Aminated fluorinated graphene and preparation method thereof

A fluorinated graphene, amination technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problem that fluorinated graphene is not easy to modify, limit the application of fluorinated graphene, limit modification and application, etc. problems, to achieve the effect of short cycle, low preparation cost and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0030] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

[0031] Instruments and Equipment

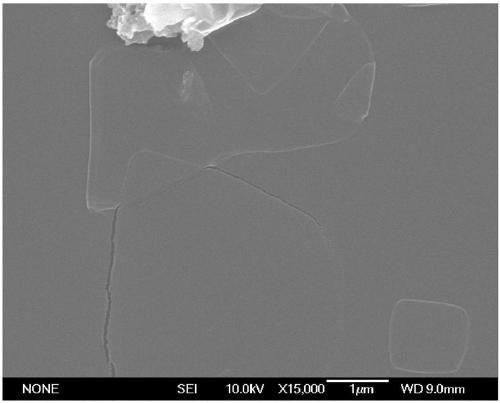

[0032] The electron micrographs of this application were completed by the Phenom G2Pro desktop scanning electron microscope of Phenom-world company in the Netherlands.

Embodiment 1

[0034] Weigh 100 mg of graphene fluoride and 500 mg of ammonium chloride, grind them thoroughly with a mortar, pour them into an alumina crucible, place them in a tube furnace, raise the temperature to 300°C, keep it for 2 hours, and cool down naturally.

[0035] The above product was collected, dispersed into a mixed solution of 2-methylpyrrolidone and distilled water at a volume ratio of 1:1, filtered with suction, and washed three times with 2-methylpyrrolidone and distilled water respectively. The sample after suction filtration and washing was freeze-dried for 6 hours to obtain aminated fluorinated graphene powder.

