Filling building block for pouring and construction method thereof

A construction method and block technology, applied in the direction of construction, building components, building structures, etc., can solve the problems of increased labor force, poor mesh surface fixing effect, and low surface flatness, so as to achieve convenient construction and firm fixation , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

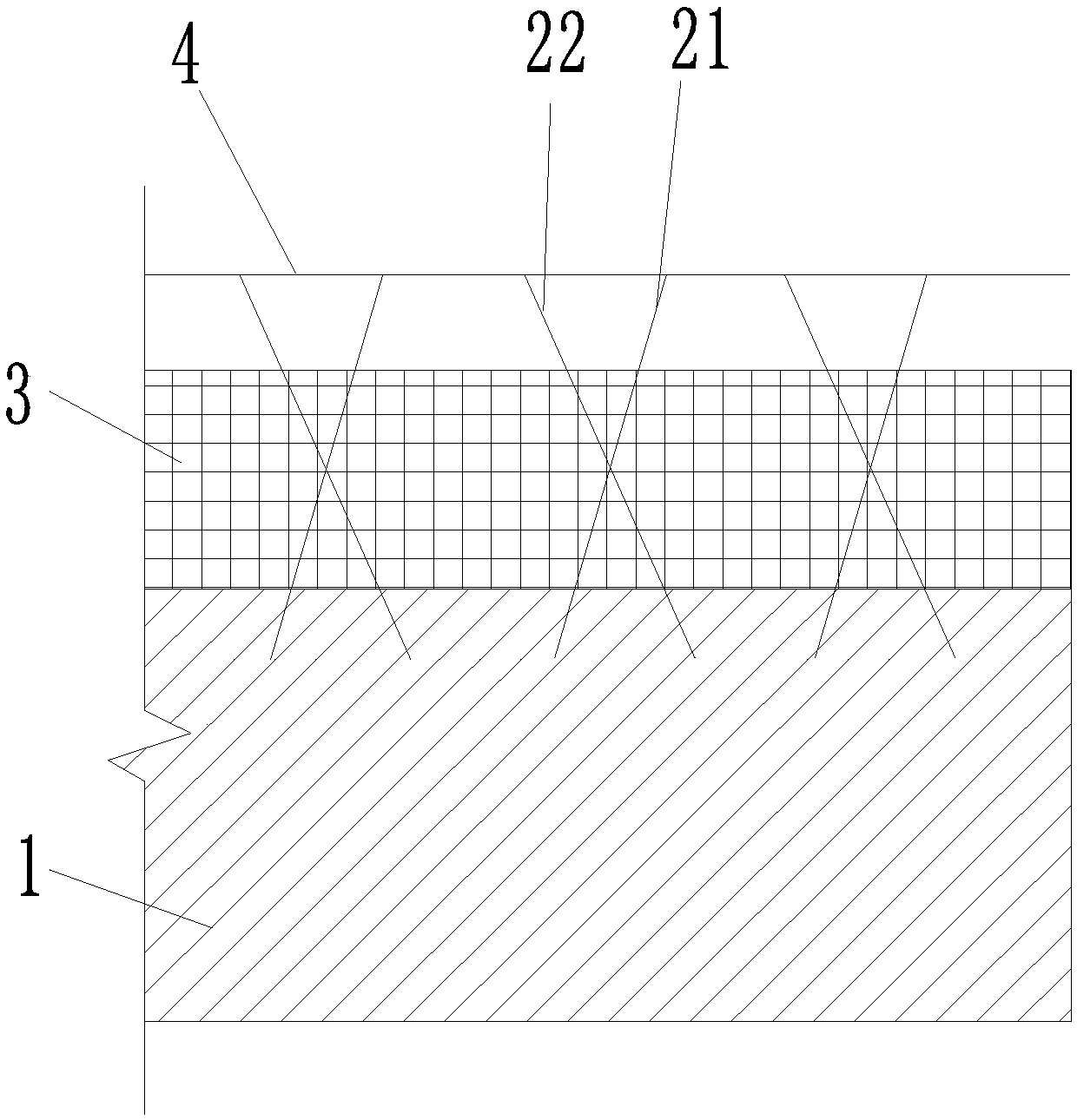

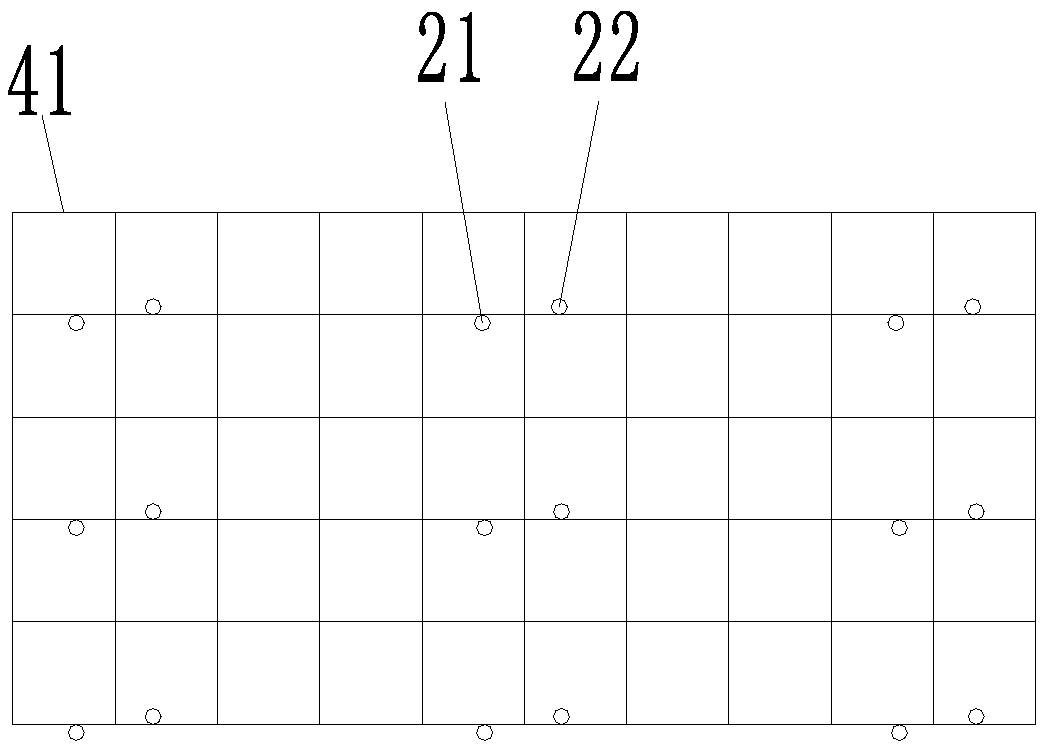

[0032] Such as figure 1 and image 3 As shown, a filling block for pouring, which includes a block body 1, a thermal insulation layer 3 is closely attached to one side of the block body 1, and a first steel mesh 4 is provided on one side of the thermal insulation layer 3, and further , the first steel mesh sheet 4 is connected by a number of criss-cross steel bars 41, and a number of connectors are connected to the first steel mesh sheet 4. More closely, the connectors include first abdominal wires 21 and second abdominal wires 22 , the first abdominal wire 21 and the second abdominal wire 22 intersect each other and penetrate the insulation layer 3 to extend and be fixed in the block body 1 . Advantageously, by setting the first abdominal wire 21 and the second abdominal wire 22 in an interlaced form, the fixation of the thermal insulation layer 3 is more firm, and the thermal insulation layer 3 and the connecting piece will not appear relative displacement phenomenon, which...

