Noodle processing, stirring, and cooking device

A chemical device and dough-cooking technology, which is applied to dough mixers, dough processing, mixing/kneading with vertical installation tools, etc., can solve the problems of not being able to process dough in real time, prevent burns, increase the curing speed, and facilitate heat conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

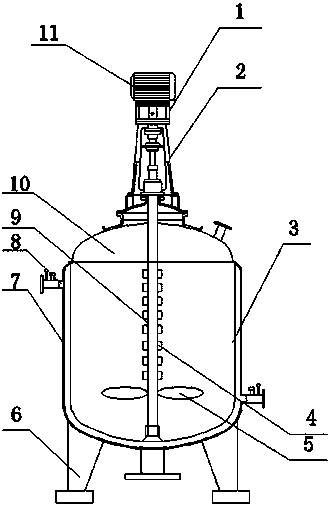

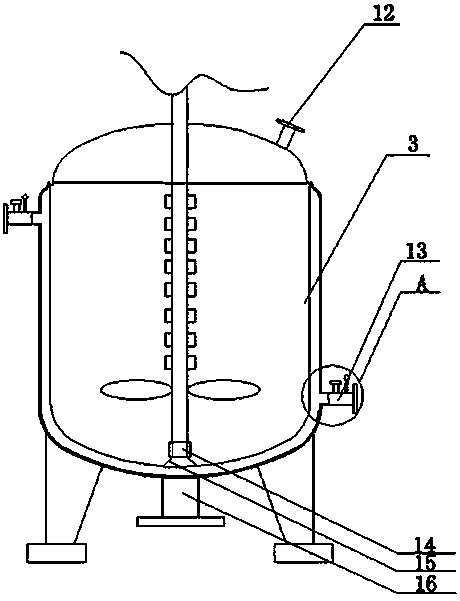

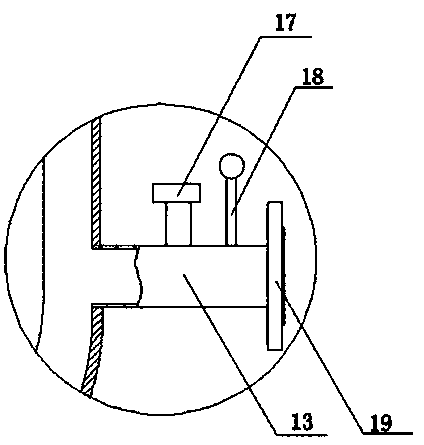

[0019] The present invention as Figure 1 to Figure 3 Shown:

[0020] A noodle processing noodle aging device, comprising a motor 11, a mixing barrel 3, a stirring shaft 9 and a support frame 6, a reducer 1 is arranged under the motor 11, the reducer 11 is connected with the bearing in the frame 2, and the reducer 1 can control the rotation speed of the stirring shaft 9, the frame 2 is arranged under the reducer 1, the stirring shaft 9 is arranged under the frame 2, the stirring shaft 9 is arranged in the mixing barrel 3, and the steam outlet is arranged on one side of the mixing barrel 3 8. The steam outlet 8 discharges the excess gas in the interlayer of the mixing tank 3 in real time, which improves the work efficiency. There is a steam inlet port 13 under one side of the mixing tank 3. The steam inlet port 13 is conducive to the steam in the interlayer of the mixing tank. The transmission can improve the cooking speed of the noodles. The support frame 6 is evenly arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com