Construction method of heat insulation temperature reduction type asphalt concrete wearing layer

A technology of asphalt concrete and construction method, which is applied to the coagulation pavement, roads, pavement details and other directions of on-site paving, can solve problems such as occupation of land resources and environmental pollution, save natural resources, reduce thermal energy accumulation, and reduce road surface. effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below.

[0062] A construction method for a heat-resistant and cooling-type asphalt concrete wear course, comprising the selection of raw materials, the design of the material mix ratio and the construction method of the wear course cover, including the following steps:

[0063] (1) Selection of raw materials

[0064] Asphalt: Zhonghai AH-70# asphalt is selected as the base asphalt, and high-viscosity modified emulsified 70# asphalt is used as the adhesive layer asphalt;

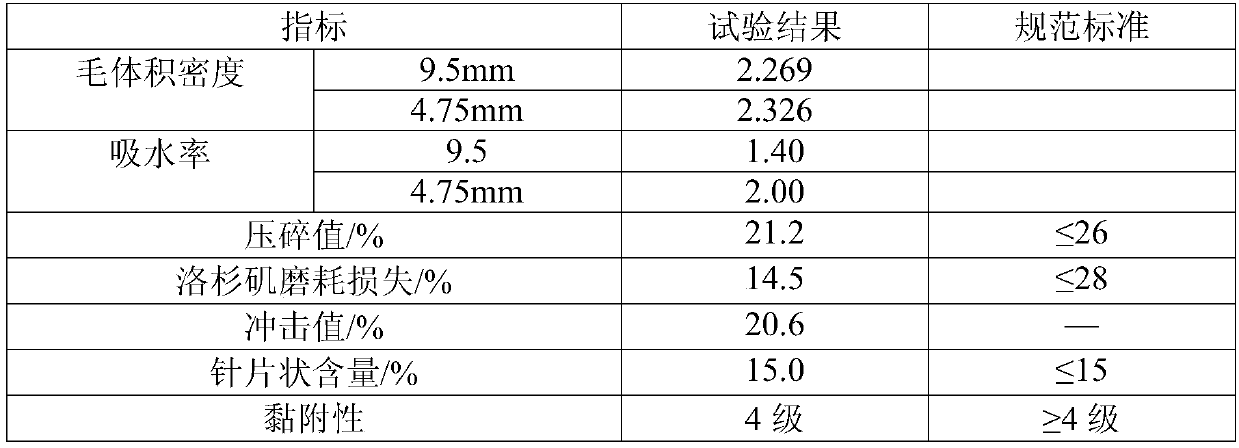

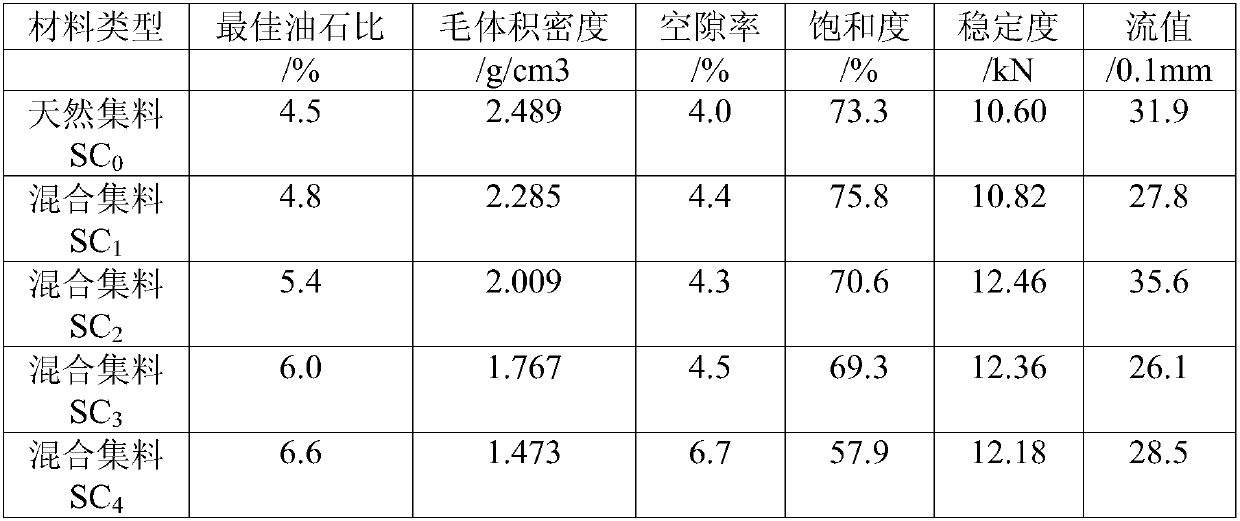

[0065] Waste ceramic recycled materials: the particle size requirements are 4.75mm and 9.5mm, and partly replace natural mineral materials (such as crushed stone materials);

[0066] Use an impact or hammer crusher to process and process waste ceramic products to obtain two grades of recycled coarse aggregate with a particle size of 4.75mm and 9.5mm, and store them for later use to replace part of the coarse aggregate in asphalt concrete (such as gravel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com