A separate and connected stamping die turntable for auto parts

A technology for stamping dies and auto parts, applied in the field of auto parts stamping, can solve the problems of lower pass rate of specifications and sizes, affect the matching status of parts and vehicles, fail to reach the quality and precision of auto parts, and achieve a high pass rate of specifications and sizes , Mold placement plate and mold are stable, and the effect of low rebound value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

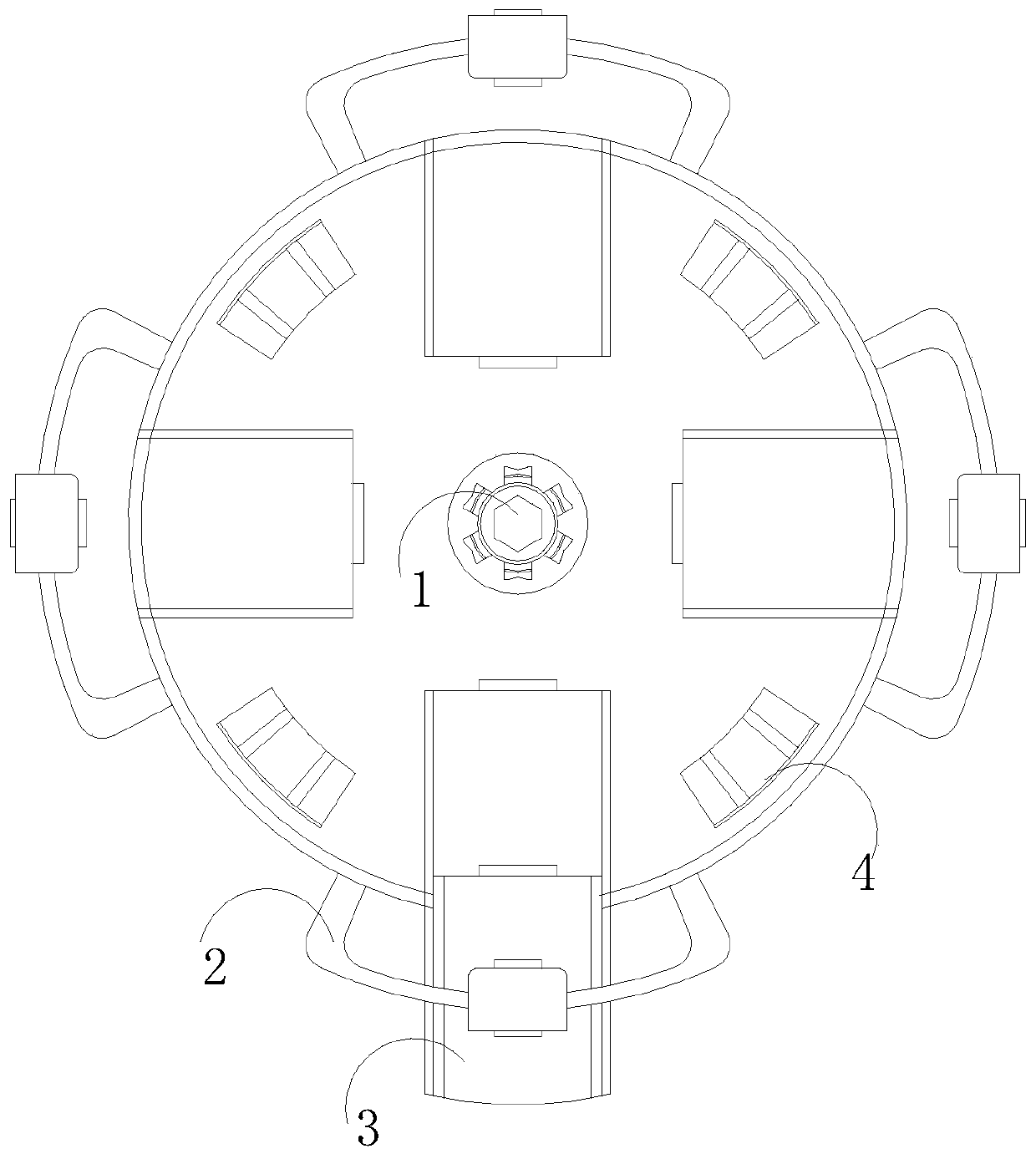

