Low cost and high performance binding material for roads and preparation method thereof

A high-performance, low-cost technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of asphalt waste environmental pollution recycling, etc., to improve the softening point and save resources , Improve the effect of high temperature stability and viscoelasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

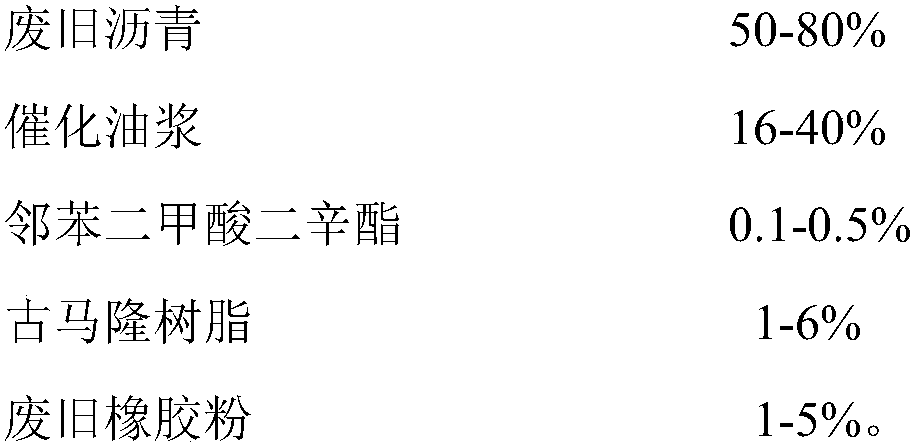

[0033] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0034]

[0035] The preparation method of the low-cost high-performance road binder comprises the following steps: first heating the waste asphalt to a temperature of 135°C, and then adding catalytic oil slurry, dioctyl phthalate and coumarone resin together with the waste asphalt Mix and stir for 8 minutes, and keep the temperature of the mixture at 135°C, then pour it into the high-speed shearing equipment together with the waste rubber powder, and perform high-speed circulation shearing at 135°C for 15 minutes, so that the waste rubber powder and the mixture are completely mixed Melt to form a swollen structure of the mixture. Then, the mixture is heated to 150°C and ventilated and stirred for 250 minutes to further remove volatile components in the mixture and improve its high-temperature stability and aging resista...

Embodiment 2

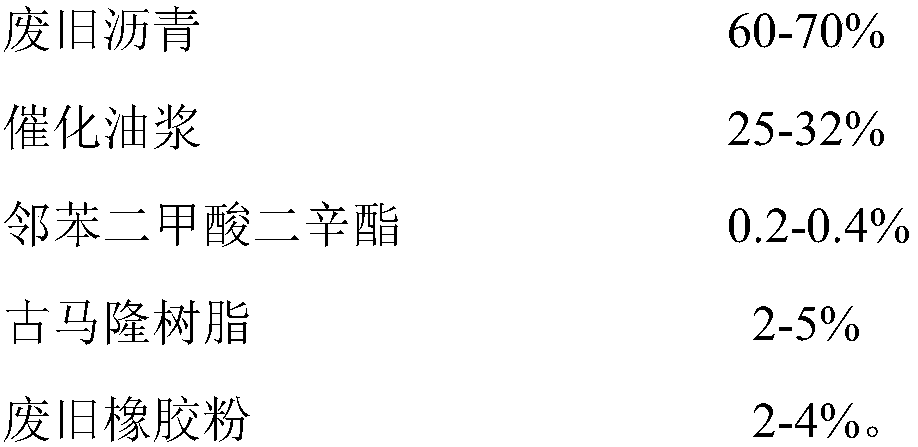

[0037] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0038]

[0039] The preparation method of the low-cost high-performance road binder comprises the following steps: first heating the waste asphalt to a temperature of 130°C, and then adding catalytic oil slurry, dioctyl phthalate and coumarone resin together with the waste asphalt Mix and stir for 8 minutes, and keep the temperature of the mixture at 130°C, then pour it into the high-speed shearing equipment together with the waste rubber powder, and perform high-speed circulation shearing at 130°C for 15 minutes, so that the waste rubber powder and the mixture are completely mixed Melt to form a swollen structure of the mixture. Then, the mixture is heated to 140°C and ventilated and stirred for 250 minutes to further remove the volatile components in the mixture and improve its high-temperature stability and aging res...

Embodiment 3

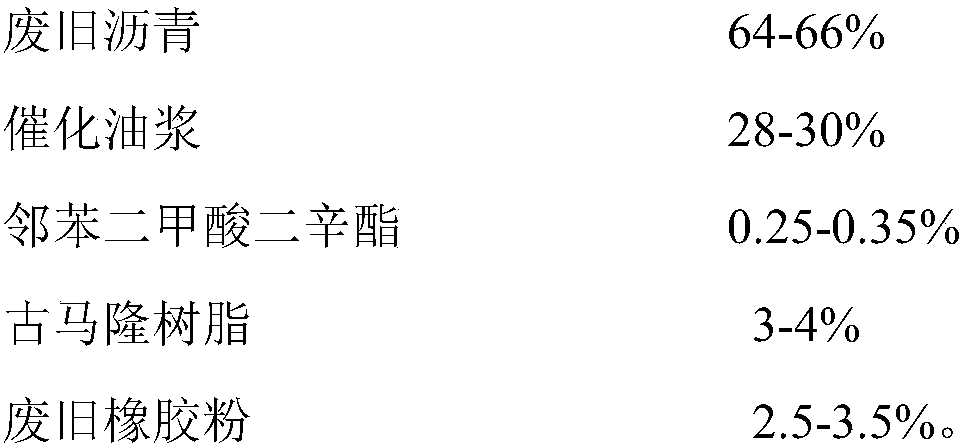

[0041] Taking the production of 500 grams of the product of the present invention as an example, the raw materials used and the proportioning thereof are:

[0042]

[0043] The preparation method of the low-cost high-performance road binder comprises the following steps: first heating the waste asphalt to a temperature of 140°C, and then adding catalytic oil slurry, dioctyl phthalate and coumarone resin together with the waste asphalt Mix and stir for 8 minutes, and keep the temperature of the mixture at 140°C, then pour it into the high-speed shearing equipment together with the waste rubber powder, and perform high-speed circulation shearing at 140°C for 15 minutes, so that the waste rubber powder and the mixture are completely mixed Melt to form a swollen structure of the mixture. Then, the mixture is heated to 150° C. and ventilated and stirred for 240 minutes to further remove the volatile components in the mixture and improve its high-temperature stability and aging r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com