Photocuring anti-doodling ink, and preparation method and anti-doodling coating layer thereof

An anti-graffiti and light-curing technology, applied in the field of material chemistry, can solve the problems of single anti-graffiti technology, high cost and safety risks, and achieve excellent anti-graffiti performance, good anti-graffiti effect, and low surface tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Components:

[0033] Oligomer

Polyester acrylate (liquid) 15g

active monomer

Isobornyl Acrylate (Liquid) 20g

1-Hydroxycyclohexyl phenyl ketone 3g

Trimethylbenzoyl diphenylphosphine oxide 2g

Erucamide 5g

Auxiliary

(Defoamer, liquid) 1g

(leveling agent, liquid) 0.5g

Titanium dioxide 25g

filler

[0034] 2) Preparation method: under normal temperature and pressure conditions, in a container, after fully stirring and mixing the oligomers, active monomers and additives in the above components, slowly add them under stirring at 100-200 rpm After feeding the remaining raw materials, disperse for 30 minutes at a speed of 1000-1500 rpm until all materials are fully mixed, dissolved and evenly dispersed. Use a three-roll machine to grind the dispersed slurry twice to a fineness of ...

Embodiment 2

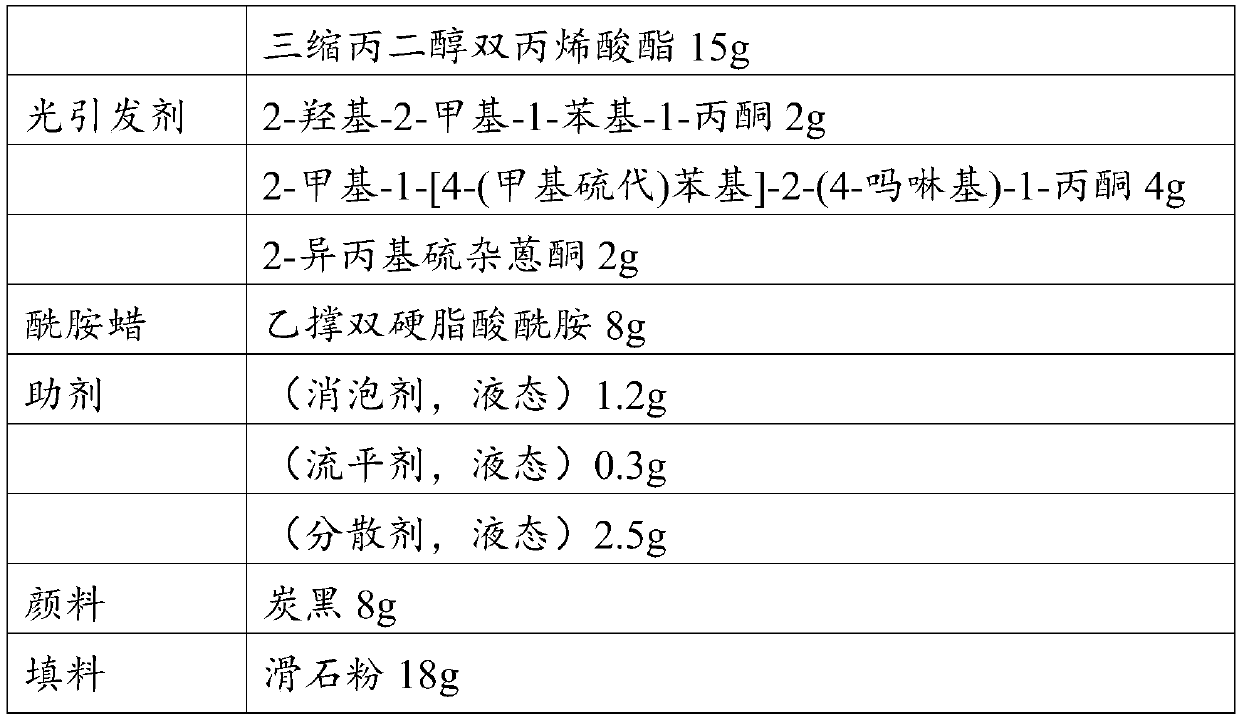

[0037] 1) Components

[0038]

