Preparation method of carbon nanoparticle solution and application of carbon nanoparticle solution in nickel coating

A carbon nanoparticle and solution technology, applied in the field of carbon nanoparticle solution preparation, can solve the problems of high preparation cost and immature technology application, and achieve the effects of improved corrosion resistance, low cost and high feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

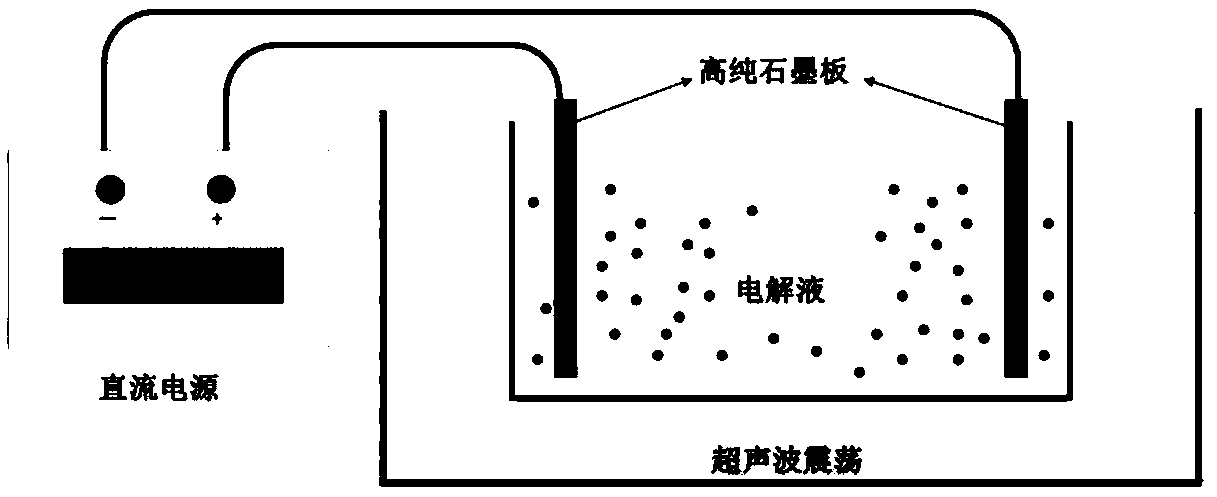

[0033] A method for preparing a carbon nanoparticle solution, comprising the following steps:

[0034] Step 1, prepare electrolyte, the solute of the electrolyte is 0.15~0.25mol / L HNO 3 , 0.08~0.12mol / L (CH 2 Oh) 2, 0.15~0.25g / L C 12 h 25 NaSO 4 , the solvent is deionized water;

[0035] Step 2, take two high-purity graphite plates, clean them with deionized water, fix them with crocodile clips with copper rods, and fix them on the fixtures in parallel and vertically, and then put the fixtures into the electrolyte tank In the container, adjust the height of the fixture so that the graphite plate is immersed in the electrode solution, and then put the device into the ultrasonic instrument. After fixing, connect the positive and negative poles of the DC power supply to the copper rods respectively. After energizing and reacting, a carbon nanoparticle solution is obtained. ;

[0036] Wherein, the specification of the high-purity graphite plate in step 2 is 100*50*2mm.

[...

