Efficient garbage truck for garbage desiccation and garbage unloading method

A technology for transporting vehicles and garbage, which is applied in the field of garbage resource treatment, which can solve the problems of reducing equipment investment costs and garbage drying operation costs, shortening garbage transportation and transshipment time, and inconvenient garbage transportation, so as to reduce garbage drying operation Effects of processing costs, shortening transit time, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

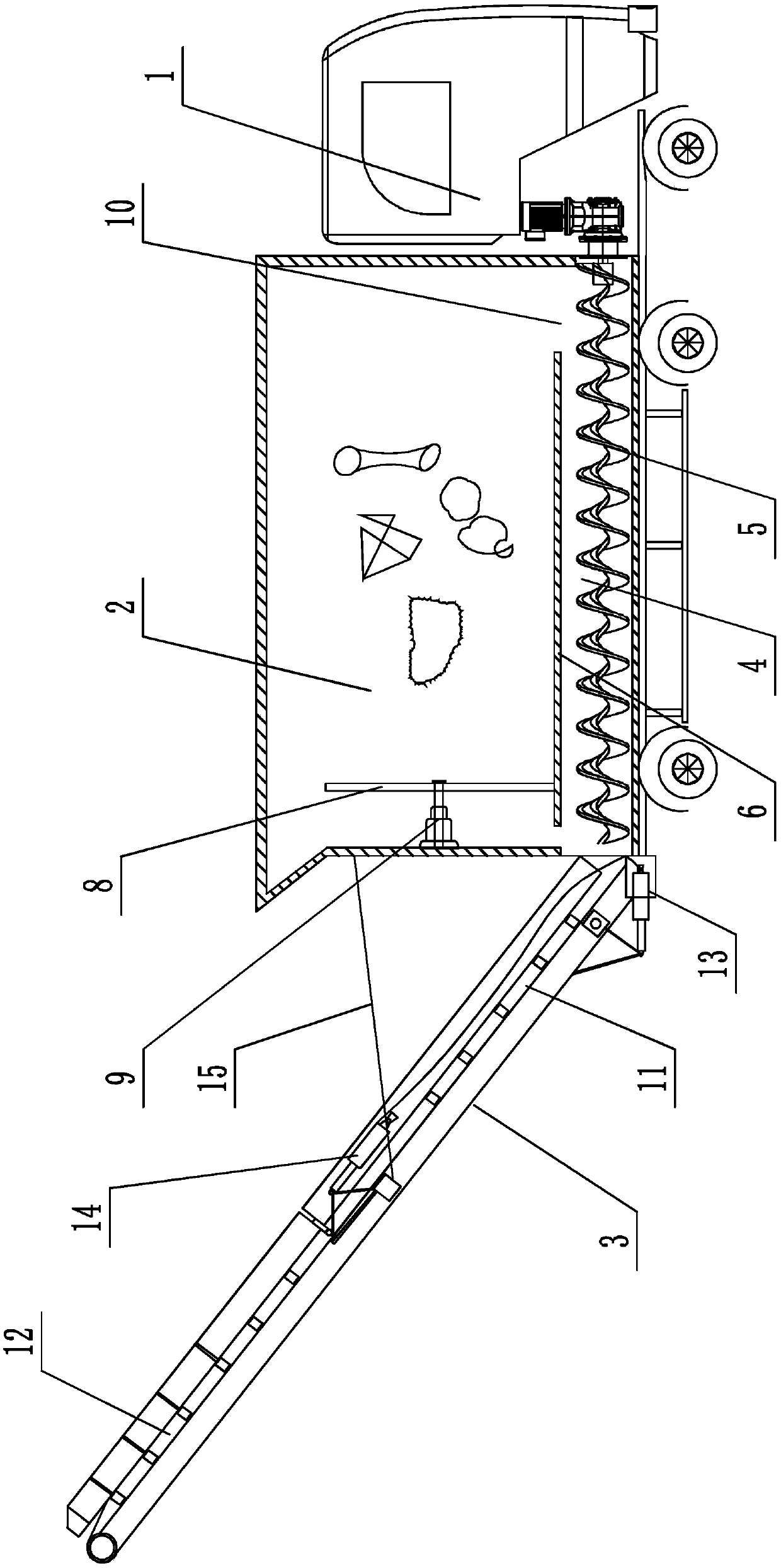

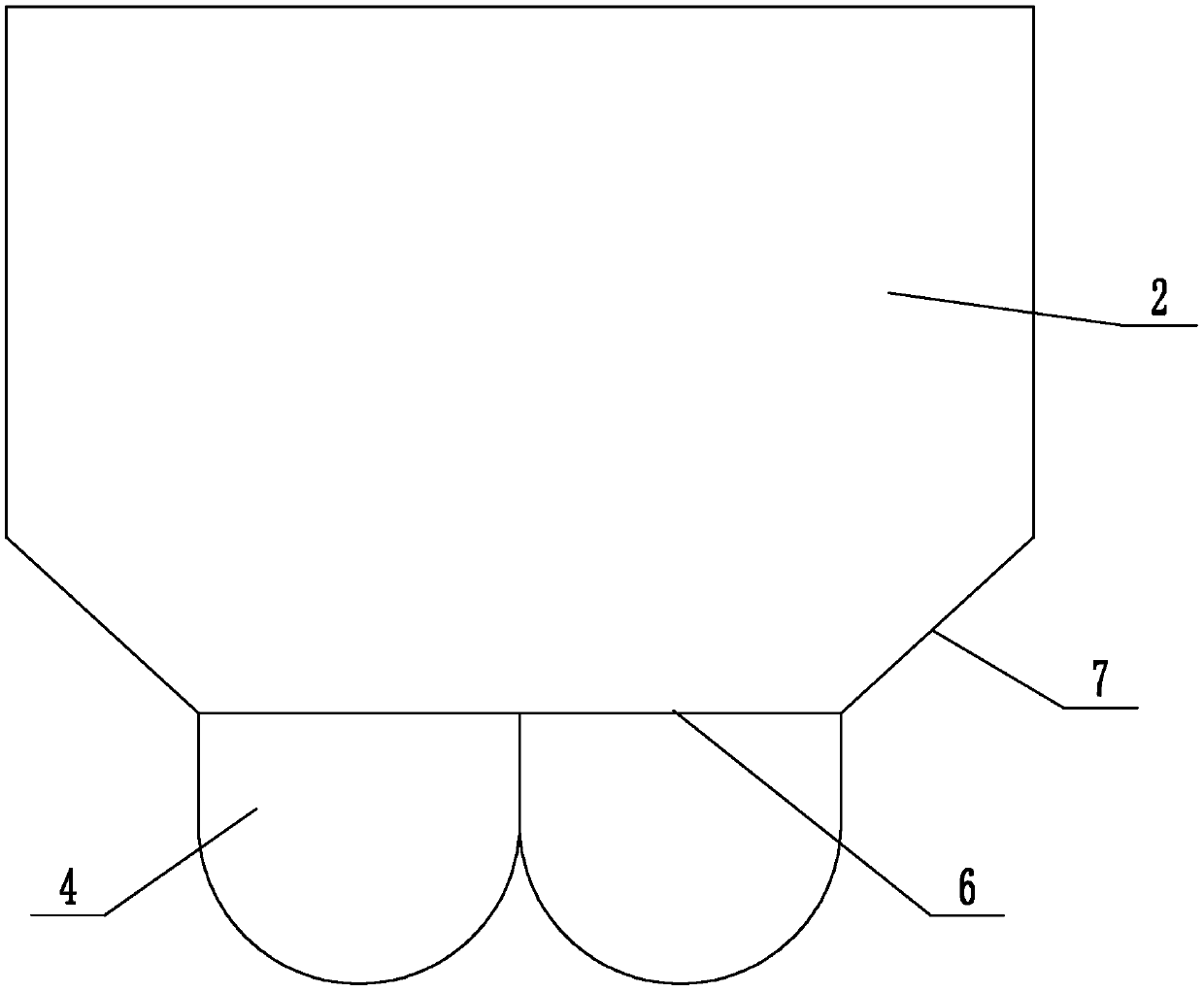

[0026] Embodiment 1: A kind of high-efficiency garbage transport vehicle for garbage drying (see attached figure 1 , attached figure 2), including a car body 1, a carriage 2 is arranged on the car body, a material conveyor belt 3 with adjustable inclination angle is installed at the rear end of the car body, two feeding channels 4 are arranged at the bottom of the car body, and a conveying screw 5 is installed in the feeding channel, and the feeding The rear end of the channel is set correspondingly to the front end of the material conveyor belt. The conveying screw is a double-helix shaftless screw, and the conveying screw is driven by a motor to rotate. The motor is installed on the car body near the front end. The front end of the conveying screw is connected to the output shaft of the motor, and the rear end of the conveying screw is suspended. The bottom of the compartment is provided with a flat loading base plate 6, the width of which is smaller than the width of the ...

