A vacuum drying oven

A vacuum drying oven and drying cabinet technology, which is applied in drying chambers/containers, drying solid materials, local stirring dryers, etc., can solve problems such as low drying efficiency, drug pollution, and reduced drug output, and achieve recycling and protection Sanitation and efficiency improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

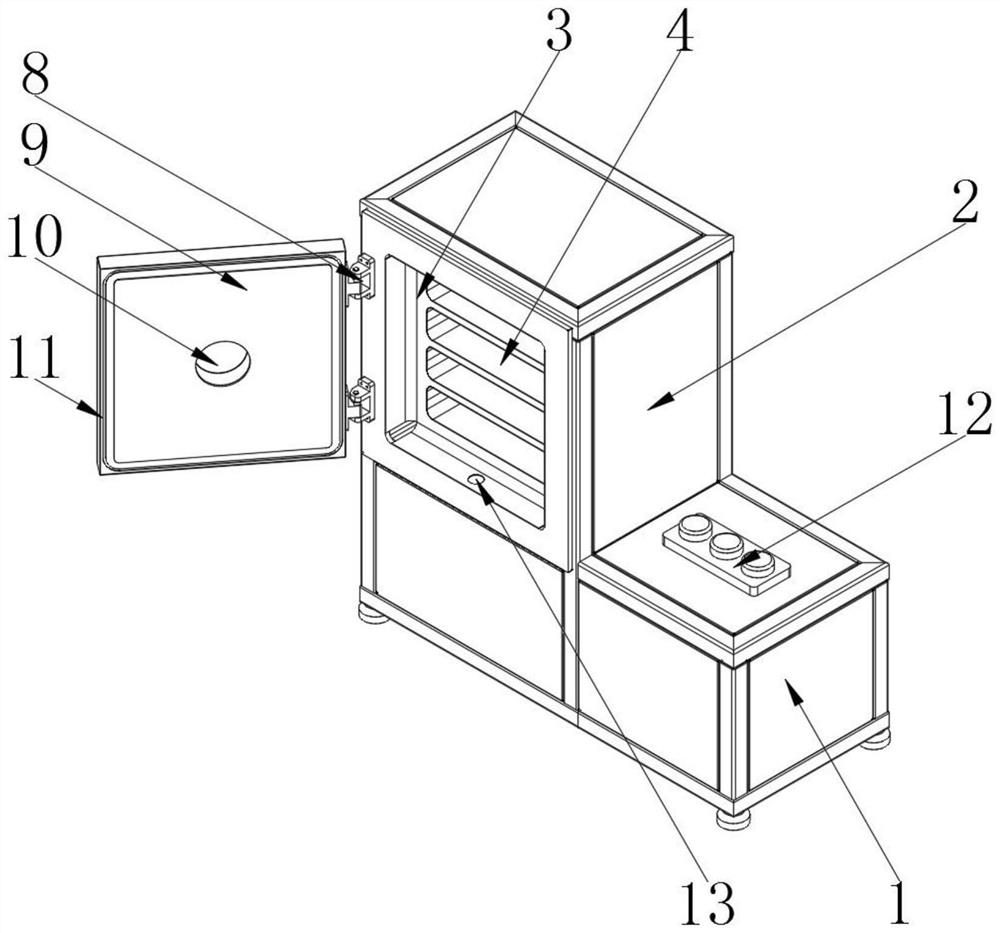

[0050] Example: such as Figure 1-9 As shown, a vacuum drying box includes a base 1 and a main box body 2, a main box body 2 is arranged above the base 1, and a box door 9 is installed on one side of the main box body 2 through a door hinge 8, and the box door The middle part of 9 is embedded with an observation mirror 10. The observation mirror 10 is a transparent mirror for observing the drying condition of the materials inside the main box body 2. The door 9 is surrounded by a sealing strip 11 near the side of the main box body 2. , the sealing strip 11 is used to keep the tightness of the connection between the box door 9 and the main box body 2, keep the vacuum degree inside the drying cabinet 3, and improve the efficiency of material drying. The main box body 2 is equipped with a drying cabinet 3 inside, and the drying cabinet 3 The arc angle between the side close to the box door 9 and the main box body 2 is excessively treated, the mold is pressed and formed, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com