Bending device and bending machine

A technology of bending device and bending mechanism, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unsmooth feeding and discharging, difficult assembly line connection, etc., and achieve the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

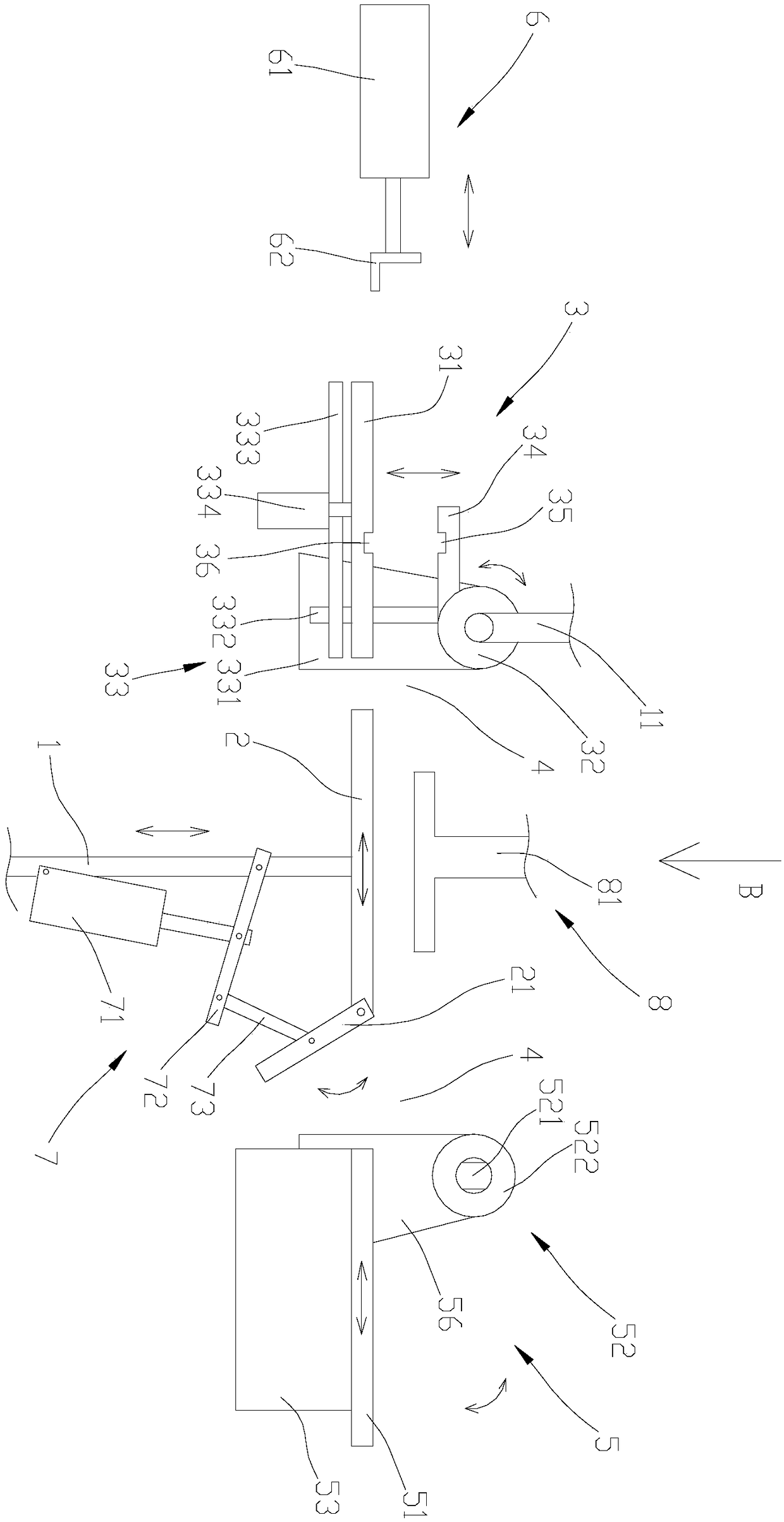

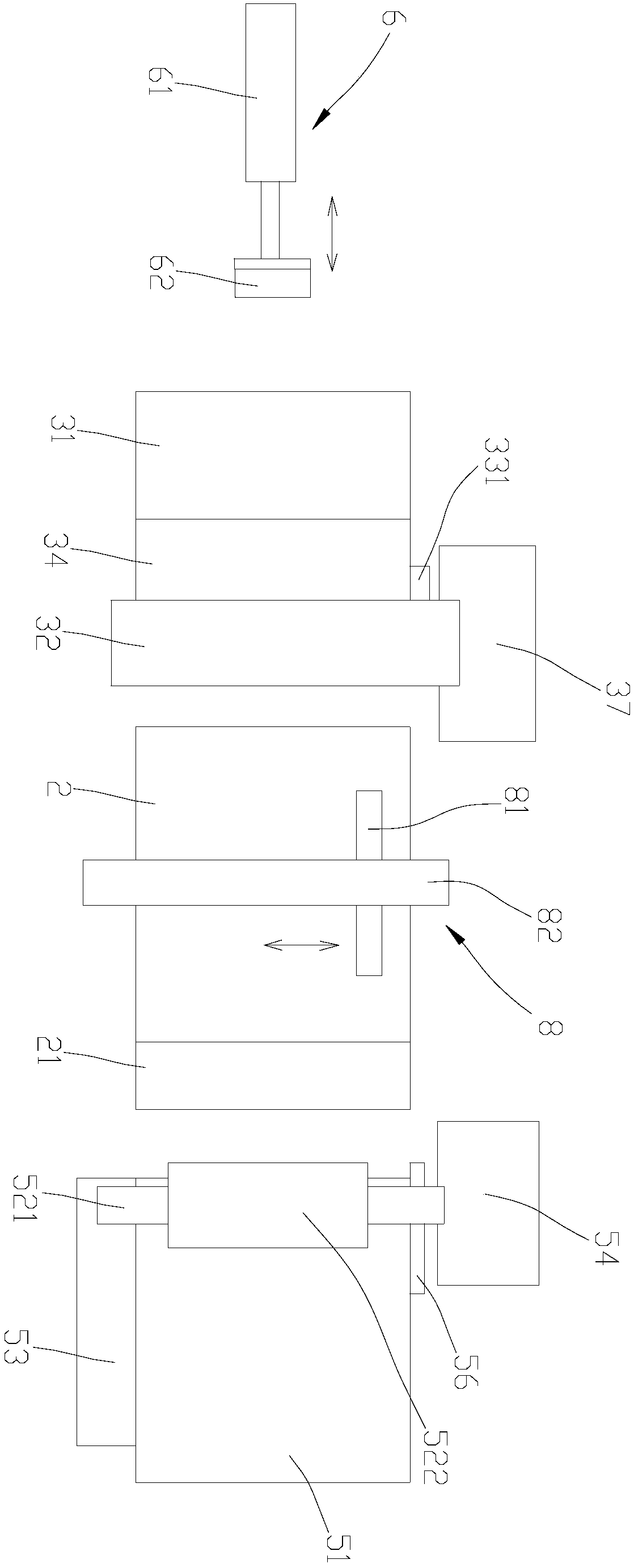

[0023] refer to figure 2 , a bending machine, comprising a base 1, the base 1 is provided with a workpiece platform 2, the front end of the workpiece platform 2 is provided with a first bending mechanism 3, and the first bending mechanism 3 includes a first bending mechanism Bending plate 31 and first turning roller 32, described first bending plate 31 turns and bends with described first turning roller 32 as the center, and described first turning roller 32 extends from one side of described workpiece table 2 to On the other side of the workpiece table 2, between the workpiece table 2 and the first rotating roller 32, a side opening 4 is provided on one side of the workpiece table 2, and the side opening 4 is used for the Describe the use of the material in and out of the workpiece table 2.

[0024] In the present invention, a first bending mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com