Three-head mechanical hand water belt sander

A technology of belt sander and manipulator, which is applied in the direction of belt grinder, grinding machine, grinding feed movement, etc., can solve the problems of low working efficiency of single-head water sander belt machine, achieve quality improvement, improve work efficiency, and structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

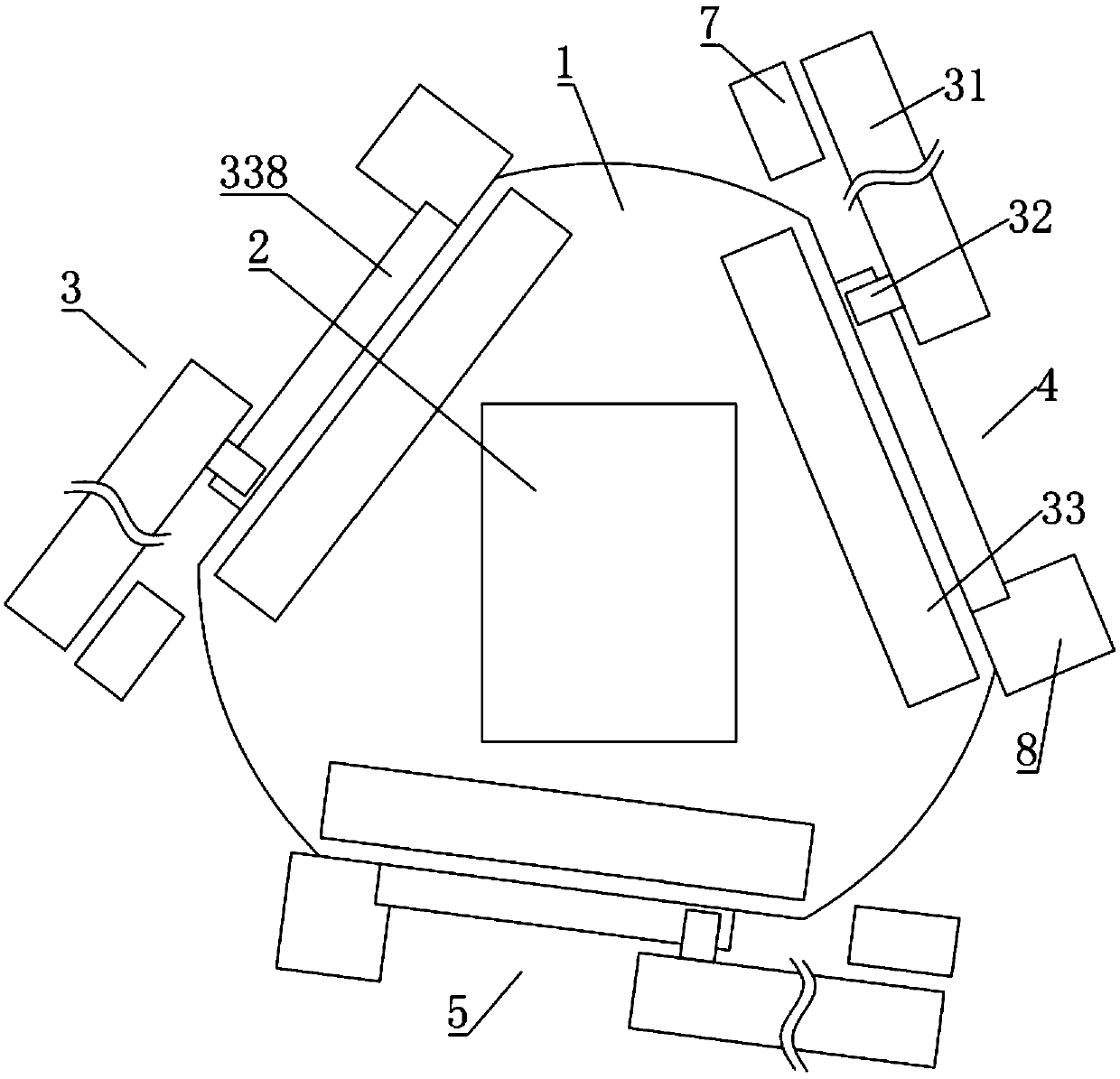

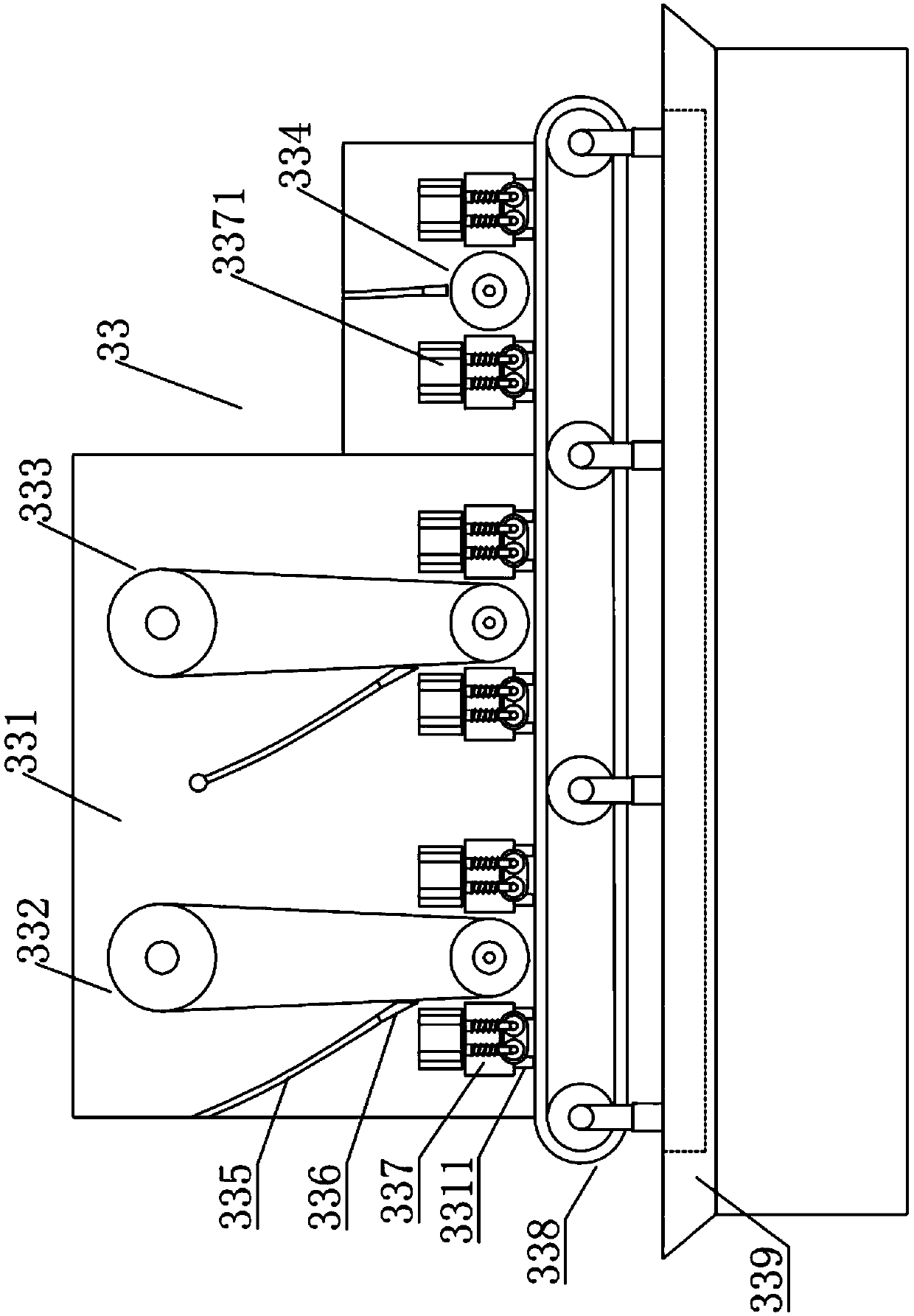

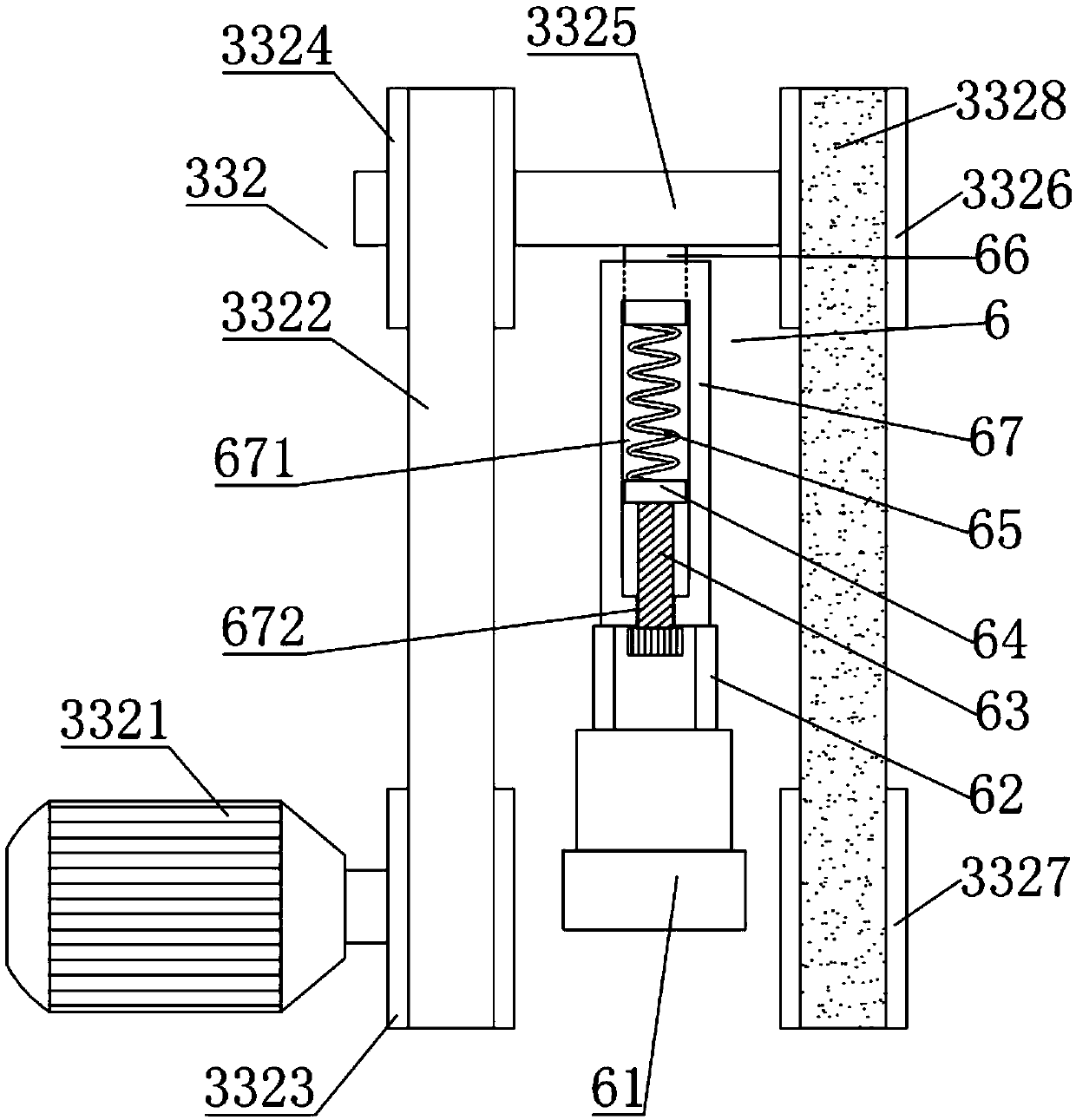

[0029] Such as figure 1 The three-head manipulator water scrub belt machine shown includes a machine platform 1, an electric control cabinet unit 2, a first water scrub belt machine unit 3, a second water scrub belt machine unit 4 and a third water scrub belt machine unit 5. The cross section of the machine platform 1 is circular, the electric control cabinet unit 2 is at the center of the machine platform 1, the first water scrubbing belt machine unit 3, the second water scrubbing belt machine unit 4 and the third water scrubbing belt Machine unit 5 is arranged on the circumference of machine table 1 in the form of annular array; Wherein, described first water scrub belt machine unit 3, the second water scrub belt machine unit 4 and the 3rd water scrub belt machine unit 5 comprise first Linear module 31, manipulator assembly 32 and water abrasive belt machine 33, described water abrasive belt machine 33 is arranged on the machine platform 1, and described first linear module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com