Embodiment 2

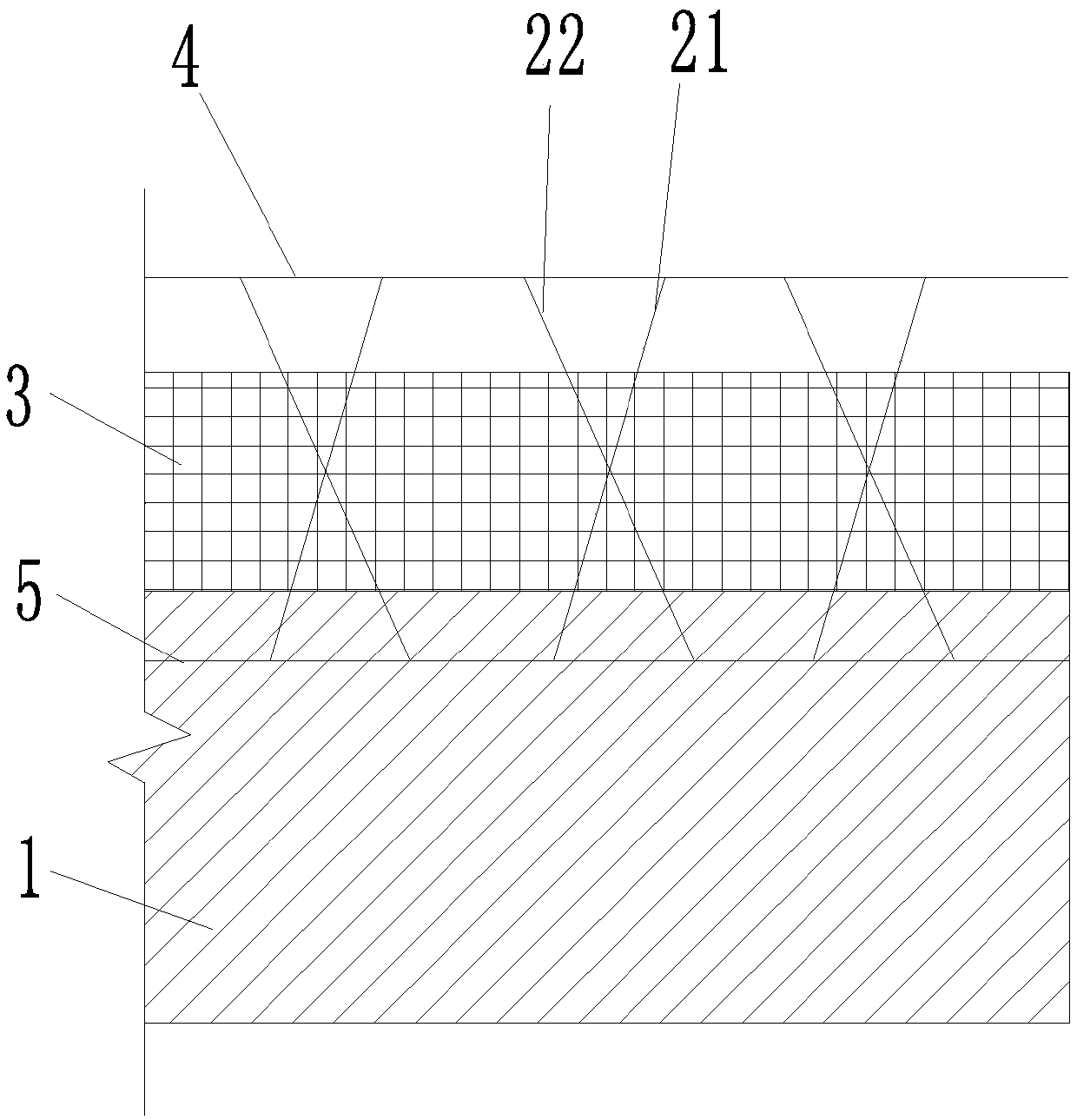

[0036] Such as figure 2 As shown, the other structures are the same as those in Embodiment 1, except that a second reinforcement mesh 5 is provided inside the block body 1, and the second reinforcement mesh 5 is connected with the first abdominal wire 21 and the second abdominal wire respectively. 22 phase fixed connections.

[0037] A construction method for filling blocks for pouring is as follows:

[0038] Such as Figure 4As shown, when it is used for pre-filled block walls, according to the requirements of the drawings, the wall is first built with filling blocks at the corresponding positions, and several first tie bars 7 are bound during the masonry process. Advantageously, In order to improve the tight connection between the filled block wall and the cast-in-place concrete wall, both ends of the first tie bar 7 have elbow shapes. Fixedly install the first steel mesh sheet 4 and the insulation layer 3 that are unified with the filling block, paste the reinforcing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com