Ladle pouring device

A technology of ladle device and pouring ladle, which is applied to equipment for feeding molten metal into molds, casting molten material containers, manufacturing tools, etc., which can solve problems such as high energy consumption and cumbersome process, so as to ensure consistency and avoid pouring Out of the mold, precise pouring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

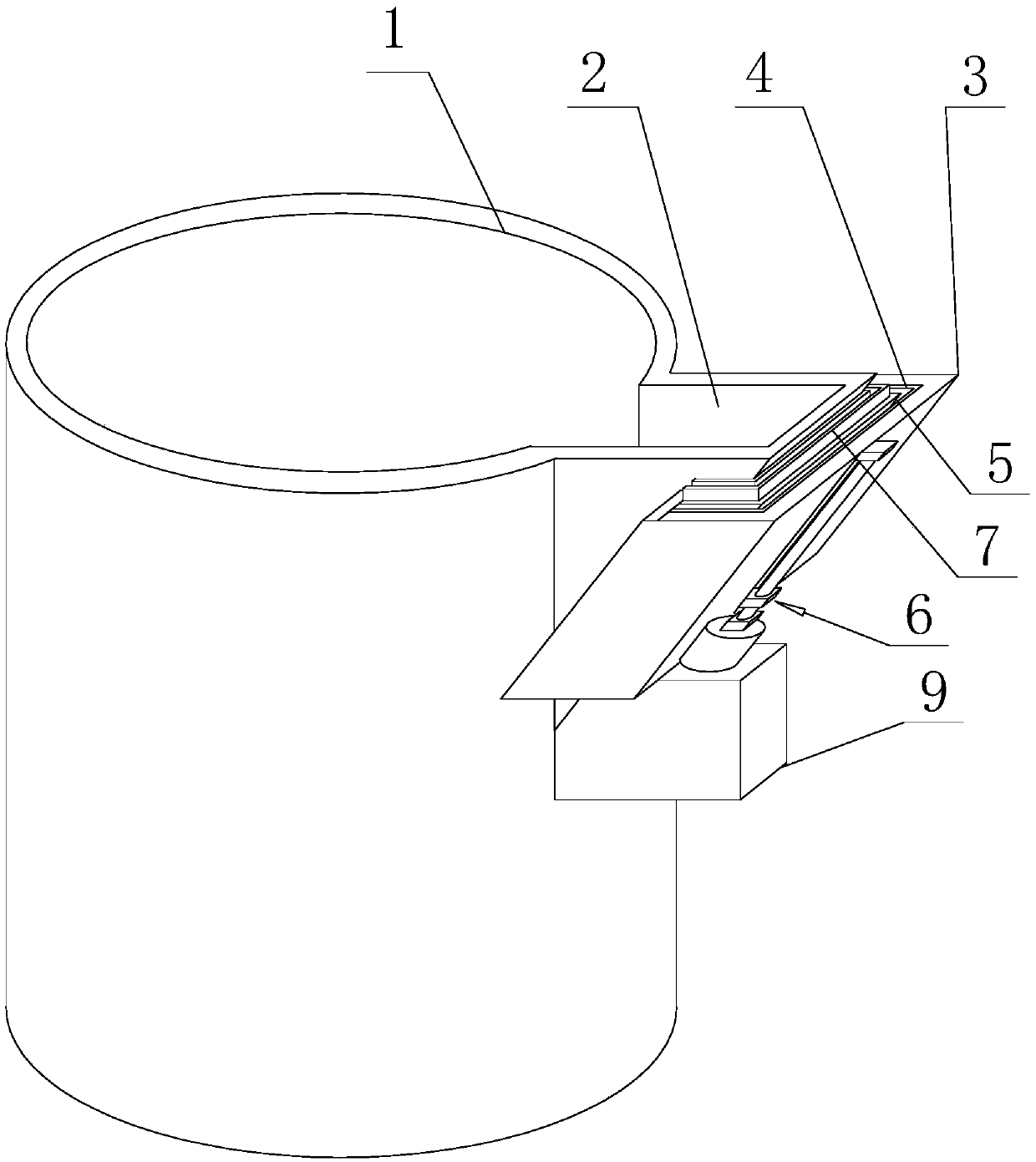

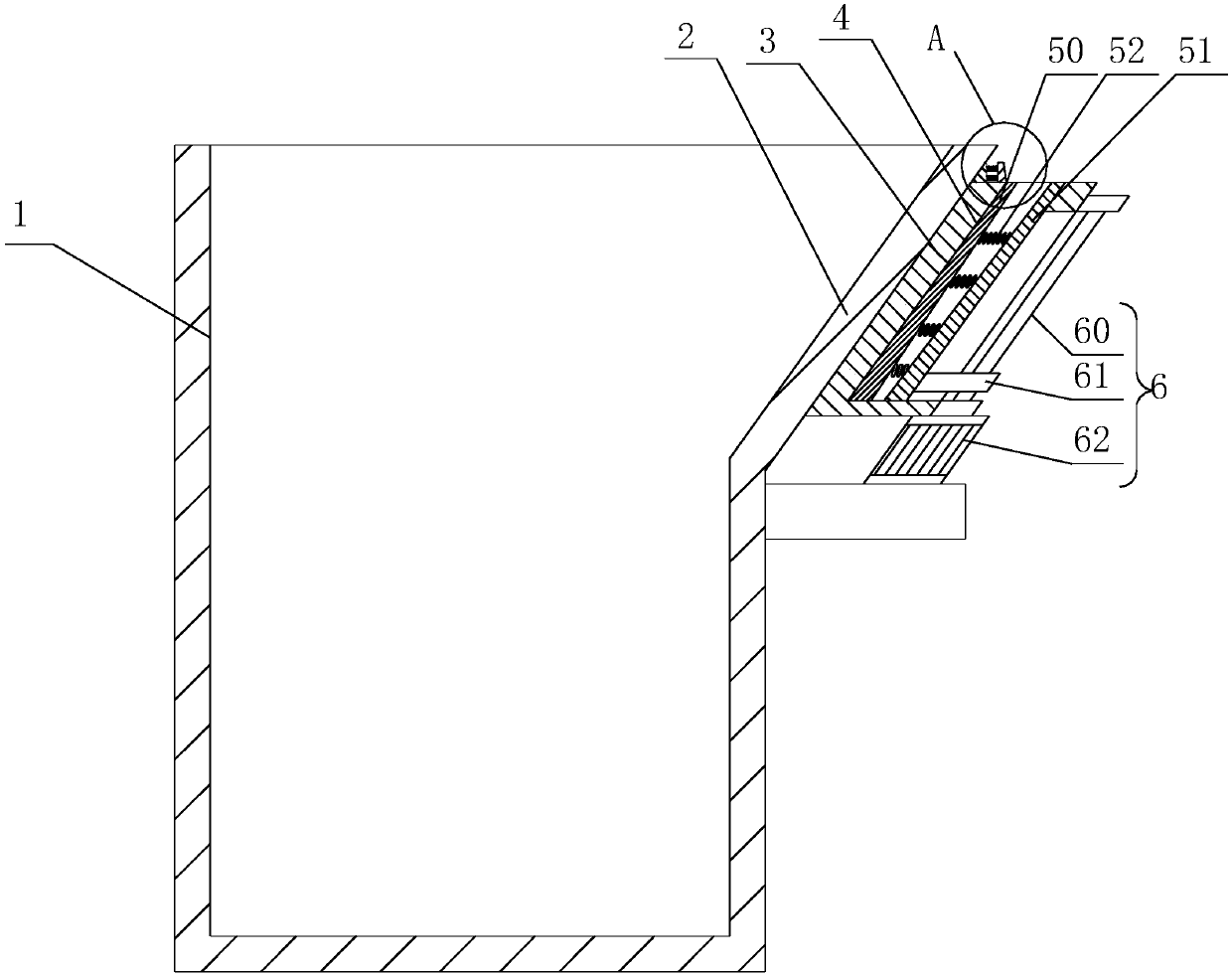

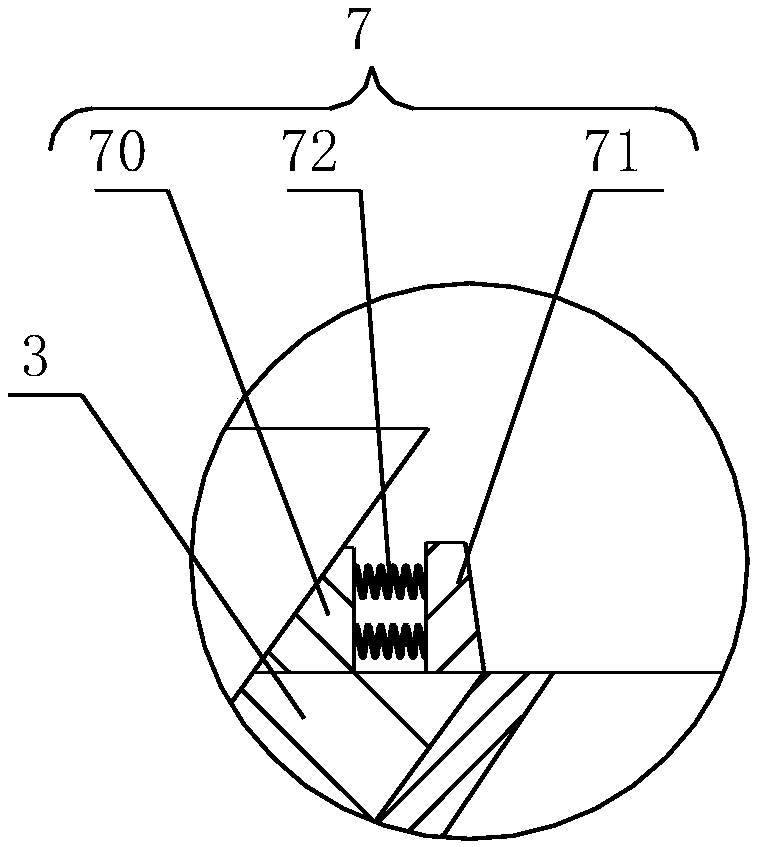

[0024] like Figure 1-6 The ladle device shown includes a ladle body 1, a ladle mouth 2 is provided on the ladle body 1, a guide 3 is provided on the outer wall of the ladle mouth 2, and a deflector 5 is slidably connected to the guide 3, The deflectors 5 are all concave, and the guide 3 has a guide groove 4, the deflector 5 slides in the guide groove 4, the surface of the deflector 5 close to the ladle mouth is parallel to the inner surface of the ladle mouth 2, and the guide The flow plate 5 is connected with the guide member 3 through the sliding mechanism 6 , and the sliding mechanism 6 drives the flow guide plate 5 to move up and down relative to the ladle mouth 2 .

[0025] The sliding mechanism 6 includes a lead screw 60, a slider 61 and a moving element 62, the lead screw 60 is connected to the guide 3 in rotation, the slider 61 is threadedly mounted on the lead screw 60, and the slider 61 is fixedly connected to the deflector 5 , the moving part 62 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com