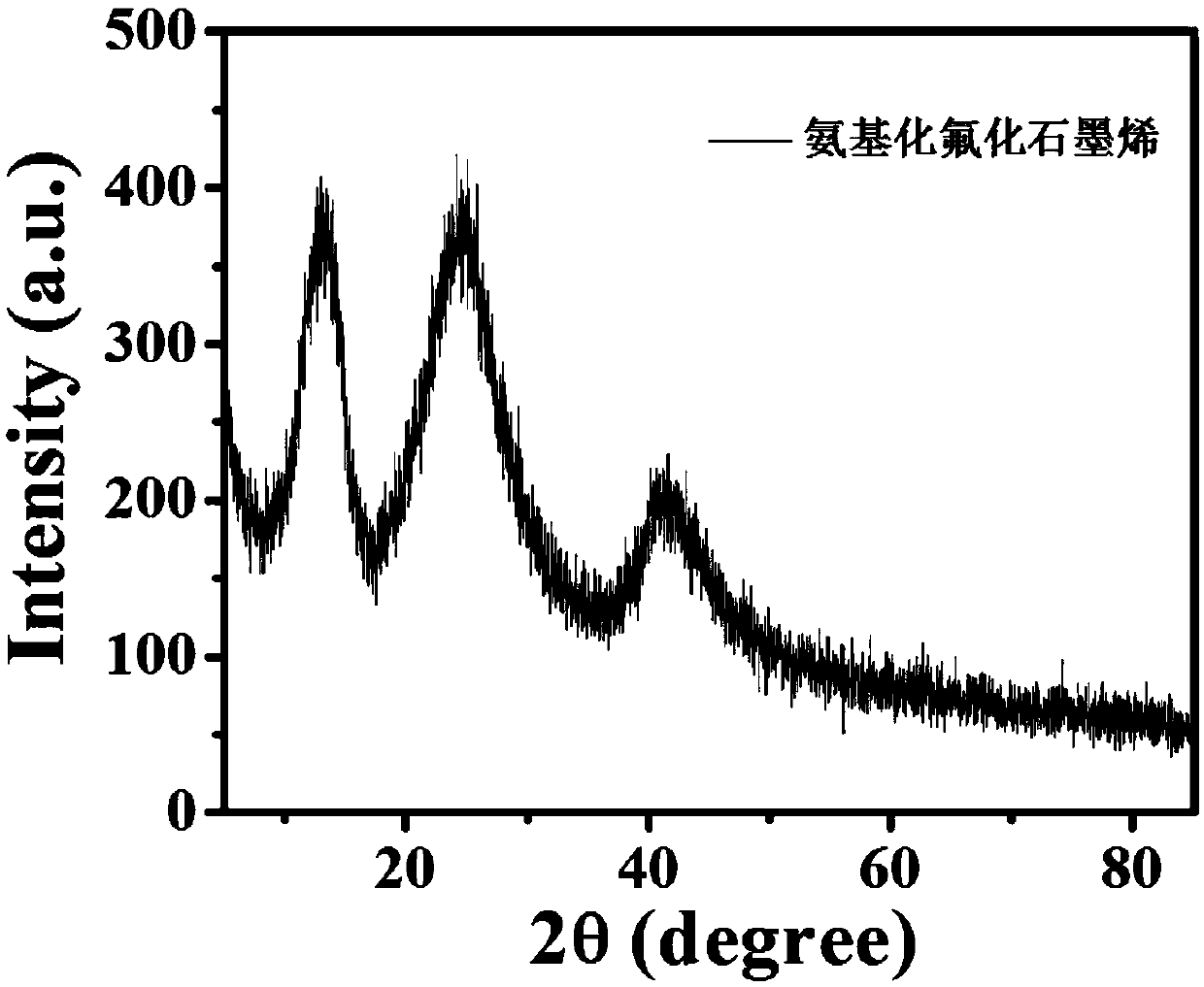

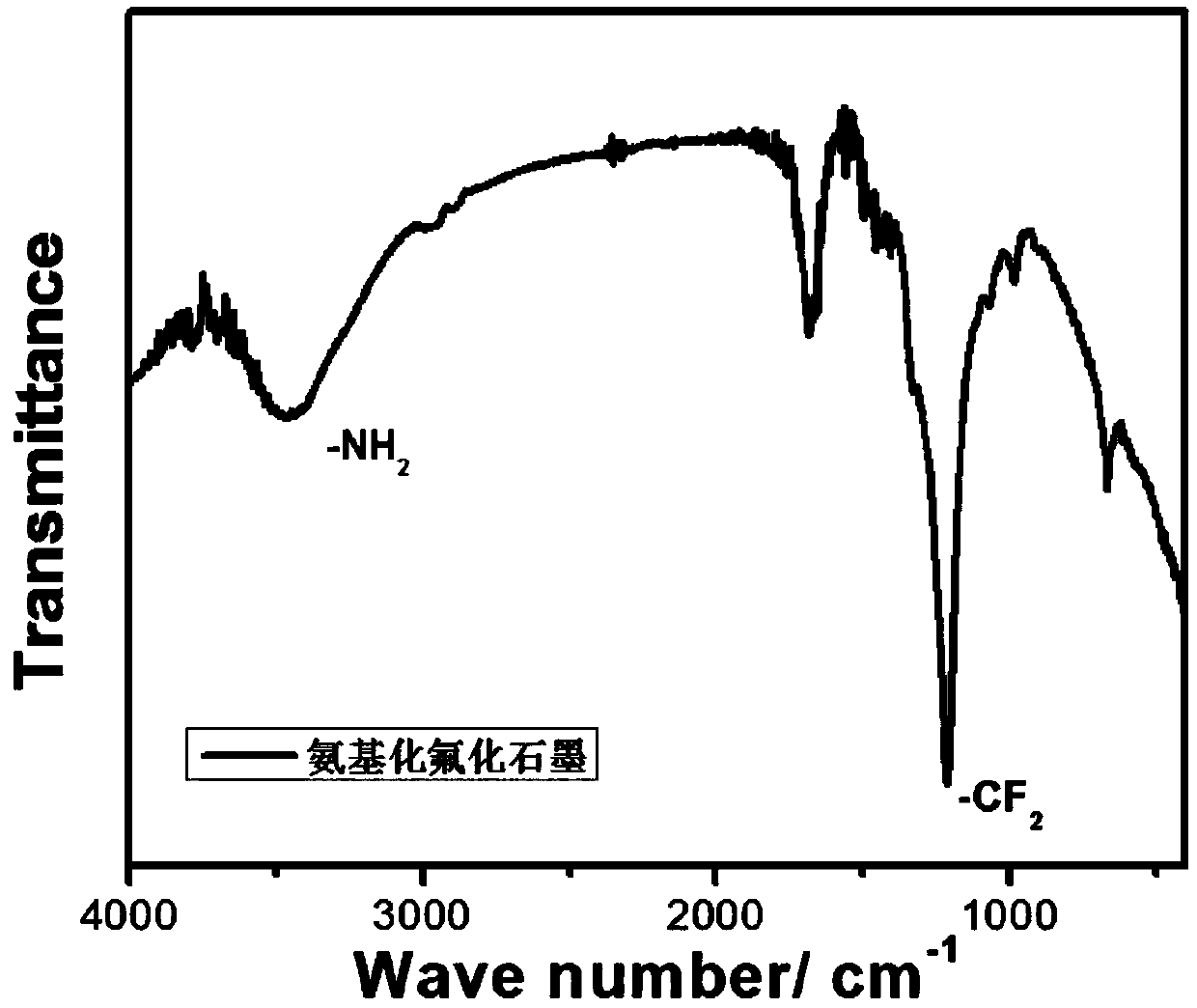

[0036] figure 1 It is the powder diffraction pattern of the aminated fluorinated graphene of Example 1 of the present invention. From figure 1 It can be seen from the figure that the aminated fluorinated graphene has three typical fluorinated graphene diffraction peaks, the interlayer spacing is about 0.37nm by calculation, and the number of layers is betwe...

Embodiment 2

[0041] Weigh 100 mg fluorinated graphene and 1000 mg ammonium carbonate, grind them thoroughly with a mortar, pour them into an alumina crucible, place them in a tube furnace, raise the temperature to 400 °C, keep it for 1 hour, and cool down naturally.

[0042] The above product was collected, dispersed into a mixed solution of nitrogen-nitrogen dimethylformamide and distilled water with a volume ratio of 1:2, filtered with suction, and washed three times with nitrogen-nitrogen dimethylformamide and distilled water respectively. The sample after suction filtration and washing was freeze-dried for 12 hours to obtain aminated fluorinated graphene powder.

[0043] Figure 5 is the atomic content of fluorinated graphene before and after amination treatment in Example 2 of the present invention. From Figure 5 It can be seen from the figure that the content of nitrogen in aminated fluorinated graphene is 12.93%. Compared with Example 1, it can be found that increasing the amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com