Extrusion roller sleeve heating disassembly device and disassembly method using extrusion roller sleeve heating disassembly device

A technology for squeezing rollers and roller sleeves, which is applied in metal processing, metal processing equipment, manufacturing tools, etc. It can solve the problems of easily damaged roller shafts and low removal efficiency of roller sleeves, and achieve the effects of improving production efficiency and shortening disassembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

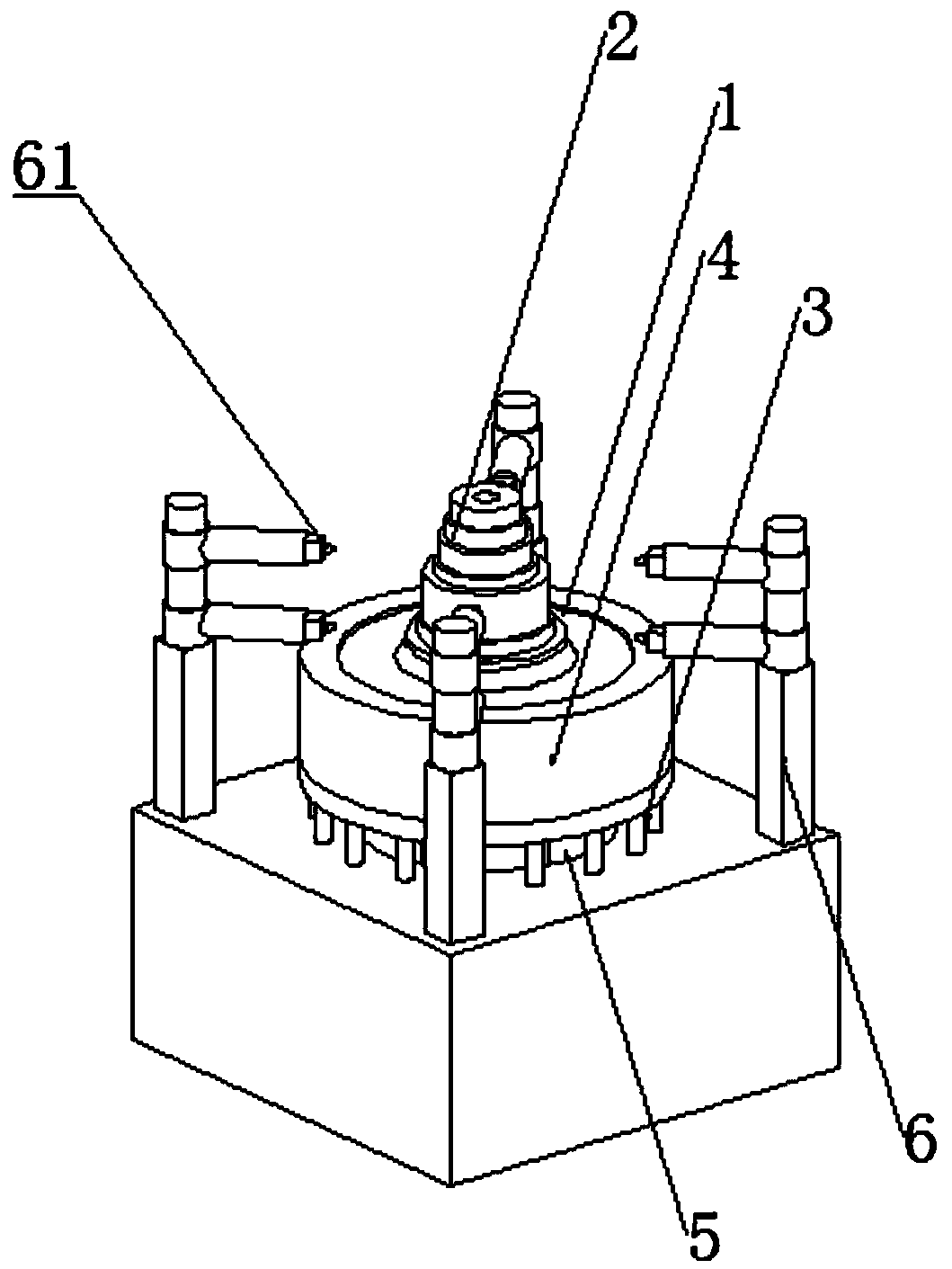