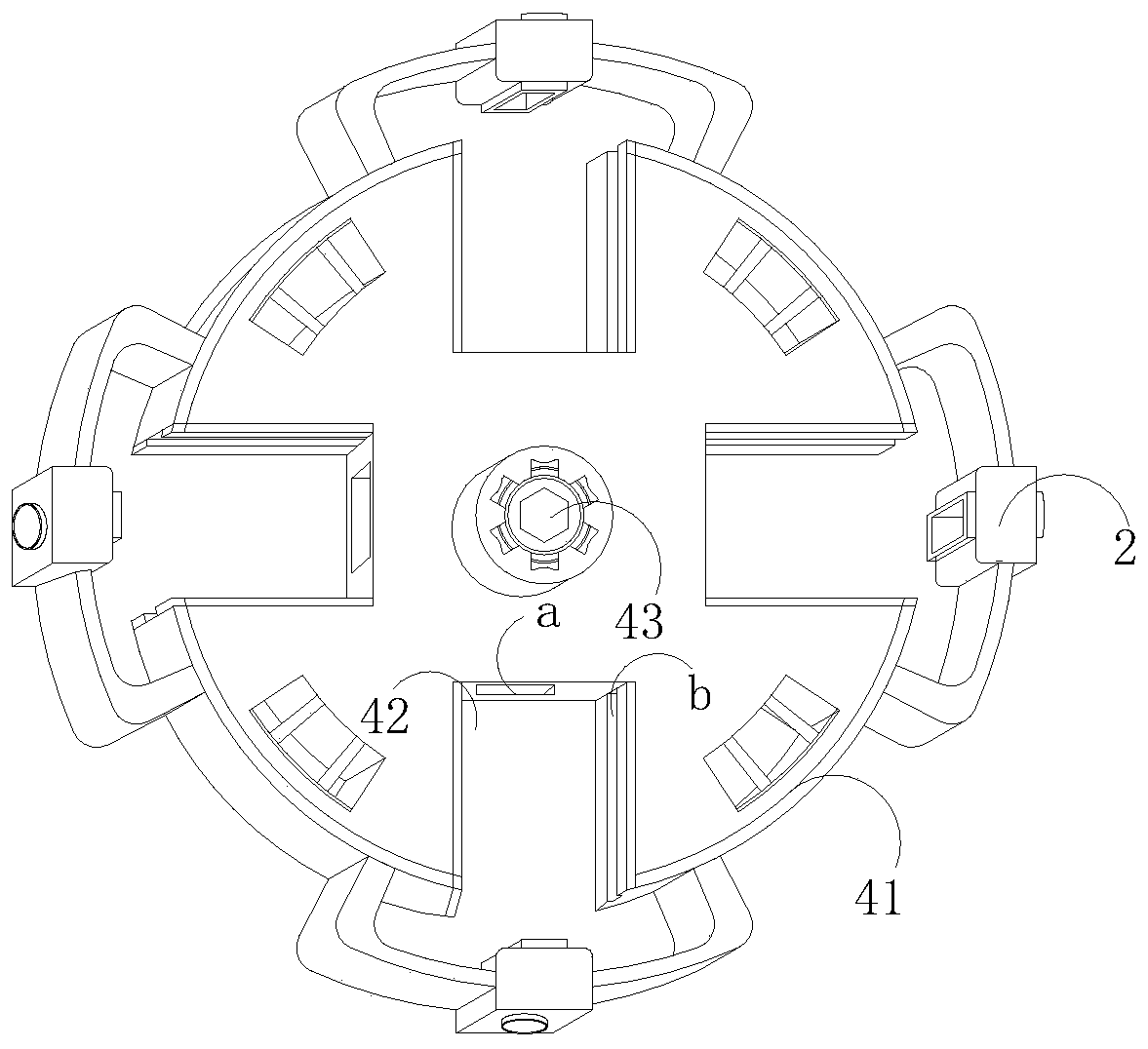

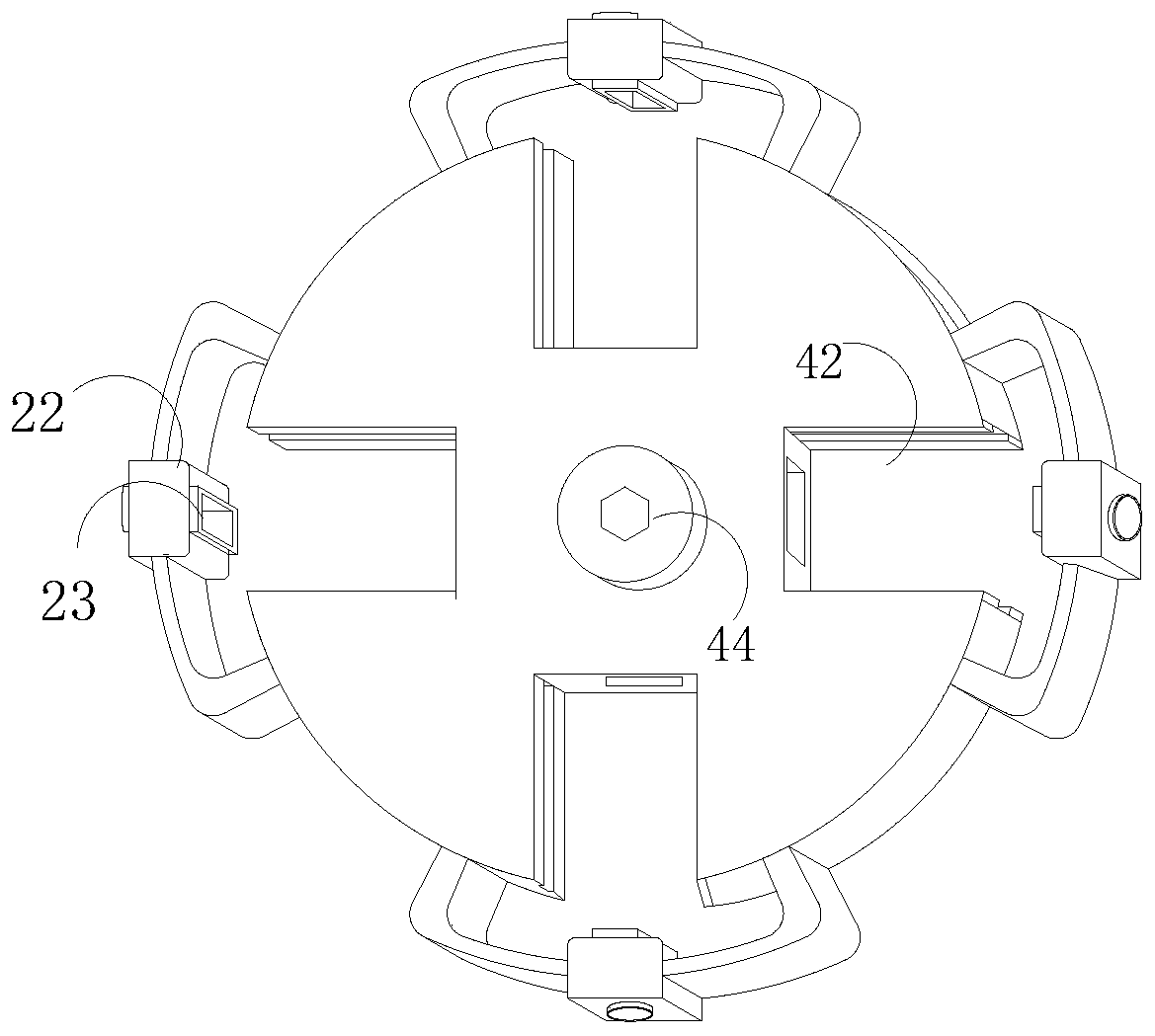

[0023] see Figure 1-Figure 7 , the present invention provides a separate joint stamping die turntable for auto parts, its structure includes a nut 1, a detachable limit rod 2, a mold placement plate 3, a turntable body 4, the turntable body 4 is a flat cylindrical structure And its edge is evenly provided with four mold placement trays 3, the mold placement tray 3 is connected and fixed with the turntable body 4 to form a complete circle, and the two sides of the turntable body 4 opposite to the mold placement tray 3 are equipped with detachable limit rods 2. The detachable limiting rod 2 and the turntable main body 4 are in active cooperation, and the top end surface of the turntable main body 4 is provided with a matching nut 1 in the middle.

[0024] The turntable main body 4 is composed of a special-shaped disk body 41, a mold installation groove 42, a top column 43, and a bottom pipe 44. The outer edge of the special-shaped disk body 41 is evenly opened with a mold insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com