Fixture tool for gear shaping processing

A technology of tooth processing and fixture, applied in the direction of manufacturing tools, components with teeth, metal processing equipment, etc., can solve the problems of low processing precision, large processing error, inaccurate positioning of fixtures, etc., to achieve high processing precision, reduce The effect of machining error and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

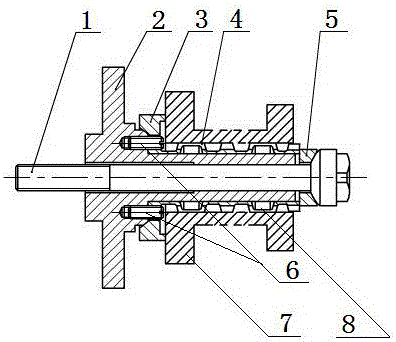

[0015] figure 1 It is a schematic diagram of the structure of the present invention. The present invention proposes a fixture tool for gear shaping processing, which is characterized in that it includes a tie rod 1, a core seat 2, and a replaceable bellows sleeve 4. The tie rod 1 is nested inside the core seat 2. , the replaceable bellows 4 is nested outside the core base 2, the core base 2, the right end of the replaceable bellows 4 and the tie rod 1 are provided with an upper gasket 5, and the left end of the core base 2 is provided with a lower gasket 3 , A blank 7 to be processed is arranged between the upper gasket 5 and the lower gasket 3, and the lower gasket 3 is fastened and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com