Rubber gasket used for pot bearing and capable of making force measurement precise and pot bearing thereof

A technology of rubber pads and supports, applied in the direction of measuring force, measuring devices, instruments, etc., can solve the problems of bias, rotational bias, etc., and achieve the effect of reducing manufacturing cost, solving local bias, and reducing structural strength allowance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]The raw material of the rubber pad of this embodiment includes 100 parts of chloroprene rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 20 parts of carbon black, 0.5 part of accelerator NA-22, 2 parts of accelerator DM, 2 parts of antioxidant 4010NA, 2 parts of anti-aging agent ODA, 2 parts of paraffin, 15 parts of plasticizer DOP, 4 parts of magnesium oxide, 2 parts of anti-scorch agent CR-X, 2 parts of HVA-2.

[0036] Add the synthetic rubber and the above-mentioned additives into the internal mixer for mixing, then preform, and then install the mold for vulcanization. The vulcanization temperature is 140 ° C, the vulcanization compressive stress is 15 MPa, and the vulcanization time is 2 to 5 hours. The required size is directly produced. rubber mat. Wherein, the IRHD hardness of the rubber pad prepared in this embodiment is 30, the tensile strength is 20 MPa, and the elongation at break is 650%.

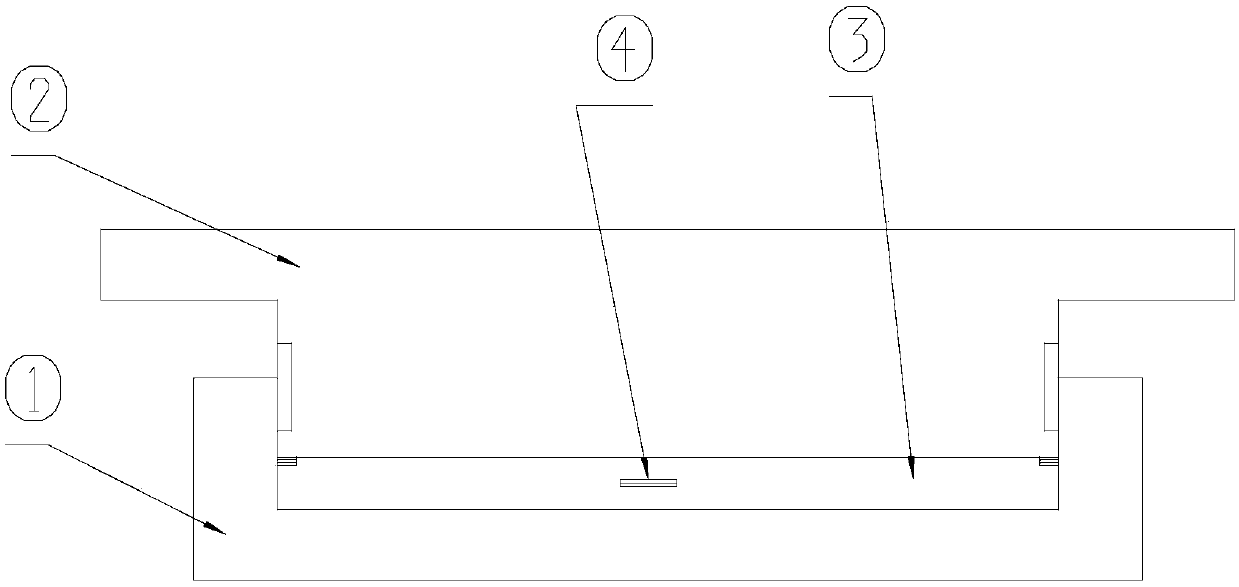

[0037] The above-mentioned rubber pad is assembled with the b...

Embodiment 2

[0039] The raw materials of the rubber pad in this embodiment include 100 parts of natural rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 20 parts of carbon black, 1 part of accelerator DM, 2 parts of accelerator CZ, 2 parts of anti-aging agent 4010NA, 2 parts of anti-aging agent RD 2 parts, 2 parts paraffin, 15 parts engine oil, 1 part sulfur.

[0040] Add natural rubber and the above-mentioned additives into the internal mixer for mixing, then preform, and then mold and vulcanize. The vulcanization temperature is 140°C, the vulcanization compressive stress is 15MPa, and the vulcanization time is 2 to 5 hours. The required size is directly produced. rubber mat. Wherein, the IRHD hardness of the rubber pad prepared in this embodiment is 32, the tensile strength is 23 MPa, and the elongation at break is 660%.

[0041] The above-mentioned rubber pad is assembled with the bottom basin 1, the middle steel plate 2 and the compressive stress sensor 4. The rubber pad 3 is a...

Embodiment 3

[0043] The raw materials of the rubber pad in this embodiment include 100 parts of EPDM rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 20 parts of carbon black, 4 parts of accelerator EM-35, 1 part of anti-aging agent 4010NA, and 1 part of anti-aging agent RD. 50 parts of paraffin oil, 1 part of sulfur.

[0044] Add EPDM rubber and the above-mentioned additives into an internal mixer for mixing, then preform, and then mold and vulcanize. The vulcanization temperature is 140 ° C, the vulcanization compressive stress is 15 MPa, and the vulcanization time is 2 to 5 hours. Rubber pads of the desired size. Wherein, the IRHD hardness of the rubber pad prepared in this embodiment is 29, the tensile strength is 21 MPa, and the elongation at break is 655%.

[0045] The above-mentioned rubber pad is assembled with the bottom basin 1, the middle steel plate 2 and the compressive stress sensor 4. The rubber pad 3 is arranged between the bottom basin 1 and the middle steel plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com