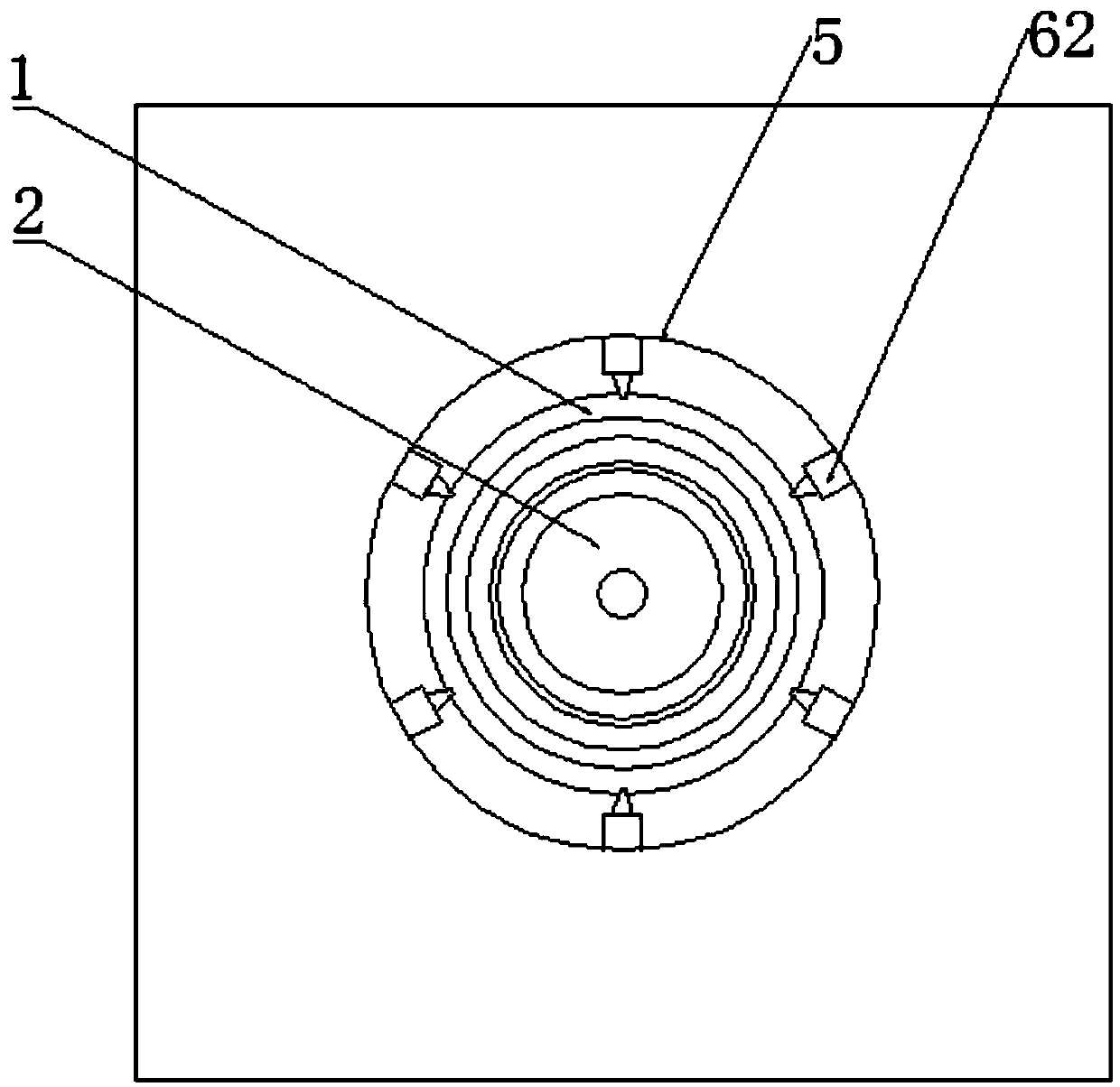

[0041] like Figure 1-6 As shown, the present invention provides the aforementioned thermal removal device for extrusion roll sleeves, which includes a bracket 3 , a covering body 4 , a holding pool 5 and a cooling mechanism 6 . The support 3 can be directly installed on the ground, and a part of the storage pool 5 and the pipeline structure 63 can also be arranged on the ground, or a special base can be included, and a part of the support 3, the storage tank 5 and the pipeline structure 63 can be set on the base.

