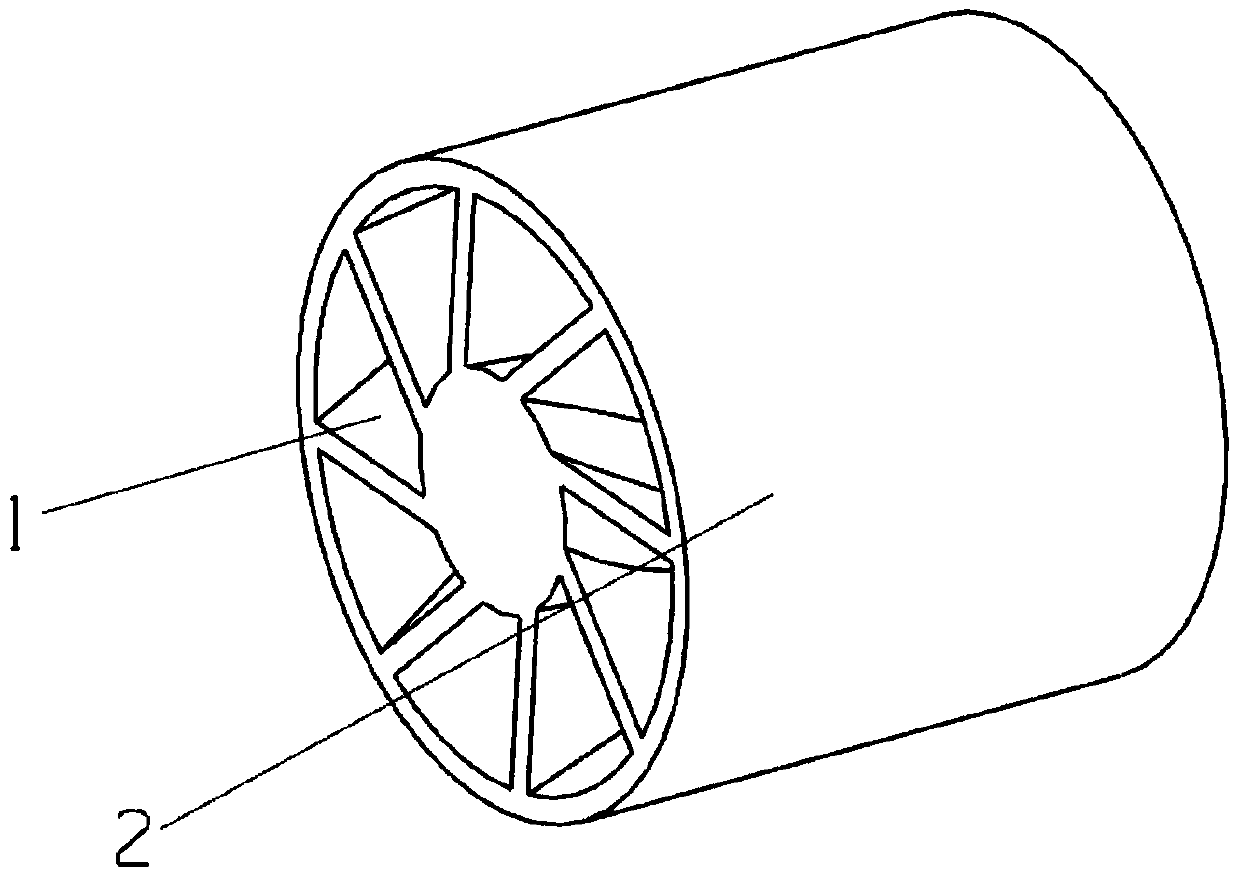

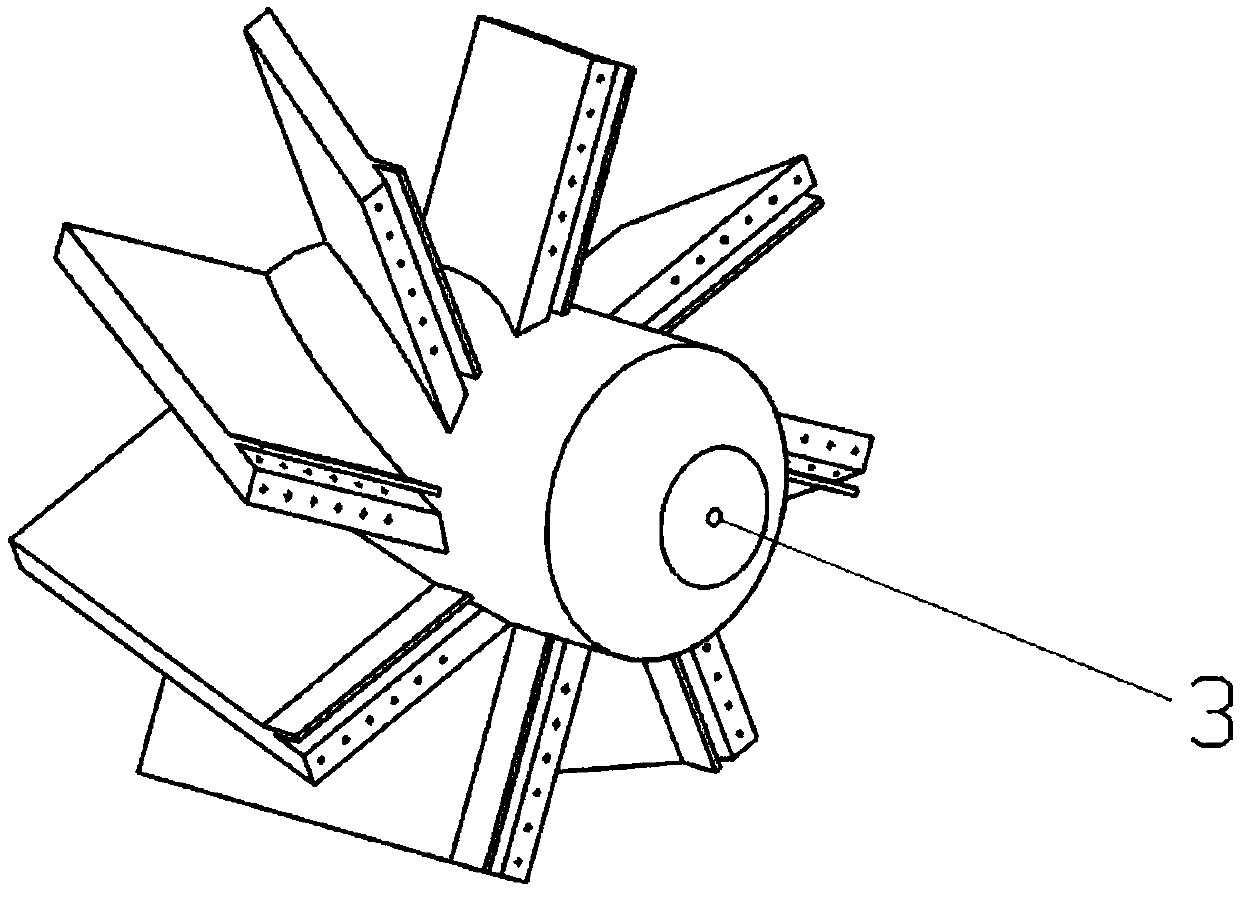

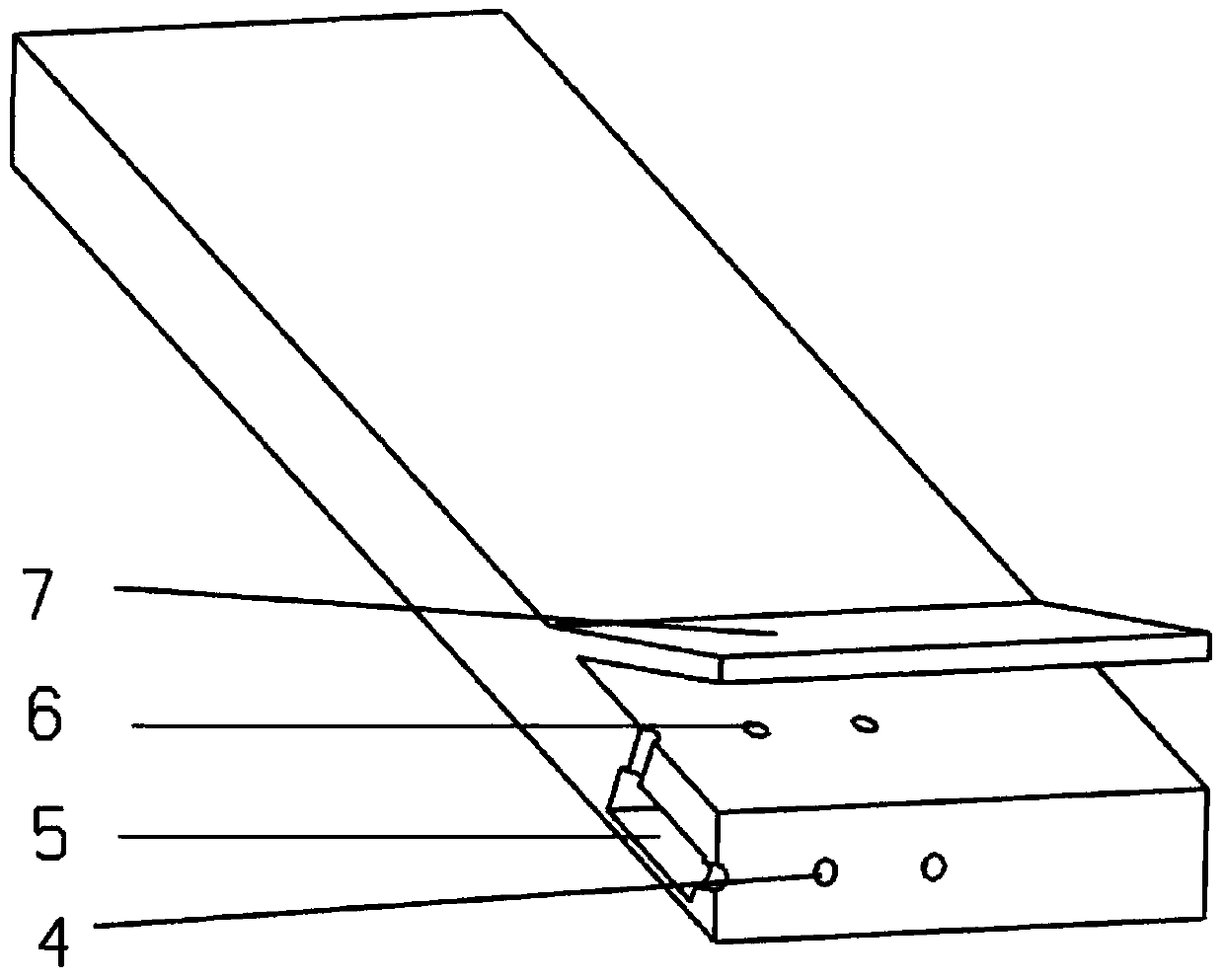

[0021] combine figure 1 , figure 2 , image 3 , The present invention provides an axial swirler structure with blades of fuel injection structure. The blades of the axial swirler have fuel passages inside and are connected with fuel injection holes, and a support plate is arranged on the outside. figure 1 is a three-dimensional schematic diagram of an axial swirler with an oil-injection structure vane, figure 2 It is a three-dimensional schematic diagram of the interior of the axial swirler with oil-injection structure blades, image 3 A cross-sectional diagram of a single blade.

[0022] fuel from image 3 The fuel passage shown in (5) enters from the center oil passage figure 1 (1) In the blade of the axial swirler, the support plate protrudes and forms a certain angle with the blade, and the inlet air flows through image 3 (7) When supporting the plate, the airfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com