[0039]

[0040]2) Preparation method: under normal temperature and pressure conditions, in a container, after fully stirring and mixing the oligomers, active monomers and additives in the above components, slowly add the remaining Raw materials, after feeding, disperse for 30 minutes at a speed of 1000-1500 rpm until all materials are fully mixed, dissolved and dispersed evenly. Grinding the dispersed slurry four times with a three-roll machine until the fineness is less than 5 microns, so as to obtain a UV curable black ink.

[0041] The test found that the ink can be cured rapidly under UV, and can form a black ink coating with low surface tension, and has remarkable anti-graffiti performance.

[0042] In this embodiment, by adding different photoinitiators, the ink can trigger free radical reactions for different wavelengths of ultraviolet light to cause cross-linking and curing, so that due to the influence of the penetration depth of...

Embodiment 3

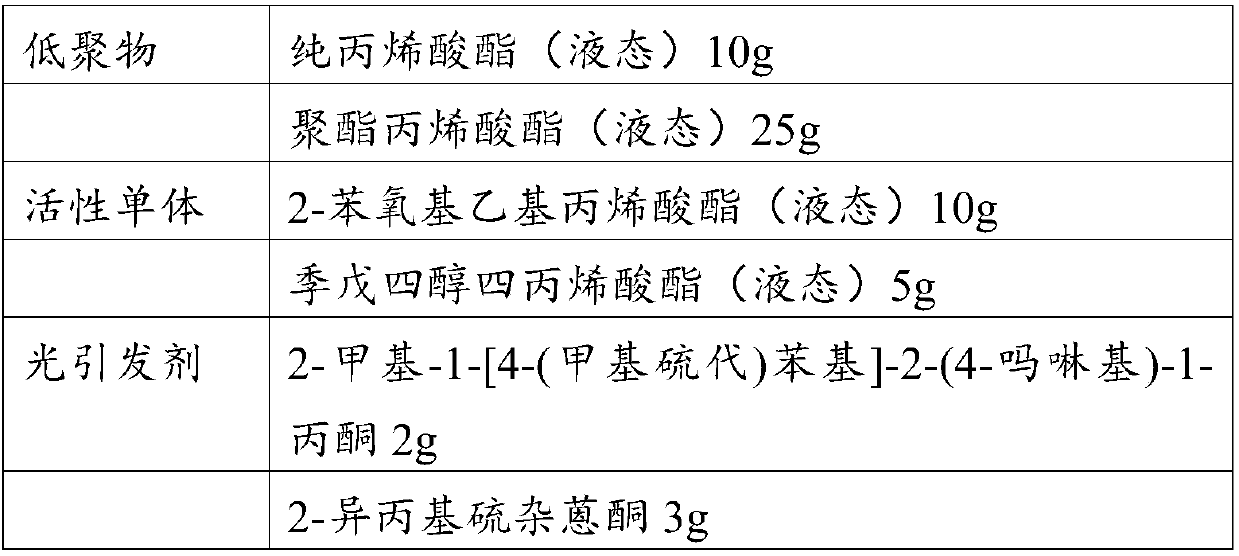

[0044] 1) Components

[0045]

[0046]

[0047] 2) Preparation method: under normal temperature and pressure conditions, in a container, after fully stirring and mixing the oligomers, active monomers and additives except the thixotropic agent in the above components, at 100-200 rpm Slowly add the remaining raw materials at the speed of 1000-1500 rpm for 30 minutes until all the materials are fully mixed, dissolved and dispersed evenly after feeding all the raw materials. Grinding the dispersed slurry four times with a three-roll machine until the fineness is less than 5 microns to obtain a UV curable low surface tension anti-graffiti red ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com