Embodiment 2

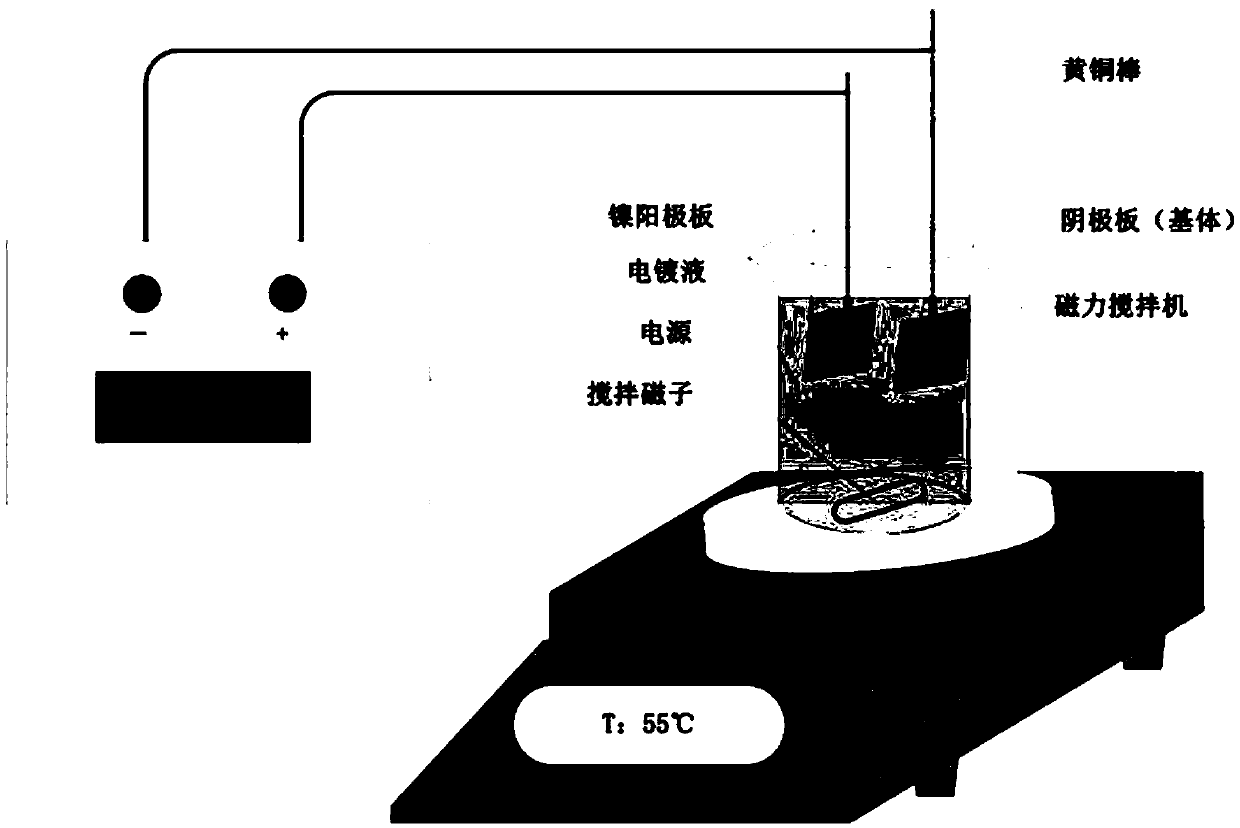

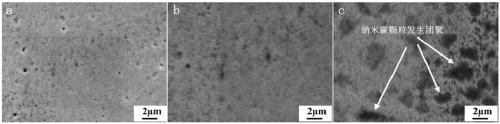

[0040] Add carbon nanoparticle solutions with concentrations of 5mL / L, 10mL / L, 20mL / L, 30mL / L, and 50mL / L to the nickel plating solution respectively, and the prepared samples are recorded as the second sample, the third sample, and the fourth sample respectively. sample, fifth sample and sixth sample. Tested with the sample prepared above, its performance was analyzed, and 6 samples were obtained, and the performance analysis and comparison of these 6 samples were carried out. The results are as follows: Figure 3-6 shown.

[0041] It can be seen from the figure that when the concentration of the carbon nanoparticle solution is 10mL / L, the hardness, friction and wear resistance, and corrosion resistance of the coating are significantly improved, but the concentration of the carbon nanoparticle solution in the electroplating solution exceeds 10mL / L It will lead to the loose structure of the nickel coating, which will lead to the decline of its comprehensive performance. When...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com