Pre-melting slag for high-temperature alloy electroslag remelting

An electroslag remelting and superalloy technology, applied in the field of superalloy smelting, can solve the problems of Zr element content difference, Zr element burning loss, difficulty, etc., to reduce content inhomogeneity, improve composition uniformity, and improve surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

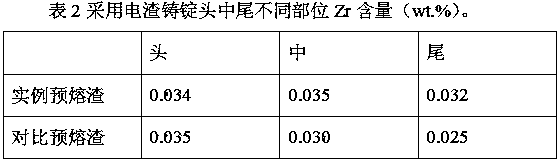

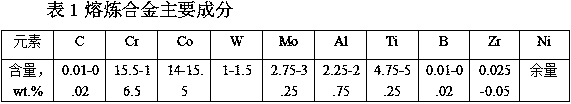

[0020] Electroslag remelting of GH4720Li alloy.

[0021] This example uses the pre-melted slag of the present invention and the comparative pre-melted slag to carry out electroslag melting of the Zr-containing superalloy GH4720Li alloy. The main components of GH4720Li are shown in Table 1, and the electrodes used are those cast by vacuum induction melting. The pre-melted slag used is configured according to the predetermined composition, and the pre-melted treatment is carried out after mixing evenly, and the FeO and SiO are reduced after treatment. 2 content while reducing the water content. The slag after pre-melting treatment is sealed and stored to prevent moisture absorption. The Zr content in the sensing electrode is 0.035 (wt.%).

[0022]

[0023] The pre-slag of embodiment 1:

[0024] CaF 2 :50%, Al 2 o 3 :20%, CaO: 20%, MgO: 3%, TiO 2 :3%, ZrO 2 : 3%, impurity: 1%.

[0025] Compared with pre-slag:

[0026] CaF 2 :50%, Al 2 o 3 : 23%, CaO: 20%, MgO: 3%...

Embodiment 2

[0031] Electroslag remelting of GH4738 alloy.

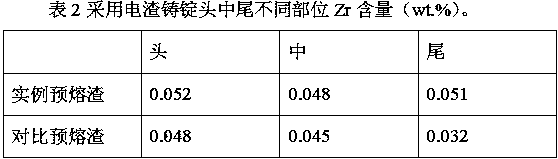

[0032] This example uses the pre-melted slag of the present invention and the comparative pre-melted slag to carry out electroslag melting of the Zr-containing superalloy GH4738 alloy. The main components of GH4738 are shown in Table 1, and the electrodes used are those cast by vacuum induction melting. The pre-melted slag used is configured according to the predetermined composition, and the pre-melted treatment is carried out after mixing evenly, and the FeO and SiO are reduced after treatment. 2 content while reducing the water content. The slag after pre-melting treatment is sealed and stored to prevent moisture absorption. The Zr content in the sensing electrode is 0.05 (wt.%).

[0033]

[0034] Embodiment 2 pre-melted slag:

[0035] CaF 2 :50%, Al 2 o 3 : 20%, CaO: 18%, MgO: 3%, TiO 2 :3%, ZrO 2 : 5%, impurities: 1%.

[0036] Compared with pre-slag:

[0037] CaF 2 :50%, Al 2 o 3 : 23%, CaO: 20%, MgO: 3%, Ti...

Embodiment 3

[0042] CaF 2 : 60%; Al 2 o 3 : 25%; CaO: 10%; MgO: 1%;

[0043] TiO 2 : 1; ZrO 2 : 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com