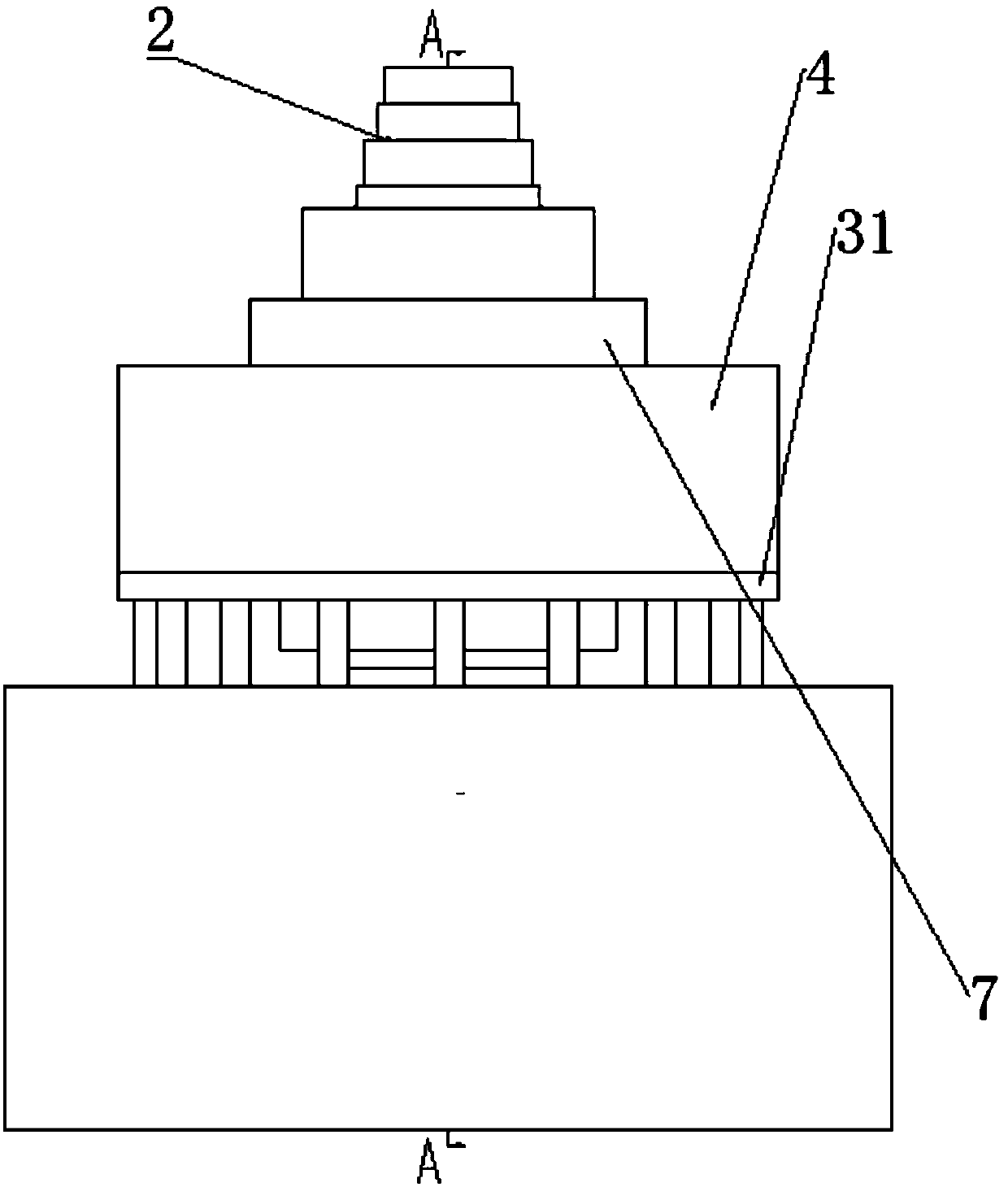

[0042] The upper part of the support 3 is a support ring 31, the diameter of the inner hole of the support ring 31 is larger than the outer diameter of the tubular structure formed by the roller shaft 2 and the heat conducting sheet 7, and a ring is provided on the support 3 that is concentric with the inner hole and is connected to the outer surface of the covering body 4. Locating grooves for radial fit. In this way, it is convenient to place and position the c...

Embodiment 2

[0050] like Figure 3-6 As shown, the structural difference between this embodiment and Embodiment 1 is that a placement tube 51 is fixed at the bottom of the holding pool 5, the placement tube 51 is located below the lower atomizing nozzle 62, and the inner hole of the placement tube 51 Corresponding to the lower part of the roller shaft 2, a buffer mechanism is provided at the bottom of the inner hole. The buffer mechanism can be any existing buffer device, such as a spring plate with a built-in spring, a buffer pad made of elastic material, or an air pressure or hydraulic buffer device. . In this solution, the roller shaft 2 is caught by the placement tube 51, the pair of the roller shaft 2 is placed to topple over, and the impact of the falling of the roller shaft 2 is absorbed by the buffer mechanism to prevent the roller shaft 2 from being damaged. It is more convenient not to use hoisting equipment at the same time when heating.

[0051] As for the thermal removal dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com