Neutron beam window fastening and sealing device

A sealing device and neutron beam technology, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., can solve the problems of complex mechanism, complex action, easy interference, etc., and achieve simple mechanism, not easy to collide, and high efficiency The effect of fastening and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

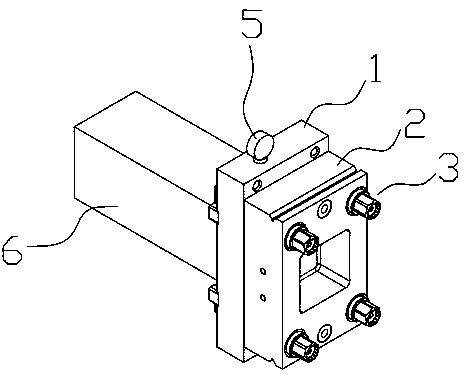

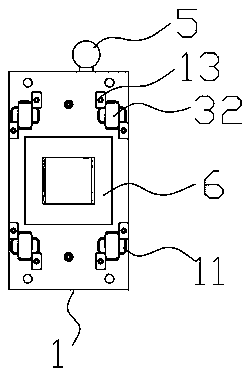

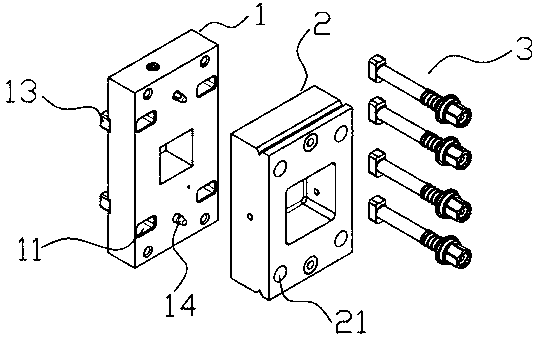

[0050] A neutron beam window fastening and sealing device, such as Figure 1~9As shown, it includes a neutron takeover flange 1 , a neutron beam window, fastening bolts 3 and sealing components 4 . The neutron flange 1 is also provided with a vacuum gauge 5 . The rear side of the neutron flange 1 is connected with the neutron channel 6 .

[0051] The neutron beam window 2 is provided with four first bolt holes 21 in a rectangular array; the neutron adapter flange 1 is provided with four second bolt holes 11 corresponding to the first bolt holes 21 .

[0052] Fastening bolt 3 comprises screw rod 31 and the bolt head 32 that is positioned at screw rod 31 one ends, and screw rod 31 other ends are provided with fastening nut 33; The first elastic component 35 , one end of the first elastic component 35 withstands the fastening nut 33 , and the other end is used to withstand the neutron adapter flange 1 . The fastening nut 33 is threadedly connected with the screw rod 31 . The ...

Embodiment 2

[0063] This embodiment is the second embodiment of the neutron beam window fastening and sealing device of the present invention. The difference from Embodiment 1 is that the fastening bolts 3 include the same number of forward fastening bolts and reverse fastening bolts; The two fastening bolts 3 of the first bolt hole 21 at the diagonal position are both positive fastening bolts or reverse fastening bolts.

[0064] The other components and connections are the same as in Embodiment 1.

[0065] The four first bolt holes 21 form a rectangular array, and the corresponding fastening bolts 3 also form a rectangular array. The difference between the forward fastening bolt and the reverse fastening bolt is that the rotation direction is opposite when the fastening nut 33 is tightened. Such as Figure 10 As shown, the fastening nut 33 of the forward fastening bolt rotates clockwise when tightened, and the fastening nut 33 of the reverse fastening bolt rotates counterclockwise when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com