Embodiment 2

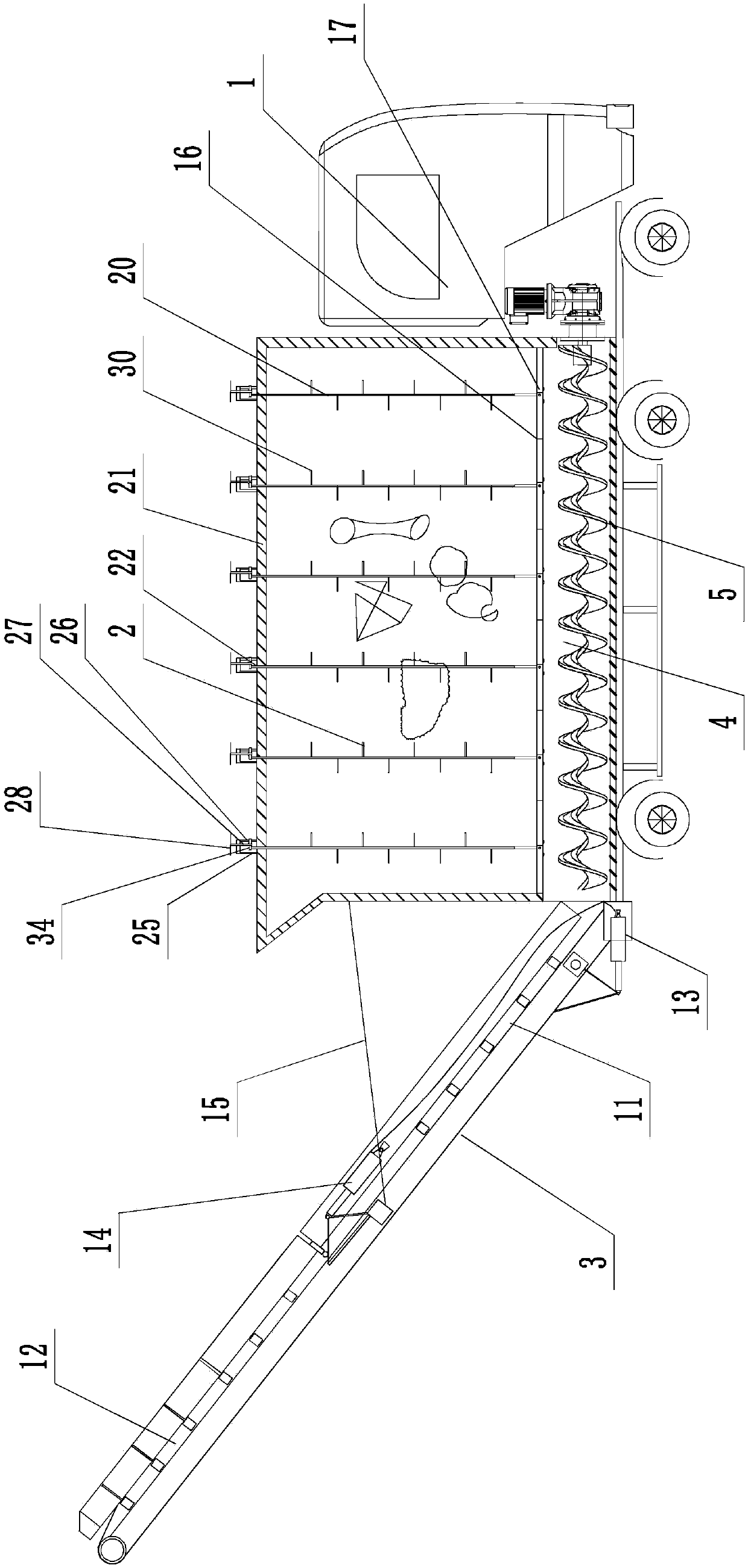

[0028] Embodiment 2: A kind of high-efficiency garbage transport vehicle for garbage drying (see attached image 3 to attach Figure 5 ), its structure is similar to that of Embodiment 1, the main difference is that in the present embodiment, the feed channel is provided with a feed slot 16 arranged towards the top of the carriage, and the feed slot extends from the front end of the feed channel to the rear end of the feed channel. A number of cover plate assemblies 17 are installed at the opening position of the trough hole, and two adjacent cover plate assemblies are attached front and back. The cover plate assembly includes two slide plates 18 hinged together, and a pin shaft 19 is connected between the two slide plates, and a lifting rod is connected to the pin shaft. 20. A top plate 21 is provided on the top of the compartment, and several sockets 22 are arranged on the top plate and the lifting rod one by one. The opposite side walls of the chute hole are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com