Protection method and device for gas catalyst at room temperature

A gas catalyst and protection device technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of catalyst reduction, loss of catalytic ability, blockage, etc., and achieve the effect of avoiding adsorption and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

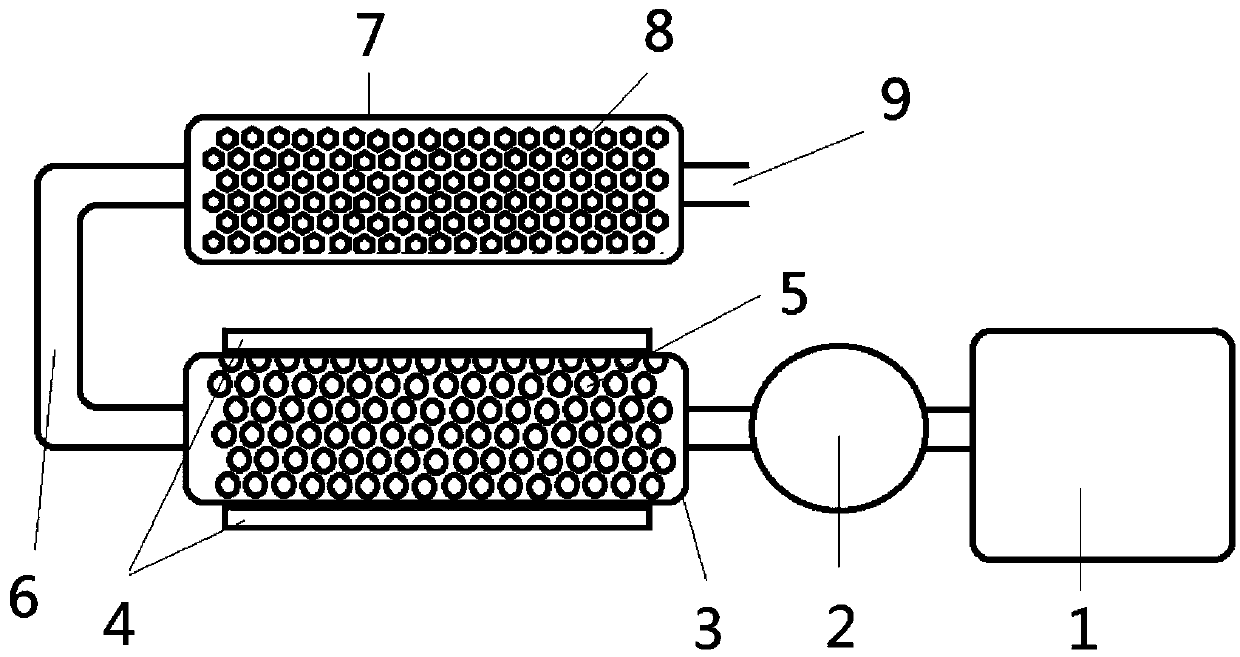

[0013] In the present invention, an adsorbent device is arranged at the front end of the catalyst device, and the gas is purified by the adsorbent before entering the catalyst, so as to realize the protection of the catalyst. like figure 1 As shown, a protection device for gas catalysts at room temperature, including an air pump 2 for transporting gas and air to be treated; an adsorbent barrel 3 for installing adsorbent; installed on the adsorbent barrel, used for heating the adsorbent an electric heater 4; an adsorbent 5 with a porous structure for adsorbing microorganisms, dust, etc.; a hollow connecting pipe 6 for connecting various components; a catalyst barrel 7 for containing a catalyst; Catalyst 8 for catalytic degradation is required in the treatment gas; and exhaust pipe 9 for venting.

[0014] The exhaust gas generated by the exhaust gas generator 1 contains microorganisms, dust and other components harmful to the catalyst. The exhaust gas is transported to the adso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com