Part drilling and cleaning device

A technology for cleaning devices and parts, applied in the field of parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

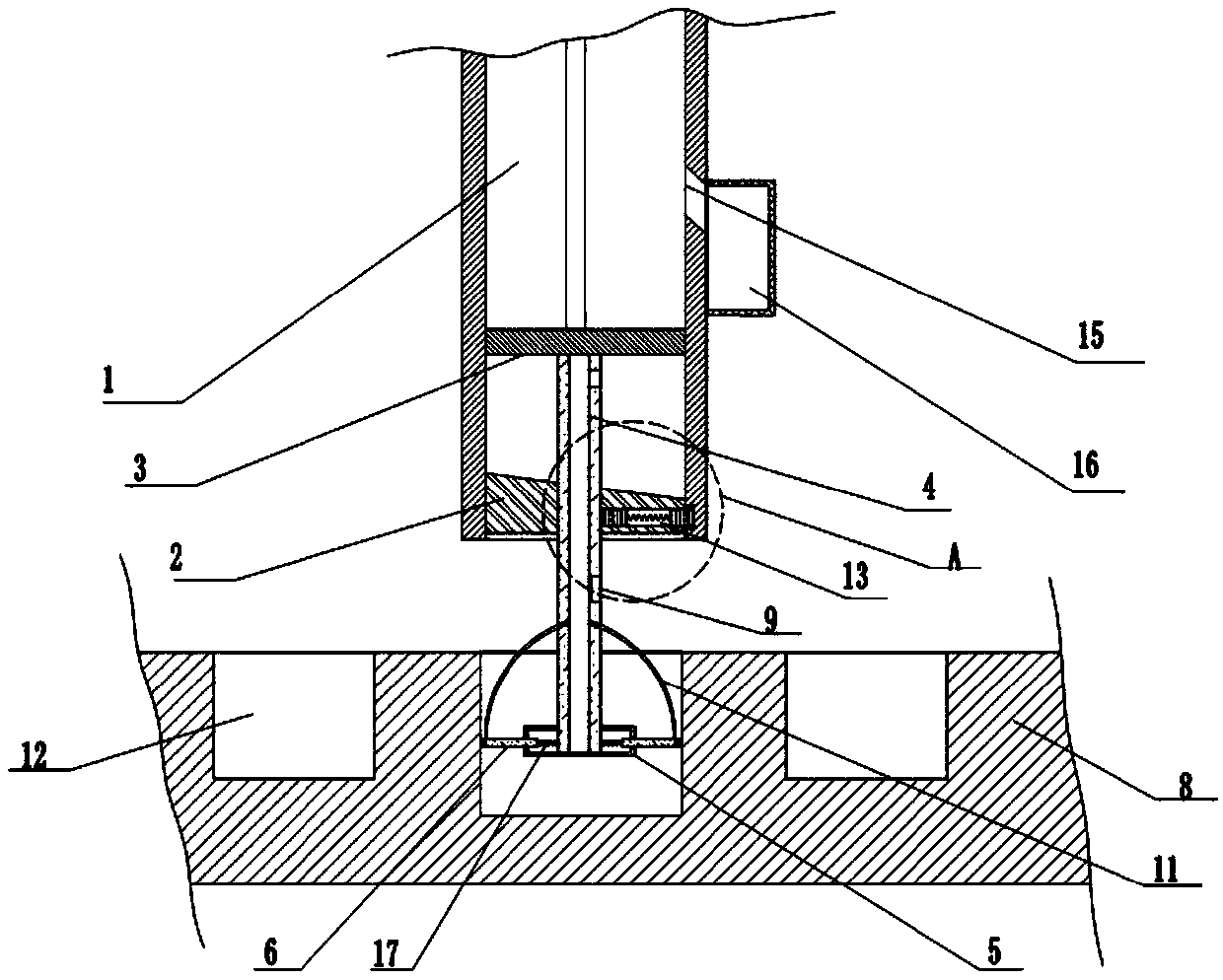

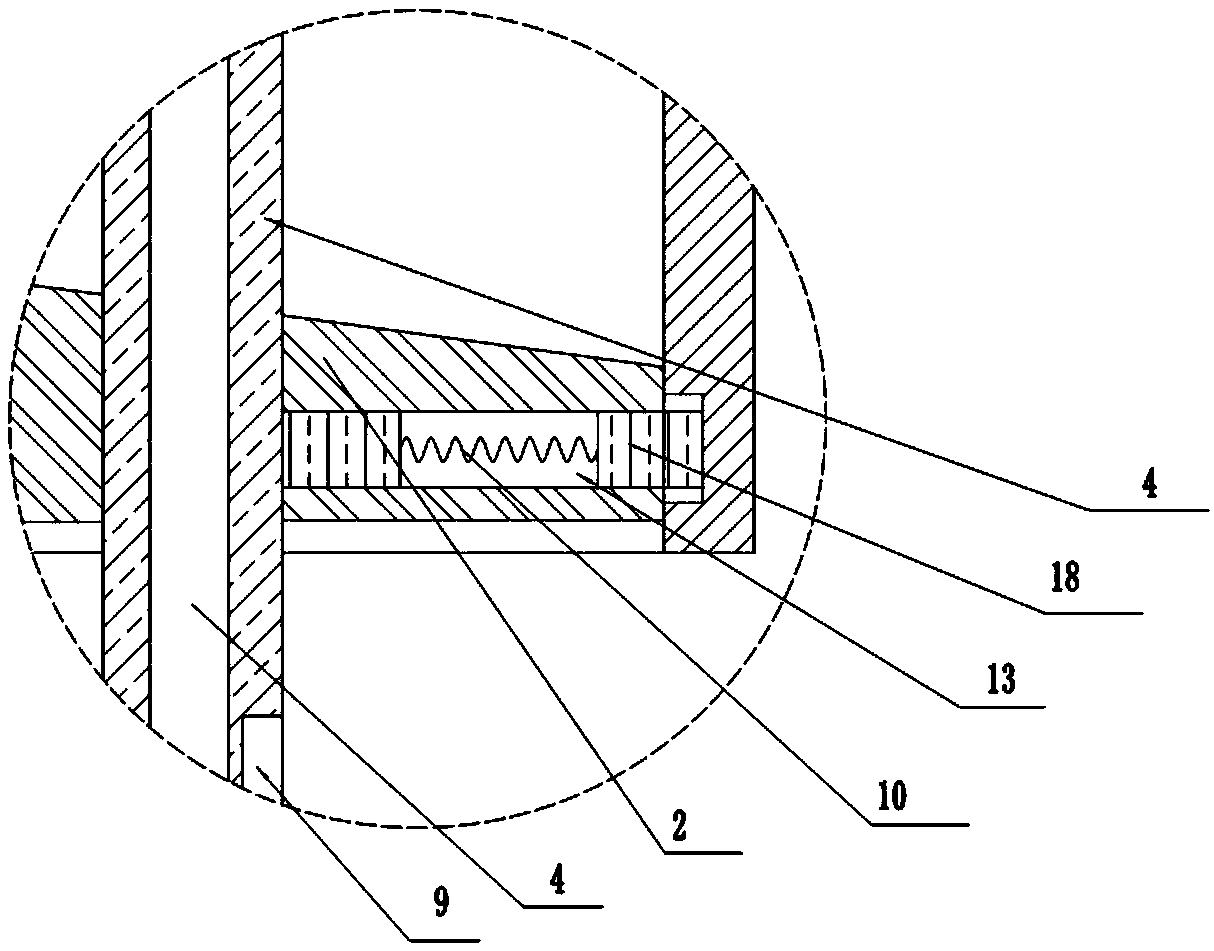

[0021] The reference signs in the drawings of the description include: cleaning box 1, inclined block 2, piston plate 3, connecting rod 4, hollow tube 5, fixed plate 6, rotating plate 7, workbench 8, groove 9, compression spring 10, Air pipe 11 , limiting groove 12 , through hole 13 , cavity 14 , chip outlet 15 , collecting box 16 , first return spring 17 , fixed block 18 , second return spring 19 .

[0022] Examples are attached figure 1 Shown: a parts drilling cleaning device, including a frame, the frame is provided with a cylinder, a cleaning box 1 and a workbench 8 in sequence from top to bottom, the cylinder and the workbench 8 are fixedly connected to the frame, and the cylinder is used as a device The power source of the workbench 8 is provided with a limit groove 12 for different types of parts, and the limit groove 12 is arranged symmetrically with respect to the center li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com